MEATing POINT Magazine: #03/ 2015

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

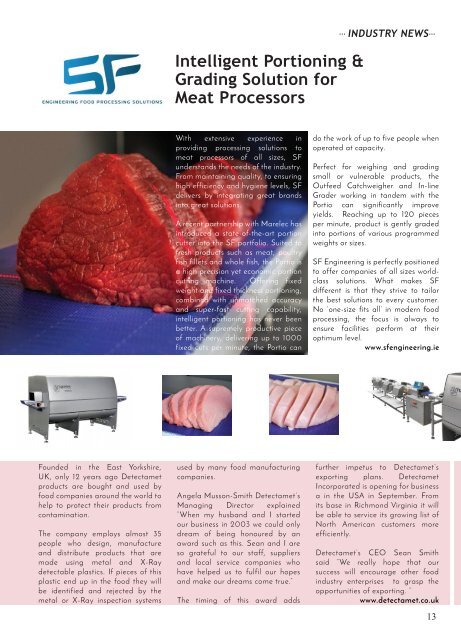

Intelligent Portioning &<br />

Grading Solution for<br />

Meat Processors<br />

... INDUSTRY NEWS...<br />

With extensive experience in<br />

providing processing solutions to<br />

meat processors of all sizes, SF<br />

understands the needs of the industry.<br />

From maintaining quality, to ensuring<br />

high efficiency and hygiene levels, SF<br />

delivers by integrating great brands<br />

into great solutions.<br />

A recent partnership with Marelec has<br />

introduced a state-of-the-art portion<br />

cutter into the SF portfolio. Suited to<br />

fresh products such as meat, poultry<br />

fish fillets and whole fish, the Portio is<br />

a high precision yet economic portion<br />

cutting machine. Offering fixed<br />

weight and fixed thickness portioning,<br />

combined with unmatched accuracy<br />

and super-fast cutting capability,<br />

intelligent portioning has never been<br />

better. A supremely productive piece<br />

of machinery, delivering up to 1000<br />

fixed cuts per minute, the Portio can<br />

do the work of up to five people when<br />

operated at capacity.<br />

Perfect for weighing and grading<br />

small or vulnerable products, the<br />

Outfeed Catchweigher and In-line<br />

Grader working in tandem with the<br />

Portio can significantly improve<br />

yields. Reaching up to 120 pieces<br />

per minute, product is gently graded<br />

into portions of various programmed<br />

weights or sizes.<br />

SF Engineering is perfectly positioned<br />

to offer companies of all sizes worldclass<br />

solutions. What makes SF<br />

different is that they strive to tailor<br />

the best solutions to every customer.<br />

No ‘one-size fits all’ in modern food<br />

processing, the focus is always to<br />

ensure facilities perform at their<br />

optimum level.<br />

www.sfengineering.ie<br />

Founded in the East Yorkshire,<br />

UK, only 12 years ago Detectamet<br />

products are bought and used by<br />

food companies around the world to<br />

help to protect their products from<br />

contamination.<br />

The company employs almost 35<br />

people who design, manufacture<br />

and distribute products that are<br />

made using metal and X-Ray<br />

detectable plastics. If pieces of this<br />

plastic end up in the food they will<br />

be identified and rejected by the<br />

metal or X-Ray inspection systems<br />

used by many food manufacturing<br />

companies.<br />

Angela Musson-Smith Detectamet’s<br />

Managing Director explained<br />

“When my husband and I started<br />

our business in 2003 we could only<br />

dream of being honoured by an<br />

award such as this. Sean and I are<br />

so grateful to our staff, suppliers<br />

and local service companies who<br />

have helped us to fulfil our hopes<br />

and make our dreams come true.”<br />

The timing of this award adds<br />

further impetus to Detectamet’s<br />

exporting plans. Detectamet<br />

Incorporated is opening for business<br />

a in the USA in September. From<br />

its base in Richmond Virginia it will<br />

be able to service its growing list of<br />

North American customers more<br />

efficiently.<br />

Detectamet’s CEO Sean Smith<br />

said “We really hope that our<br />

success will encourage other food<br />

industry enterprises to grasp the<br />

opportunities of exporting. “<br />

www.detectamet.co.uk<br />

13