Resistance

RM - Maschinenfabrik Niehoff GmbH & Co. KG

RM - Maschinenfabrik Niehoff GmbH & Co. KG

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

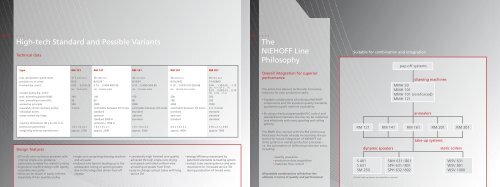

High-tech Standard and Possible Variants<br />

Technical data<br />

type<br />

max. production speed (m/s):<br />

possible no. of wires:<br />

finished dia. (mm):<br />

contact pulley dia. (mm):<br />

max. annealing power (kW):<br />

max. annealing current (A):<br />

annealing principle:<br />

separately driven auxiliary pulley:<br />

individual drives:<br />

water-cooled slip rings:<br />

machine dimensions (W x D x H) in m:<br />

(without transformer)<br />

weight (kg without transformer):<br />

RM 121<br />

31.5 (6201 fpm)<br />

8/16<br />

0.05 ... 0.25/0.25<br />

(44 ... 30/30 AWG)<br />

140<br />

30<br />

500<br />

3-zone<br />

1.3 x 1.0 x 2.1<br />

approx. 2200<br />

RM 141<br />

36 (7087 fpm)<br />

8/16/24<br />

0.10 ... 0.40/0.40/0.40<br />

(38 ... 26/26/26 AWG)<br />

140<br />

60<br />

2000<br />

switchable between 2/3 zones<br />

standard<br />

optional<br />

standard 2000 A<br />

optional < 1500 A<br />

1.6 x 1.0 x 2.1<br />

approx. 2500<br />

RM 161<br />

40 (7874 fpm)<br />

8/16/24<br />

0.10 ... 0.60/0.50/0.40<br />

(38 ... 22.5/24/26 AWG)<br />

160<br />

80<br />

2000<br />

switchable between 2/3 zones<br />

standard<br />

optional<br />

standard<br />

1.6 x 1.0 x 2.3<br />

approx. 3000<br />

Design features<br />

RM 201<br />

40 (7874 fpm)<br />

8/16/24/32<br />

0.10 ...1.05/0.72/0.55/0.48<br />

(38 ... 18/21/23.5/24 ½ AWG)<br />

200<br />

180<br />

2000<br />

switchable between 2/3 zones<br />

standard<br />

optional<br />

standard<br />

2.0 x 1.4 x 2.3<br />

approx. 4600<br />

RM 301<br />

40 (7874 fpm)<br />

7/14/28/42<br />

0.40 ... 1.35/0.35 ... 1.15<br />

(26 ... 15 ½ / 27 ½ ... 17)<br />

0.25 ... 0.90/0.25 ... 0.70<br />

(30 ... 19/30 ... 21 ½)<br />

300<br />

350<br />

7000<br />

2 or 3 zones<br />

standard<br />

standard<br />

standard<br />

3.55 x 2.1 x 3.04<br />

approx. 7000<br />

The<br />

NIEHOFF Line<br />

Philosophy<br />

Overall integration for superior<br />

performance<br />

The entire line delivers technically innovative<br />

solutions for your production tasks:<br />

Capable combinations of individual NIEHOFF<br />

components and the excellent quality standards<br />

guarantee superb machine availability.<br />

By using a freely programmable PLC control and<br />

standardized interfaces, the line can be combined<br />

very effectively with many spooling and coiling<br />

systems.<br />

The MMH line concept with the RM Continuous<br />

<strong>Resistance</strong> Annealer already incorporates the potential<br />

for future integration of NIEHOFF machine<br />

systems in overall production processes –<br />

i.e. the automation of different production areas,<br />

including:<br />

Suitable for combination and integration<br />

dynamic spoolers<br />

pay-off systems<br />

drawing machines<br />

MMH 50<br />

MMH 101<br />

MMH 101 (reinforced)<br />

MMH 121<br />

annealers<br />

RM 121 RM 141 RM 161 RM 201<br />

take-up systems<br />

static coilers<br />

RM 301<br />

DC multi-wire resistance annealer with<br />

internal single-wire guidance,<br />

particularly suitable for coated Cu wires<br />

ergonomic machine design with openly<br />

accessible wire paths<br />

wires can be drawn in easily with the<br />

separately driven auxiliary pulley<br />

single unit comprising drawing machine<br />

and annealer<br />

reduced wire tension leading up to the<br />

subsequent coiling or spooling system<br />

due to the integrated driven haul-off<br />

capstan<br />

consistently high finished wire quality<br />

achieved through single-wire drying<br />

and speed-controlled uniform wire<br />

annealing at speeds from 0 m/s<br />

easy-to-change contact tubes with long<br />

service life<br />

energy efficiency maximized by<br />

patented selectable re-heating system<br />

contact tube cleaning device and wire<br />

movement for increased service life<br />

during production of tinned wires<br />

quality assurance<br />

production data acquisition<br />

materials flow control<br />

All possible combinations will deliver the<br />

ultimate in terms of quality and performance!<br />

S 401<br />

S 631<br />

SM 250<br />

(Further take-up systems are available on request)<br />

SNH 631/801<br />

SPH 631/801<br />

SPH 632 / 802<br />

WSV 631<br />

WSV 801<br />

WSV 1000