HOLLOW METAL

HMMA 890-06 Technical Standards - Megamet Industries

HMMA 890-06 Technical Standards - Megamet Industries

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

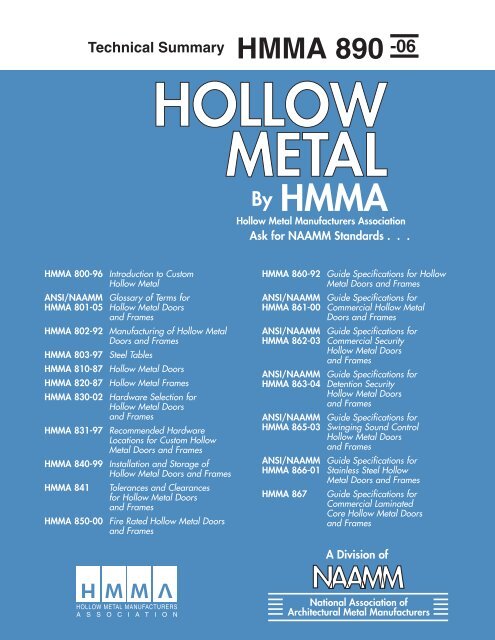

Technical Summary HMMA 890 -06<br />

<strong>HOLLOW</strong><br />

<strong>METAL</strong><br />

By HMMA<br />

Hollow Metal Manufacturers Association<br />

Ask for NAAMM Standards . . .<br />

HMMA 800-96 Introduction to Custom<br />

Hollow Metal<br />

ANSI/NAAMM Glossary of Terms for<br />

HMMA 801-05 Hollow Metal Doors<br />

and Frames<br />

HMMA 802-92 Manufacturing of Hollow Metal<br />

Doors and Frames<br />

HMMA 803-97 Steel Tables<br />

HMMA 810-87 Hollow Metal Doors<br />

HMMA 820-87 Hollow Metal Frames<br />

HMMA 830-02 Hardware Selection for<br />

Hollow Metal Doors<br />

and Frames<br />

HMMA 831-97 Recommended Hardware<br />

Locations for Custom Hollow<br />

Metal Doors and Frames<br />

HMMA 840-99 Installation and Storage of<br />

Hollow Metal Doors and Frames<br />

HMMA 841 Tolerances and Clearances<br />

for Hollow Metal Doors<br />

and Frames<br />

HMMA 850-00 Fire Rated Hollow Metal Doors<br />

and Frames<br />

HMMA 860-92 Guide Specifications for Hollow<br />

Metal Doors and Frames<br />

ANSI/NAAMM Guide Specifications for<br />

HMMA 861-00 Commercial Hollow Metal<br />

Doors and Frames<br />

ANSI/NAAMM Guide Specifications for<br />

HMMA 862-03 Commercial Security<br />

Hollow Metal Doors<br />

and Frames<br />

ANSI/NAAMM Guide Specifications for<br />

HMMA 863-04 Detention Security<br />

Hollow Metal Doors<br />

and Frames<br />

ANSI/NAAMM Guide Specifications for<br />

HMMA 865-03 Swinging Sound Control<br />

Hollow Metal Doors<br />

and Frames<br />

ANSI/NAAMM Guide Specifications for<br />

HMMA 866-01 Stainless Steel Hollow<br />

Metal Doors and Frames<br />

HMMA 867 Guide Specifications for<br />

Commercial Laminated<br />

Core Hollow Metal Doors<br />

and Frames<br />

A Division of<br />

NAAM AMM<br />

National Association of<br />

Architectural Metal Manufacturers

Technical Summary HMMA 890-06<br />

Hollow Metal by HMMA<br />

Table of Contents<br />

HMMA Guide Specifications ...........................................................................................2<br />

Summary information on guide specifications for door and frame<br />

applications available from members of the Hollow Metal<br />

Manufacturers Association, Division of NAAMM.<br />

Fire-Rated Doors...............................................................................................................4<br />

Chart showing fire-rated doors (up to 3 hrs.) available from HMMA<br />

member firms.<br />

Hollow Metal Doors .........................................................................................................5<br />

Depicts some of the wide variation in door styles and construction details<br />

available from HMMA member firms.<br />

Fire-Rated Frames ............................................................................................................6<br />

Chart showing fire-rated frames (up to 3 hrs.) available from HMMA<br />

member firms. Also shows variety of frame profiles.<br />

Frame Construction and Details ....................................................................................7<br />

Depicts a typical frame assembly and details of joints, jamb anchors,<br />

cut-off stops and a field assembled drywall frame.<br />

Hardware Preparation and Locations .........................................................................8<br />

Details on a variety of hardware preparations and recommended<br />

hardware locations.<br />

Manufacturing Tolerances...............................................................................................9<br />

Recommended manufacturing and installation tolerances, plus guides to<br />

proper storage of doors and frames.<br />

The Hollow Metal Manual................................................................................Back Cover<br />

Description of HMMA’s technical publication, The Hollow Metal Manual<br />

(available in hard copy and on CD).

