STRAND

01 - wire r ope & strand - Bullivants

01 - wire r ope & strand - Bullivants

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

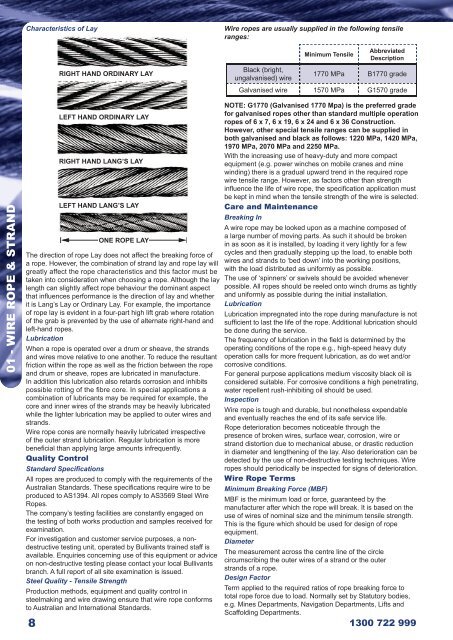

Characteristics of Lay<br />

RIGHT HAND ORDINARY LAY<br />

Wire ropes are usually supplied in the following tensile<br />

ranges:<br />

Black (bright,<br />

ungalvanised) wire<br />

Minimum Tensile<br />

Abbreviated<br />

Description<br />

1770 MPa B1770 grade<br />

Galvanised wire 1570 MPa G1570 grade<br />

01 - WIRE ROPE & <strong>STRAND</strong><br />

8<br />

LEFT HAND ORDINARY LAY<br />

RIGHT HAND LANG’S LAY<br />

LEFT HAND LANG’S LAY<br />

ONE ROPE LAY<br />

The direction of rope Lay does not affect the breaking force of<br />

a rope. However, the combination of strand lay and rope lay will<br />

greatly affect the rope characteristics and this factor must be<br />

taken into consideration when choosing a rope. Although the lay<br />

length can slightly affect rope behaviour the dominant aspect<br />

that infl uences performance is the direction of lay and whether<br />

it is Lang’s Lay or Ordinary Lay. For example, the importance<br />

of rope lay is evident in a four-part high lift grab where rotation<br />

of the grab is prevented by the use of alternate right-hand and<br />

left-hand ropes.<br />

Lubrication<br />

When a rope is operated over a drum or sheave, the strands<br />

and wires move relative to one another. To reduce the resultant<br />

friction within the rope as well as the friction between the rope<br />

and drum or sheave, ropes are lubricated in manufacture.<br />

In addition this lubrication also retards corrosion and inhibits<br />

possible rotting of the fi bre core. In special applications a<br />

combination of lubricants may be required for example, the<br />

core and inner wires of the strands may be heavily lubricated<br />

while the lighter lubrication may be applied to outer wires and<br />

strands.<br />

Wire rope cores are normally heavily lubricated irrespective<br />

of the outer strand lubrication. Regular lubrication is more<br />

benefi cial than applying large amounts infrequently.<br />

Quality Control<br />

Standard Specifications<br />

All ropes are produced to comply with the requirements of the<br />

Australian Standards. These specifi cations require wire to be<br />

produced to AS1394. All ropes comply to AS3569 Steel Wire<br />

Ropes.<br />

The company’s testing facilities are constantly engaged on<br />

the testing of both works production and samples received for<br />

examination.<br />

For investigation and customer service purposes, a nondestructive<br />

testing unit, operated by Bullivants trained staff is<br />

available. Enquiries concerning use of this equipment or advice<br />

on non-destructive testing please contact your local Bullivants<br />

branch. A full report of all site examination is issued.<br />

Steel Quality - Tensile Strength<br />

Production methods, equipment and quality control in<br />

steelmaking and wire drawing ensure that wire rope conforms<br />

to Australian and International Standards.<br />

NOTE: G1770 (Galvanised 1770 Mpa) is the preferred grade<br />

for galvanised ropes other than standard multiple operation<br />

ropes of 6 x 7, 6 x 19, 6 x 24 and 6 x 36 Construction.<br />

However, other special tensile ranges can be supplied in<br />

both galvanised and black as follows: 1220 MPa, 1420 MPa,<br />

1970 MPa, 2070 MPa and 2250 MPa.<br />

With the increasing use of heavy-duty and more compact<br />

equipment (e.g. power winches on mobile cranes and mine<br />

winding) there is a gradual upward trend in the required rope<br />

wire tensile range. However, as factors other than strength<br />

influence the life of wire rope, the specifi cation application must<br />

be kept in mind when the tensile strength of the wire is selected.<br />

Care and Maintenance<br />

Breaking In<br />

A wire rope may be looked upon as a machine composed of<br />

a large number of moving parts. As such it should be broken<br />

in as soon as it is installed, by loading it very lightly for a few<br />

cycles and then gradually stepping up the load, to enable both<br />

wires and strands to ‘bed down’ into the working positions,<br />

with the load distributed as uniformly as possible.<br />

The use of ‘spinners’ or swivels should be avoided whenever<br />

possible. All ropes should be reeled onto winch drums as tightly<br />

and uniformly as possible during the initial installation.<br />

Lubrication<br />

Lubrication impregnated into the rope during manufacture is not<br />

sufficient to last the life of the rope. Additional lubrication should<br />

be done during the service.<br />

The frequency of lubrication in the field is determined by the<br />

operating conditions of the rope e.g., high-speed heavy duty<br />

operation calls for more frequent lubrication, as do wet and/or<br />

corrosive conditions.<br />

For general purpose applications medium viscosity black oil is<br />

considered suitable. For corrosive conditions a high penetrating,<br />

water repellent rush-inhibiting oil should be used.<br />

Inspection<br />

Wire rope is tough and durable, but nonetheless expendable<br />

and eventually reaches the end of its safe service life.<br />

Rope deterioration becomes noticeable through the<br />

presence of broken wires, surface wear, corrosion, wire or<br />

strand distortion due to mechanical abuse, or drastic reduction<br />

in diameter and lengthening of the lay. Also deterioration can be<br />

detected by the use of non-destructive testing techniques. Wire<br />

ropes should periodically be inspected for signs of deterioration.<br />

Wire Rope Terms<br />

Minimum Breaking Force (MBF)<br />

MBF is the minimum load or force, guaranteed by the<br />

manufacturer after which the rope will break. It is based on the<br />

use of wires of nominal size and the minimum tensile strength.<br />

This is the figure which should be used for design of rope<br />

equipment.<br />

Diameter<br />

The measurement across the centre line of the circle<br />

circumscribing the outer wires of a strand or the outer<br />

strands of a rope.<br />

Design Factor<br />

Term applied to the required ratios of rope breaking force to<br />

total rope force due to load. Normally set by Statutory bodies,<br />

e.g. Mines Departments, Navigation Departments, Lifts and<br />

Scaffolding Departments.<br />

1300 722 999