NOSHOK Sanitary Pressure Gauge Catalog - DFS Gauges

NOSHOK Sanitary Pressure Gauge Catalog - DFS Gauges

NOSHOK Sanitary Pressure Gauge Catalog - DFS Gauges

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

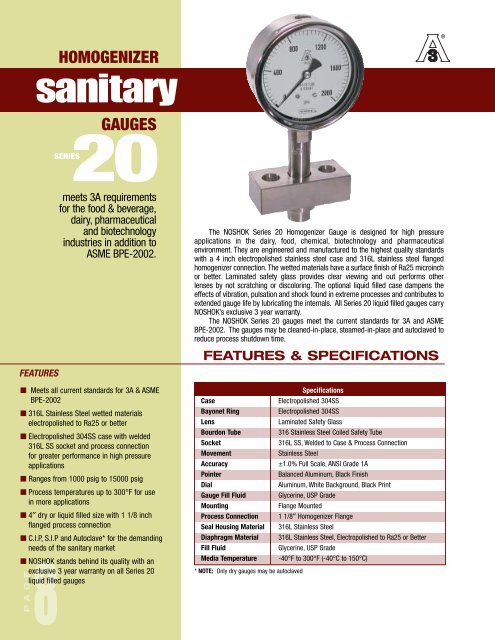

HOMOGENIZER<br />

sanitary<br />

FEATURES<br />

P A G E<br />

GAUGES<br />

20<br />

SERIES<br />

meets 3A requirements<br />

for the food & beverage,<br />

dairy, pharmaceutical<br />

and biotechnology<br />

industries in addition to<br />

ASME BPE-2002.<br />

■ Meets all current standards for 3A & ASME<br />

BPE-2002<br />

■ 316L Stainless Steel wetted materials<br />

electropolished to Ra25 or better<br />

■ Electropolished 304SS case with welded<br />

316L SS socket and process connection<br />

for greater performance in high pressure<br />

applications<br />

■ Ranges from 1000 psig to 15000 psig<br />

■ Process temperatures up to 300°F for use<br />

in more applications<br />

■ 4″ dry or liquid filled size with 1 1/8 inch<br />

flanged process connection<br />

■ C.I.P, S.I.P and Autoclave* for the demanding<br />

needs of the sanitary market<br />

■ <strong>NOSHOK</strong> stands behind its quality with an<br />

exclusive 83 year warranty on all Series 20<br />

liquid filled gauges<br />

The <strong>NOSHOK</strong> Series 20 Homogenizer <strong>Gauge</strong> is designed for high pressure<br />

applications in the dairy, food, chemical, biotechnology and pharmaceutical<br />

environment. They are engineered and manufactured to the highest quality standards<br />

with a 4 inch electropolished stainless steel case and 316L stainless steel flanged<br />

homogenizer connection. The wetted materials have a surface finish of Ra25 microinch<br />

or better. Laminated safety glass provides clear viewing and out performs other<br />

lenses by not scratching or discoloring. The optional liquid filled case dampens the<br />

effects of vibration, pulsation and shock found in extreme processes and contributes to<br />

extended gauge life by lubricating the internals. All Series 20 liquid filled gauges carry<br />

<strong>NOSHOK</strong>’s exclusive 3 year warranty.<br />

The <strong>NOSHOK</strong> Series 20 gauges meet the current standards for 3A and ASME<br />

BPE-2002. The gauges may be cleaned-in-place, steamed-in-place and autoclaved to<br />

reduce process shutdown time.<br />

FEATURES & SPECIFICATIONS<br />

Case<br />

Bayonet Ring<br />

Lens<br />

Bourdon Tube<br />

Socket<br />

Movement<br />

Accuracy<br />

Pointer<br />

Dial<br />

<strong>Gauge</strong> Fill Fluid<br />

Mounting<br />

Process Connection<br />

Seal Housing Material<br />

Diaphragm Material<br />

Fill Fluid<br />

Media Temperature<br />

* NOTE: Only dry gauges may be autoclaved<br />

Specifications<br />

Electropolished 304SS<br />

Electropolished 304SS<br />

Laminated Safety Glass<br />

316 Stainless Steel Coiled Safety Tube<br />

316L SS, Welded to Case & Process Connection<br />

Stainless Steel<br />

±1.0% Full Scale, ANSI Grade 1A<br />

Balanced Aluminum, Black Finish<br />

Aluminum, White Background, Black Print<br />

Glycerine, USP Grade<br />

Flange Mounted<br />

1 1/8″ Homogenizer Flange<br />

316L Stainless Steel<br />

316L Stainless Steel, Electropolished to Ra25 or Better<br />

Glycerine, USP Grade<br />

-40°F to 300°F (-40°C to 150°C)