2<br />

HMMA Guide Specifications<br />

Hollow Metal Guide<br />

Specifications<br />

HMMA 860 - Hollow<br />

Metal Doors & Frames<br />

HMMA 861- Commercial<br />

Hollow Metal Doors and<br />

Frames<br />

HMMA 862 - Commercial<br />

Security Hollow Metal<br />

Doors and Frames<br />

HMMA 863 - Detention<br />

Security Hollow Metal<br />

Doors and Frames<br />

HMMA 865 - Swinging<br />

Sound Control Hollow<br />

Metal Doors and Frames<br />

Intended applications<br />

For use in apartment and<br />

other building projects<br />

where traffic is light and<br />

hard usage is not<br />

anticipated<br />

For use in commercial and<br />

industrial projects, where<br />

rigorous use is anticipated<br />

. . . schools, office buildings,<br />

hospitals, industrial<br />

buildings, hotels, convention<br />

centers, nursing homes<br />

Commercial security applications<br />

such as airports, convention<br />

centers, hotels and<br />

offices, and foreign and<br />

domestic buildings such as,<br />

embassies, offices and<br />

barracks.<br />

For use in jails, prisons,<br />

detention centers and secured<br />

areas in hospitals<br />

and courthouses<br />

For applications in TV, radio<br />

and sound studios, the<br />

aters and music rooms<br />

Doors<br />

Face Sheets,<br />

Interior Doors<br />

0.032 in. (0.8mm) 0.042 in. (1.0mm) 0.067 in. (1.7mm) 0.067 in. (1.7mm)<br />

0.093 in. (2.3mm)<br />

0.042 in. (1.0mm)<br />

Face Sheets,<br />

Exterior Doors<br />

0.042 in. (1.0mm) 0.053 in. (1.3mm) 0.067 in. (1.7mm) 0.067 in. (1.7mm)<br />

0.093 in. (2.3mm)<br />

0.042 in. (1.0mm)<br />

Material Type<br />

Pickled and oiled, hot rolled,<br />

or A60 Galvineal<br />

Pickled and oiled, hot rolled,<br />

or A60 Galvineal<br />

Pickled and oiled, hot rolled,<br />

or A60 Galvineal<br />

Pickled and oiled, hot rolled,<br />

or A60 Galvineal<br />

Pickled and oiled, hot rolled,<br />

or A60 Galvineal<br />

Minimum thickness 1³⁄₄ in. (44.4mm) 1³⁄₄ in. (44.4mm) 1³⁄₄ in. (44.4mm) 2 in. (50.8mm)<br />

1³⁄₄ in. (44.4mm)<br />

Stiffeners/Core 0.026 in. (0.6mm) 0.026 in. (0.6mm) 0.042 in. (1.0mm) 0.042 in. (1.0mm) Manufacturer’s standard<br />

