Containment

TG - Fire Stopping - Part A.pub - PFPA

TG - Fire Stopping - Part A.pub - PFPA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

26<br />

Fire test data & AS4072/1<br />

compliance<br />

Standard fire test<br />

The fire test method used here locally in both<br />

Australia and New Zealand is<br />

AS1530 Part 4. This test method follows the<br />

basic principles of International Standard<br />

ISO834 Part 1.<br />

All fire stopping systems are required to<br />

have been fire tested to the requirements of<br />

AS1530 Part 4<br />

Essentially the fire testing consists of building<br />

and mounting a representative specimen (or<br />

prototype assembly) onto a fire test furnace<br />

and burning the assembly against<br />

standardised time versus temperature criteria<br />

and with given pressure differential conditions<br />

across the assembly.<br />

Measurement are taken to determine the time<br />

taken to exceed specified criteria for integrity,<br />

insulation and radiation as applicable from<br />

which fire ratings can be determined for<br />

compliance against Building Codes in Australia<br />

and New Zealand.<br />

Fire stopping ’product’ Standard<br />

It is not practical to fire test all the different<br />

configurations of service penetrations, and<br />

based on experience and sound logic,<br />

Australian Standard AS4072 Part 1<br />

(Components for the protection of openings in<br />

fire-resistant separating elements - Service<br />

penetrations and control joints), provides some<br />

standard fire test configurations for electrical &<br />

communication cable penetrations, and<br />

metallic pipe penetrations. After successfully<br />

fire testing these standard configurations a<br />

range of allowable cable and metal pipe types<br />

are automatically approved. The Standard also<br />

provides design guidance, advice relating to<br />

installation, labelling and certification, as well<br />

as some rules relating to variations from fire<br />

tested specimens by way of laboratory<br />

technical assessments and/or formal letters of<br />

opinion.<br />

Field of application for fire stopping products<br />

The culmination of a manufacturer’s fire test<br />

reports and technical assessments / formal<br />

letters of opinions make up a proprietary field<br />

of application for a given fire stopping product.<br />

This field of application or scope of use for a<br />

given fire stopping product is then translated<br />

into manufacturer’s installation instructions for<br />

use in the field by competently trained<br />

installation personnel.<br />

An inside-furnace view of an intumescent fire<br />

damper during testing (above) and a fire<br />

collar test following completion (below)<br />

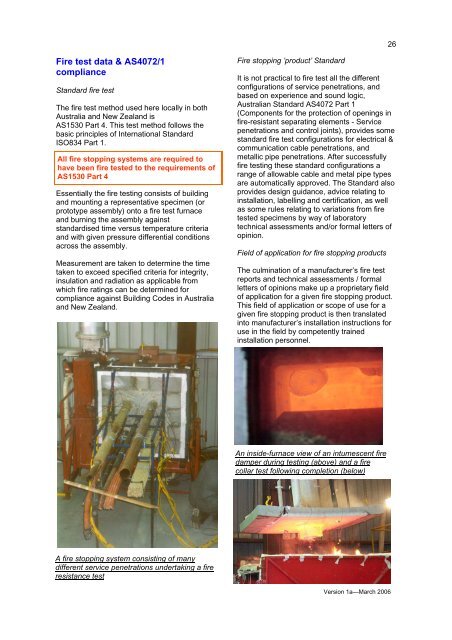

A fire stopping system consisting of many<br />

different service penetrations undertaking a fire<br />

resistance test<br />

Version 1a—March 2006