MachLine the perfect solution for your machine tools

MachLine: Machine Tools - NTN Bearing

MachLine: Machine Tools - NTN Bearing

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Preload: parameters<br />

to take into account<br />

Preload levels<br />

SNR has defined 3 preload levels which correspond<br />

to a level of contact pressure suitable <strong>for</strong> operating<br />

conditions:<br />

- Light preload (code 7):<br />

High-speed, light load applications.<br />

- Medium preload (code 8):<br />

Best balance between speed and load.<br />

- Heavy preload (code 9):<br />

Large load, reduced speed applications.<br />

- SNR can supply specific preloads on request<br />

(code X) to meet spindle operation optimization<br />

requirements.<br />

Should a specific preload be required, it can be<br />

achieved using bearings preloaded as standard<br />

assembled with different length spacers.<br />

The following <strong>for</strong>mula is used to calculate <strong>the</strong> space<br />

required between two spacers to alter <strong>the</strong> bearing<br />

assembly preload:<br />

2/3 2/3<br />

a = 2K(Pr i – Pr S )<br />

a: difference in length between <strong>the</strong> 2 spacers (µm)<br />

K: deflection constant (see page 44)<br />

Pr i : initial preload (daN)<br />

Pr s : preload required (daN)<br />

See also page 15, axial deflection<br />

of an angular contact ball bearing.<br />

Factors influencing preload<br />

The following factors can influence <strong>the</strong> preload<br />

value:<br />

- assembly interference (fits),<br />

- rotation speed,<br />

- temperature, possibly associated with shaft and<br />

housing materials,<br />

- geometry of <strong>the</strong> surrounding parts.<br />

Make sure <strong>the</strong>se parameters are fully taken into<br />

account when a spindle is designed. Contact<br />

SNR's design office <strong>for</strong> any fur<strong>the</strong>r in<strong>for</strong>mation.<br />

They are always prepared to share <strong>the</strong>ir expertise in<br />

this area.<br />

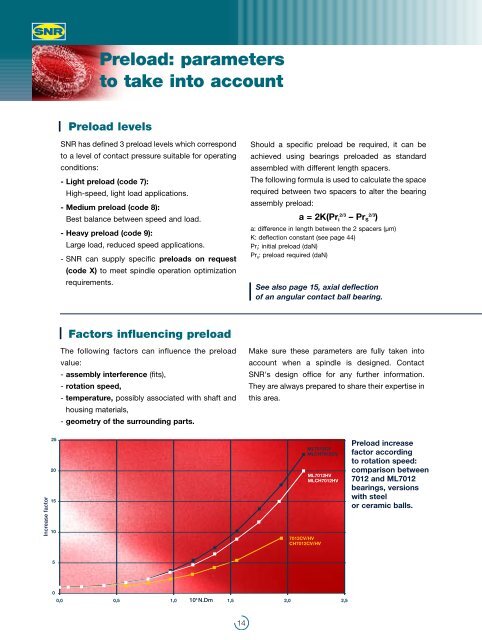

Increase factor<br />

25<br />

20<br />

15<br />

10<br />

7012CV/HV<br />

CH7012CV/HV<br />

ML7012CV<br />

MLCH7012CV<br />

ML7012HV<br />

MLCH7012HV<br />

Preload increase<br />

factor according<br />

to rotation speed:<br />

comparison between<br />

7012 and ML7012<br />

bearings, versions<br />

with steel<br />

or ceramic balls.<br />

5<br />

0<br />

0,0 0,5 1,0 10 6 N.Dm 1,5 2,0 2,5<br />

14