Vertical Edges<br />

Continuous weld interlocking<br />

seam, or intermittent<br />

welded exposed seam<br />

Continuous weld Continuous weld Reinforced by 0.123 in.<br />

(3.1mm, 10 ga.) continuous<br />

steel channel, continuous<br />

weld<br />

Manufacturer’s standard<br />

Top and Bottom Edges<br />

0.053 in. (1.3 mm)<br />

continuous recessed steel<br />

channel<br />

0.053 in. (1.3 mm)<br />

continuous recessed steel<br />

channel<br />

0.093 in. (2.3 mm)<br />

continuous recessed steel<br />

channel<br />

0.123 in. (3.1mm) 0.053 in. (3.1mm,)<br />

continuous recessed steel<br />

channel<br />

Frames<br />

Interior Openings<br />

0.042 in. (1.0mm)<br />

- 0.053 in. (1.3mm)<br />

for hollow core wood doors<br />

0.053 in. (1.3mm)<br />

- 0.067 in. (1.7mm)<br />

for openings of more than<br />

4 ft. (1219 mm)<br />

0.093 in. (2.3mm) 0.093 in. (2.3mm)<br />

0.067 in. (1.7mm)<br />

0.067 in. (1.7mm)<br />

Exterior Openings (1) 0.053 in. (1.3mm) 0.053 in. (1.3mm)-<br />

0.067 in. (1.7mm)<br />

for openings over 4 ft.<br />

(1219mm) wide<br />

0.093 in. (2.3mm) 0.093 in. (2.3mm)<br />

0.067 in. (1.7mm)<br />

0.067 in. (1.7mm)<br />

Construction<br />

Welded or knocked-down<br />

with integral stop and trim<br />

Welded units with integral<br />

stop and trim<br />

Welded units with integral<br />

stop and trim<br />

Welded units with integral<br />

stop and trim<br />

Welded units with integral<br />

stop and trim<br />

Floor Anchors<br />

0.053 in. (1.3mm)<br />

welded inside jambs<br />

Same thickness as frame,<br />

welded inside jambs<br />

Same thickness as frame,<br />

welded inside jambs<br />

Same thickness as frame,<br />

welded inside jambs<br />

0.067 in. (1.7mm),<br />

welded inside jamb<br />

Jamb Anchors In masonry walls (9), 0.053<br />

in. (1.3mm) steel or<br />

0.156-in. diam. steel wire.<br />

For stud partitions, 0.042 in.<br />

(1.0mm) steel anchors<br />

welded inside jambs<br />

In masonry walls (9), 0.053<br />

in. (1.3mm) steel or<br />

0.156-in. diam. steel wire.<br />

For stud partitions, 0.042 in.<br />

(1.0mm) steel anchors<br />

welded inside jambs<br />

In masonry walls (10), 0.067<br />

in. (1.7mm) steel or<br />

0.156-in. diam. steel wire.<br />

For stud partitions, 0.053 in.<br />

(1.3mm) steel anchors<br />

welded inside jambs<br />

Same thickness as frame In masonry walls (11), 0.053<br />

in. (1.3mm) steel or<br />

0.156-in. dia. steel wire.<br />

For stud partitions, 0.042 in.<br />

(1.0mm) steel anchors<br />

welded inside jambs<br />

For complete specifications See HMMA 860 See HMMA 861 See HMMA 862 See HMMA 863 See HMMA 865

HMMA Guide Specifications<br />

3<br />

Hollow Metal Guide<br />

Specifications<br />

Intended applications<br />

Face Sheets,<br />

Interior Doors<br />

Face Sheets,<br />

Exterior Doors<br />

Material Type<br />

Minimum thickness 1³⁄₄ in. (44.4mm) 1³⁄₄ in. (44.4mm)<br />

Stiffeners/Core<br />

Vertical Edges<br />

Top and Bottom Edges<br />

Interior Openings<br />

Exterior Openings<br />

Construction<br />

Floor Anchors<br />

Jamb Anchors<br />

Doors<br />

Type 304 or 316<br />

Stainless Steel<br />

HMMA 866 HMMA 867<br />

For specialized applications<br />

where corrosion resistance<br />

beyond that of commercial<br />

hollow metal, or where<br />

aesthetics is of primary<br />

concern<br />

Frames<br />

For commercial applications<br />

where moderate use<br />

is anticipated such as: office<br />

buildings, convention<br />

centers, and industrial<br />

buildings<br />

0.042 in. (1.0mm) 0.032 in. (0.8mm)<br />

0.042 in. (1.0mm) 0.042 in. (1.0mm)<br />

0.026 in. (0.6mm) Welded<br />

Stiffener or Laminated Core<br />

Welded or Exposed Seam<br />

Closed with 0.053 in.<br />

(1.3mm) continuous recessed<br />

0.053 in. (1.3mm) - 0.067<br />

in. (1.7mm) for openings<br />

over 4 ft. (1219mm) wide<br />

0.053 in. (1.3mm) – 0.067<br />

in. (1.7mm) for openings<br />

over 4 ft. (1219mm) wide<br />

Welded K.D. or slip-on with<br />

integral stop and trim<br />

0.067 in. (1.7mm) welded<br />

inside jambs<br />

In masonry walls (9), 0.053<br />

in. (1.3mm) steel or 0.156-<br />

in. diam. steel wire. For stud<br />

partitions, 0.042 in.<br />

(1.0mm) steel anchors<br />

secured inside jambs<br />

Pickled and oiled, hot rolled,<br />

or A60 Galvineal<br />

Laminated Core<br />

Welded or Exposed Seam<br />

Closed with 0.053 in.<br />

(1.3mm) continuous recessed<br />

0.042 in. (1.0mm) for<br />

hollow core wood doors –<br />

0.053 in. (1.3mm)<br />

0.053 in. (1.3mm)<br />

Welded K.D. or slip-on with<br />

integral stop and trim<br />

0.042 in. (1.0mm) welded<br />

inside jambs<br />

In masonry walls (9), 0.053<br />

in. (1.3mm) steel or 0.156-<br />

in. diam. steel wire. For stud<br />

partitions, 0.042 in.<br />

(1.0mm) steel anchors<br />

secured inside jambs<br />

For complete specifications See HMMA 866 See HMMA 867<br />

General Notes<br />

Materials: For doors and frames – commercial quality, level, cold-rolled<br />

steel conforming to ASTM A 1008/A 1008M or hot-rolled, pickled and<br />

oiled steel conforming to ASTM A 1011/A 1011M or stainless steel<br />

conforming to ASTM A 666, Type 304 or 316. Material thicknesses<br />

listed in chart are minimums. Where recommended in the guide specifications,<br />

use zinc-coated steel conforming to ASTM A 653 / A 653M.<br />

Testing and Performance: HMMA 861 requires the following test:<br />

Performance Test for Steel Doors and Hardware Reinforcings (ANSI<br />

A250.4). HMMA 862 incorporates testing procedures and performance<br />

requirements promulgated by NILECJ for class IV doors (ASTM<br />

F 476) including Jamb/Wall Stiffness Performance, Door Impact Test,<br />

Door and Glazing Panel Impact Resistance Performance, (new test)<br />

and SD-STD-01.01 (Rev G) or LPS 1175: Issue 5 standards for Forced<br />

Entry and Ballistic Resistance Testing. HMMA 863 requires the<br />

following tests: Static Load test; Rack test; Impact test; Edge Crush test;<br />

Side-light frame test; and multiple light frame test under ASTM F 1450<br />

and F 1592. Bullet Resistance testing, where applicable, is performed<br />

in accordance with UL-752. Manufacturers must submit independent<br />

laboratory reports certifying performance required by these tests on<br />

sample doors and frames as specified in the standards. HMMA 867<br />

requires the following test: Performance Test for Steel Doors and Hardware<br />

Reinforcings (ANSI A250.4).<br />

Reference Notes:<br />

(1) Face sheets for ext. doors and for frames for ext. openings to<br />

have zinc coating applied by hot-dip process conforming to<br />

ASTM A 653/A 653M (A60 or G60) with coating weight not<br />

less than 0.60 oz. per sq. ft. (0.30 oz. per sq. ft. per side)<br />

(2) Continuous vertical formed steel sections, 6" apart, spot welded<br />

to both face sheets 5" o.c.<br />

(3) Vertical int. webs no more than 4" o.c., spot welded to both faces<br />

mimimum 3" o.c.<br />

(4) Jamb edges of door reinforced with continuous steel channel not<br />

less than 0.093 in. (2.3mm, 12 ga.)<br />

(5) Top end channel fitted with additional flush closing channel of not<br />

less than 0.053 in. (1.3mm, 16 ga.) welded in place at corners<br />

and center.<br />

(6) Where glass thickness dictates, 0.093 in. (2.3mm, 12 ga.) offset<br />

face-mounted glass stops shall be used. Where shown, pressed<br />

steel angle glazing stops, no less than 0.123 in. (3.1mm, 10 ga.)<br />

shall be provided.<br />

(7) Louvers for ext. doors to have steel-framed screens secured to<br />

back of louvers; wire screen of 1 /4" grid galvanized hardware<br />

cloth.<br />

(8) For speaking devices and food pass openings, refer to HMMA<br />

863.<br />

(9) Frames for installation in masonry walls provided with adjustable<br />

jamb anchors of T-strap or stirrup-and-strap or wire type. Stirrup<br />

straps not less than 2"X10" in size.<br />

(10) Frames for installation in masonry walls provided with adjustable<br />

jamb anchors of T-strap or wire type. Straps not less than 2"X10"<br />

in size.<br />

(11) Frames for installation in masonry walls provided with adjustable<br />

jamb anchors of strap and stirrup type. Straps not less than<br />

2"X10" in size.<br />

(12) Provided at all hardware mortises on frames that are specified to<br />

be grouted.<br />

(13) Interior frames may be provided with snap-on glazing stops.<br />

(14) Where shown in non-security locations, 0.067 in. (1.7mm, 14<br />

ga.) pressed steel channel provided.<br />

(15) For nominal door widths over 4 ft. (1219mm) frame material<br />

thickness of 0.067 in. (1.7mm, 14 ga.) is recommended.

4<br />

HMMA Fire-Rated Doors<br />

HMMA leading the way in joint fire door testing, research and development;<br />

hose stream testing, positive pressure testing to UBC 7-2 and ISO 3008.<br />

Fire Door Features<br />

Hourly<br />

Rating<br />

Face<br />

Sheets<br />

Single Door or Pairs,<br />

Active Leaf of Pair Inactive Leaf<br />

Door<br />

Description<br />

3-hour<br />

1-¹⁄₂-hour<br />

³⁄₄-hour<br />

Maximum<br />

Door Opening (2)<br />

Sizes<br />

Swinging Single<br />

Swinging in Pairs<br />

0.093 in. (2.3mm)<br />

0.067 in. (1.7mm)<br />

0.053 in. (1.3mm)<br />

0.042 in. (1.0mm)<br />

Latch Throw<br />

Fire Exit<br />

Hardware<br />

Latch<br />

Mortise<br />

Rim<br />

Vertical Rods,<br />

Concealed or Exposed<br />

Vertical Rods,<br />

Concealed or Exposed<br />

Open Back Strike<br />

Automatic Flush Bolt<br />

Manual Flush Bolt<br />

With Astragal<br />

Without Astragal (up to 1-¹⁄₂ hours)<br />

Basic<br />

Fire<br />

Door<br />

Temperature<br />

Rise Fire-<br />

Rated<br />

450°<br />

450°<br />

250°<br />

250°<br />

F<br />

F<br />

F<br />

F<br />

Double<br />

Egress<br />

Stainless<br />

Steel<br />

Dutch<br />

Louvered<br />

Sound<br />

Radiation<br />

Retarding<br />

• • • • • • •<br />

• • • • • •<br />

•<br />

•<br />

•<br />

• • • • • • •<br />

• • • • • • •<br />

•<br />

• •<br />

•<br />

• • • • • • •<br />

• • • • • • •<br />

•<br />

• •<br />

• •<br />

• •<br />

•<br />

•<br />

• • •<br />

• • •<br />

4'0"x8'0"<br />

5'0"x12'0"<br />

4'0"x10'0"<br />

8'0"x8'0"<br />

8'0"x8'0"<br />

8'0"x10'0"<br />

10'0"x12'0"<br />

4'0"x10'0"<br />

5'0"x12'0"<br />

8'0"x10'0"<br />

10'0"x12'0"<br />

4'0"x8'0"<br />

8'0"x8'0"<br />

8'0"x10'0"<br />

4'0"x8'0"<br />

8'0"x8'0"<br />

4'0"x8'0"<br />

4'0"x8'0"<br />

8'0"x8'0"<br />

4'0"x8'0"<br />

4'0"x8'0"<br />

8'0"x7'2"<br />

8'0"x8'0"<br />

• • •<br />

• • • • • • •<br />

•<br />

•<br />

•<br />

•<br />

•<br />

• • • •<br />

• • • • • • •<br />

•<br />

•<br />

•<br />

• •<br />

•<br />

• • • • • • •<br />

•<br />

•<br />

• • • • • • • • • • • • • • •<br />

• • • • • • •<br />

• • • • • •<br />

• • • • • • •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• • •<br />

• • • • •<br />

• • • • • • •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• • •<br />

¹₂"<br />

³₄"<br />

³₄"<br />

¹₂"<br />

¹₂"<br />

³₄"<br />

³₄"<br />

⁵⁄₈"<br />

³₄"<br />

⁵⁄₈"<br />

³₄"<br />

¹₂"<br />

³₄"<br />

³₄<br />

³₄<br />

³₄"<br />

¹⁄₂"<br />

³₄"<br />

¹⁄₂"<br />

¹⁄₂"<br />

³₄"<br />

³₄"<br />

• • • • • • •<br />

• • • • • •<br />

• • • • • • •<br />

• •<br />

•<br />

• •<br />

•<br />

• • • • • • •<br />

• •<br />

• •<br />

• • •<br />

• • •<br />

• • • • • • •<br />

• • • • • • •<br />

• • •<br />

• • • • • • •<br />

• • • • • • •<br />

•<br />

•<br />

•<br />

• • • • • • •<br />

•<br />

•<br />

•<br />

• • • • • • •<br />

• • •<br />

• • • • • • •<br />

•<br />

•<br />

• • •<br />

• • • • • • •<br />

•<br />

•<br />

• • •<br />

• • • • • • •<br />

•<br />

•<br />

•<br />

•<br />

•<br />

• •<br />

•<br />

•<br />

•<br />

Pressure<br />

Resistant<br />

•<br />

•<br />

•<br />

3'6"x7'2"<br />

•<br />

•<br />

³₄"<br />

•<br />

•<br />

•<br />

The HMMA Division of NAAMM and its 60-plus member firms are leaders in fire door<br />

research and development. Through their ongoing joint fire test program, these hollow metal<br />

manufacturers construct and test a variety of fire-rated door and frame configurations. The<br />

most recent successful testing has been completed under “positive pressure” furnace conditions<br />

in accordance with UBC 7-2 and ISO 3008.

HMMA Hollow Metal Doors<br />

NAAMM's HMMA member companies offer wide varations in door design and construction.<br />

Illustrated below are just a few of the almost limitless designs available to meet hollow metal door requirements.<br />

5<br />

Flush<br />

Vision<br />

Light<br />

Narrow<br />

Light<br />

Glass<br />

w/Louver<br />

Glass<br />

w/Muntin<br />

Two<br />

Louvers<br />

Dutch<br />

w/Glass<br />

Four<br />

Visions<br />

Glass<br />

Extra<br />

(Features)<br />

Stiffener<br />

Core Constructions<br />

Top Edge Detail<br />

Insulation<br />

Face<br />

sheet<br />

Standard<br />

inverted<br />

channel<br />

Flush<br />

closing channel<br />

Sealed if desired<br />

Steel<br />

Stiffened<br />

Honeycomb<br />

“Kraft” paper<br />

Foam<br />

Mineral<br />

Board<br />

Flush Transom Panel<br />

Common Beveled Edge Profiles<br />

Channel or<br />

angle may be<br />

used in place<br />

of plate<br />

Edge Seams Welded or Exposed<br />

Representative Stiffener Sections<br />

Bottom Edge Detail<br />

Welded<br />

at ends<br />

Hat Sections<br />

Channel<br />

Zee<br />

Standard<br />

inverted<br />

channel<br />

Flush<br />

closing<br />

channel<br />

Automatic<br />

Weatherstrip<br />

Glass Lights<br />

Muntins<br />

Flush Overlap Security<br />

Flush<br />

Recessed

6<br />

HMMA Fire-Rated Frames<br />

HMMA leading the way in joint fire door testing, research and development;<br />

hose stream testing, positive pressure testing to UBC 7-2 and ISO 3008.<br />

Fire Frame Features<br />

Hourly<br />

Rating<br />

(3) Wall<br />

Frame<br />

Description<br />

3-hour<br />

1-¹₂-hour<br />

³₄-hour<br />

Maximum<br />

Frame Opening (2)<br />

Sizes<br />

Swinging Single<br />

Swinging in Pairs<br />

0.093 in. (2.3mm, 12 ga.)<br />

0.067 in. (1.7mm, 14 ga.)<br />

0.053 in. (1.3mm, 16 ga.)<br />

New Masonry<br />

Existing Masonry<br />

Steel Studs<br />

Wood Studs<br />

Adjustable Floor Knee<br />

Cut-off Stop<br />

Stainless Steel<br />

Maximum<br />

Door or Window (2)<br />

Opening Sizes<br />

Maximum Transom<br />

Light or Panel (1, 2)<br />

Opening Sizes<br />

Maximum Side<br />

Light or Panel (1, 2)<br />

Opening Sizes<br />

Three-Sided<br />

Frame<br />

• • • •<br />

• •<br />

•<br />

4'0"x10'0"<br />

5'0"x10'0"<br />

8'0"x10'0"<br />

10'0"x12'0"<br />

• • •<br />

•<br />

• •<br />

• •<br />

• • •<br />

• •<br />

•<br />

•<br />

• • • •<br />

• • • •<br />

• • • •<br />

• • •<br />

• • • •<br />

• •<br />

• • • •<br />

4'0"x10'0"<br />

8'0"x10'0"<br />

10'0"x12'0"<br />

4'0"x10'0"<br />

Double<br />

Egress<br />

•<br />

•<br />

•<br />

8'0"x10'0"<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

8'0"x8'0"<br />

Transom<br />

with Bar and<br />

1³⁄₄" Panel<br />

• •<br />

• •<br />

• • • •<br />

4'0"x11'0"<br />

8'0"x11'0"<br />

5'0"x12'0"<br />

10'0"x12'0"<br />

• •<br />

• •<br />

• •<br />

• •<br />

• •<br />

•<br />

•<br />

•<br />

•<br />

• • • •<br />

• • • •<br />

• • • •<br />

• •<br />

• • • •<br />

• •<br />

• •<br />

• •<br />

3'6"x7'2"<br />

7'0"x7'2"<br />

3'6"x3'6"<br />

7'0"x3'0"<br />

4'0"x4'0"<br />

8'0"x4'0"<br />

Transom<br />

with Bar and<br />

³⁄₈" -³⁄₄" Panels<br />

• • • •<br />

• •<br />

• •<br />

•<br />

4'0"x10'0"<br />

8'0"x10'0"<br />

5'0"x12'0"<br />

10'0"x12'0"<br />

• •<br />

• •<br />

• •<br />

• •<br />

• •<br />

•<br />

•<br />

•<br />

•<br />

• • • •<br />

• • • •<br />

• • • •<br />

• •<br />

• • • •<br />

• •<br />

• •<br />

• •<br />

4'0"x10'0"<br />

8'0"x10'0"<br />

10'0"x12'0"<br />

4'0"x2'8"<br />

8'0"x2'8"<br />

Transom with<br />

No Bar and<br />

1"-³⁄₄" Panels<br />

• •<br />

• •<br />

4'0"x11'4"<br />

8'0"x11'2"<br />

•<br />

•<br />

• •<br />

• •<br />

• •<br />

• •<br />

•<br />

• •<br />

• •<br />

• •<br />

• •<br />

• •<br />

4'0"x9'0"<br />

8'0"x8'0"<br />

4'0"x4'6"<br />

8'0"x4'0"<br />

Multiple<br />

Swing Door<br />

Opening<br />

•<br />

• •<br />

12'0"x8'0"<br />

13'6"x12'0"<br />

• •<br />

• •<br />

• •<br />

•<br />

• •<br />

• •<br />

• •<br />

•<br />

•<br />

•<br />

8'0"x8'0"<br />

Fire Door<br />

With<br />

Transom and<br />

Side Light or<br />

Panel<br />

• •<br />

• • • • •<br />

13'6"x12'0"<br />

13'6"x12'0" (4)<br />

• •<br />

• •<br />

• • •<br />

• • •<br />

• • •<br />

• • •<br />

• • •<br />

• • •<br />

• • •<br />

• • •<br />

• • •<br />

4'0"x10'0"<br />

8'0"x10'0"<br />

4'0"x10'0"<br />

8'0"x10'0"<br />

4'6"x4'6"<br />

3'0"x4'0"<br />

3'0"x4'0"<br />

4'6"x4'6"<br />

4'6"x4'6"<br />

3'0"x4'6"<br />

3'0"x4'6"<br />

4'6"x4'6"<br />

4'6"x4'6"<br />

Fire Window<br />

Frame<br />

•<br />

•<br />

13'2"x11'7"<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

4'6"x4'6"<br />

(1) When glzing is used instead of panels in transoms and side lights, the maximum permitted rating is 1¹⁄₂ hour.<br />

(2) Equivalent metric dimensions in millimeters can be obtained by multiplying number of feet by 304.8.<br />

(3) Material thickness may vary for some approved products.<br />

(4) Maximum dimensions per segment. May be in the same plane or projected.<br />

HMMA Hollow Metal Frames<br />

The widest variety of frame profiles are available from NAAMM HMMA members. A sampling of profile configurations<br />

is shown below:<br />

Profile Variations<br />

HMMA members furnish many combinations of features to meet special design considerations, functions and applications.<br />

For all the details, contact any HMMA member listed on the back.

HMMA Frame Construction and Details<br />

7<br />

Typical Frame Assembly<br />

Continuously Welded<br />

Corner Joints<br />

Saw Mitered<br />

Punch Mitered<br />

Face Welded<br />

Corner Joint<br />

JAMB TABS<br />

STD. CLOSER<br />

REINFORCEMENT<br />

(IF CLOSER USED)<br />

HINGE JAMB<br />

STRIKE JAMB<br />

Cut-off Stops<br />

HINGE CUTOUT &<br />

REINFORCEMENT<br />

Common Jamb Anchors<br />

STRIKE CUTOUT &<br />

REINFORCEMENT<br />

90 deg.<br />

closed end<br />

(PERFORATED OR<br />

CORRUGATED STRAP)<br />

SPREADER<br />

Strap & Stirrup<br />

(masonry)<br />

T-Strap<br />

(masonry)<br />

Wire Loop<br />

(masonry)<br />

STANDARD FLOOR ANCHOR<br />

45 deg.<br />

closed end<br />

Wood Stud Wood Stud Steel Stud<br />

(Zee)<br />

Field Assembled Drywall Frame<br />

A<br />

CORNER<br />

SLOTS<br />

TO FACILITATE HANDLING<br />

AND/OR SHIPPING, LARGE<br />

FRAMES ARE PREPARED IN<br />

THE SHOP FOR FIELD SPLICING<br />

B<br />

KEY ELEVATION<br />

TABS<br />

PLASTIC<br />

PLUG<br />

COMPRESSION LUG<br />

FOR ALIGNMENT OF FRAME<br />

OTHER TYPES OF SIMILAR DEVICES<br />

ARE USED FOR THIS PURPOSE<br />

BY VARIOUS MANUFACTURES<br />

A<br />

B<br />

ANCHOR AT FLOOR<br />

SCREWED TO WALL FRAMING<br />

MEMBER<br />

HEAD TABS INTO JAMB SLOTS<br />

REPRESENTATIVE<br />

CORNER DETAILS<br />

OTHER METHODS ALSO USED --<br />

SYSTEMS VARY WITH MANUFACTURE<br />

JAMB TABS INTO<br />

HEAD SLOTS

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

)<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

8<br />

HMMA Hardware Preparation and Locations<br />

Butt Hinge<br />

Mortise Lock<br />

Cylindrical Lock<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

)<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) ) )<br />

Strike in Frame<br />

Recommended Hardware Locations<br />

Frame head rabbet<br />

5 in.<br />

(127 mm)<br />

Hinge<br />

Mortar Guard<br />

Equal<br />

Hinge<br />

Equal<br />

c<br />

of deadlock cylinder,<br />

push plate, and hospital<br />

arm pull (vertical type)<br />

c of roller latch and<br />

hospital push-pull<br />

c<br />

of door pull grip<br />

and push-pull bar<br />

c<br />

of knob on lock or<br />

latch and cross bar<br />

45 in.<br />

(1143 mm)<br />

46 in.<br />

(1168 mm)<br />

42 in.<br />

(1066 mm)<br />

Floor<br />

10 in.<br />

(254 mm)<br />

Hinge<br />

38 in.<br />

(965 mm)

HMMA Manufacturing Tolerances<br />

9<br />

Manufacturing tolerances shall be maintained within the following limits:<br />

1. Frames for single door or pair of doors;<br />

a. Width, measured between rabbets at the head:<br />

nominal opening width +1/16 in. (+1.5mm),<br />

-1/32 in. (-0.8mm).<br />

b. Height (total lenght of jamb rabbet):<br />

nominal opening height +1/16 in. (+1.5mm),<br />

-1/32 in. (-0.8mm).<br />

2. Doors:<br />

a. Width +/- 3/64 in. (1.2mm)<br />

b. Height +/- 3/64 in. (1.2mm)<br />

c. Thickness +/- 1/16 in. (1.5mm)<br />

3. Hardware:<br />

a. Cutout dimension +0.015 in., -0"<br />

b. Location +/- 1/32 in. (0.8mm)<br />

FRAME DEPTH<br />

+/- 1/16 IN. (1.5MM)<br />

THROAT OPENING<br />

+/- 3/32 IN. (2.4MM)<br />

FACE<br />

+/- 1/32 IN. (0.8MM)<br />

DOOR, GLASS OR<br />

PANEL LOCATION<br />

RABBET<br />

+/- 1/32 IN. (0.8MM)<br />

STOP<br />

+/- 1/32 IN. (0.8MM)<br />

Storage<br />

Installation<br />

Tolerances<br />

The contractor responsible for<br />

installation shall ensure that;<br />

1. Wraps or covers from<br />

doors and frames are<br />

removed upon delivery.<br />

90°<br />

SQUARENESS; MEASURED AT<br />

RABBET ON A LINE FROM JAMB<br />

PERPENDICULAR TO FRAME HEAD.<br />

2. Any scratches or<br />

disfigurements caused<br />

in shipping or handling<br />

are promptly cleaned<br />

and touched up with a<br />

rust-inhibitive primer.<br />

WOOD<br />

PLANKING<br />

HEAD<br />

MAXIMUM TOLERANCE<br />

1/16 IN. (1.5MM)<br />

3. Materials are properly on<br />

planks or dunnage in a dry<br />

location. Doors shall be stored in<br />

a verticle position and spaced<br />

by blocking.<br />

4. Materials shall be covered to<br />

protect them from damage,<br />

but in such a manor as to<br />

permit air circulation.<br />

PROFILE MAY VARY<br />

AS A FUNCTIONAL<br />

DESIGN<br />

HINGE OR<br />

STRIKE JAMB<br />

PLUMBNESS; MEASURED AT<br />

JAMBS ON A PERPENDICULAR<br />

LINE FROM THE HEAD TO THE<br />

FLOOR.<br />

ALIGNMENT; MEASURED AT<br />

JAMBS ON A HORIZONTAL<br />

LINE PARALLEL TO THE PLANE<br />

OF THE FACE.<br />

WOOD<br />

PLANKING<br />

90°<br />

TWIST; MEASURED AT OPPOSITE FACE<br />

CORNERS OF JAMBS ON PARALLEL<br />

LINES, PERPENDICULAR TO THE PLANE<br />

OF THE DOOR RABBET.

The Hollow Metal Manual<br />

The Hollow Metal Manual is presented in 14 separate, saddle-stitched<br />

sections in an attractive three-ring binder. The Manual provides design<br />

professionals the most current information on manufacturing, door and<br />

frame designs and details, hardware preparation and location, installation<br />

and storage, fire-rated applications, common terms, plus the<br />

guide specifications.<br />

The Hollow Metal Manufacturers Association (HMMA) Division of<br />

NAAMM, the National Association of Architectural Metal Manufacturers,<br />

publishes the Hollow Metal Manual to aid building design<br />

professionals in specifying hollow metal.<br />

The HMMA guide specifications cover a broad range of door and<br />

frame applications. HMMA 860 addresses doors and frames for light<br />

traffic areas. HMMA 861 covers doors and frames appropriate for use<br />

in higher traffic, commercial applications. HMMA 862 details doors<br />

and frames for commercial security applications; HMMA 863 covers<br />

detention security doors and frames. HMMA 865 is a guide for<br />

swinging sound control doors and frames. HMMA 866 covers stainless<br />

steel hollow metal doors and frames. HMMA 867 covers hollow metal<br />

doors and frames with laminated cores. HMMA members are ready to<br />

fill all your door and frame needs.<br />

The Hollow Metal Manual is also available in downloadable form and<br />

on CD. Visit the Hollow Metal Manufacturers Association web site at<br />

www.hollowmetal.org.<br />

Hollow Metal Manufacturers<br />

Association<br />

a Division of<br />

NAAMM<br />

8 S. Michigan Ave.• Suite 1000<br />

Chicago, IL 60603<br />

312/332-0405<br />

FAX: 312/332-0706<br />

www.hollowmetal.org