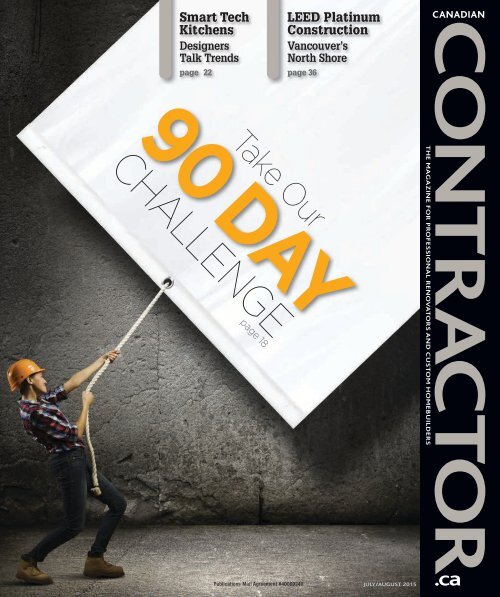

Canadian Contractor - July-August 2015

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Smart Tech<br />

Kitchens<br />

Designers<br />

Talk Trends<br />

page 22<br />

LEED Platinum<br />

Construction<br />

Vancouver’s<br />

North Shore<br />

page 36<br />

CANADIAN<br />

Take Our<br />

90 DAY<br />

CHALLENGE<br />

page 18<br />

THE MAGAZINE FOR PROFESSIONAL RENOVATORS AND CUSTOM HOMEBUILDERS<br />

Publications Mail Agreement #40069240 JULY/AUGUST <strong>2015</strong><br />

.ca

ARE YOU CHOOSING THE<br />

BEST BUILDING SOLUTION?<br />

Featured Product: HYDROFOAM ®<br />

The Integrated Series<br />

from NUDURA builds value<br />

into your next project.<br />

The Integrated series from NUDURA combines building<br />

envelope products that work in conjunction with our line of<br />

Insulated Concrete Forms or independently to provide maximum<br />

energy efficiency. Our Integrated Series offers Ceiling & Floor<br />

insulation, HYDROFOAM ® , and our unique RetroFit system for<br />

existing buildings.<br />

integrated<br />

series<br />

><<br />

®<br />

Learn how the Integrated Series can provide the best solution for your next project:<br />

www.nudura.com/integratedseries | 1-866-468-6299<br />

Follow us on:

CONTENTS<br />

18 Cover Story<br />

Take Our<br />

features<br />

COVER STORY<br />

The 90 Day Profitability<br />

Challenge 18<br />

Do you know how much money you are<br />

going to make in the next 90 days? Mike Draper,<br />

Renovantage, shows you how to figure it out.<br />

90 DAY<br />

CHALLENGE<br />

Smart Tech Kitchens 22<br />

We interview award-winning designers<br />

on what makes an ultra-modern<br />

upmarket kitchen sing.<br />

Good Works<br />

from Saint Gobain 30<br />

The building products giant, celebrating<br />

350 years in business, makes a serious<br />

commitment to turning disadvantaged<br />

youth into contractors.<br />

Helping Clients Find<br />

the Money 34<br />

Calgary builder PLANiT partners up with<br />

“merchant direct” credit company Financeit<br />

to help their customers fund renovations.<br />

Professional Painting in Calgary 42<br />

A profile of The Urban Painter, an<br />

entrepreneurial painting firm that is<br />

riding high in The Stampede City.<br />

Saint Gobain<br />

30<br />

350 years<br />

42<br />

Urban<br />

Painter<br />

www.canadiancontractor.ca <strong>July</strong>/<strong>August</strong> <strong>2015</strong> 3

CONTENTS<br />

Handy<br />

Man<br />

10<br />

Maxwell’s<br />

Picks<br />

56<br />

departments<br />

Online 6<br />

A look at some of the great<br />

stuff we have online at<br />

canadiancontractor.ca.<br />

Editorials 8<br />

Does your contracting business have<br />

a brand name? Rob and Steve talk<br />

about why it matters.<br />

Site Notes 10<br />

An interview with Wayne Jackson,<br />

a one-man handyman dynamo in<br />

Amherstburg, Ontario.<br />

Voices 12<br />

A sample of some of the online<br />

comments from our 16,500 contractor<br />

e-news subscribers.<br />

Maxwell’s Stuff We Like 49<br />

How to create incredibly sharp<br />

hand tools in two minutes or less.<br />

Enviroslate roofing. DeWalt<br />

miter saw.<br />

What Would You Do? 58<br />

Tell us how you would handle this<br />

sticky business situation. If we<br />

pick your answer, you will win a<br />

DeWalt cordless framing nailer.<br />

49<br />

Hone Run<br />

58<br />

What Would<br />

You Do?<br />

4 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

Introducing Fiberon Symmetry Railing.<br />

Fiberon Symmetry Railing has a unique two-piece top rail design, featuring an<br />

aluminum channel reinforcement and versatile hidden bracket system. It’s easy<br />

to install, provides application flexibility and is extremely sturdy. Symmetry Railing<br />

comes in a beautiful matte white finish with a spanning capability up to 12 feet. So you<br />

can finally give your customers the look they’ve been asking for. Learn more about<br />

the benefits of Symmetry Railing at fiberondecking.com.

ONLINE<br />

Visit us online<br />

CANADIAN<br />

CONTRACTOR .ca<br />

VIDEO<br />

A WAY TO PUT ALL YOUR CONTRACT PAPERWORK IN YOUR POCKET<br />

RENOMii is pretty cool. In a nutshell, it’s a way to upload all your projects’ paperwork so<br />

that all those hundreds of pieces of job-related information don’t get lost. Your client can<br />

log in and access them, you can access them. Your contracts, change orders and other<br />

critical documents are all on your mobile device, or wherever you want them.<br />

Type “RENOMii” in the search bar at canadiancontractor.ca to find this video easily<br />

VIDEO<br />

MAKING YOUR OWN MOULDINGS ONSITE USING A ROUTER<br />

In under 3 minutes, our tools editor Steve Maxwell shows you how you can can do custom<br />

handrails, door and window trim, crown moulding, wainscoting – endless types of "millwork"<br />

– using a simple router and some attachments. As Steve says, this type of router usage by<br />

contractors, onsite, is not "typical." But it can make you money.<br />

Type “Router” in the search bar at canadiancontractor.ca to find this video easily<br />

SALARY SURVEY<br />

PRICE OF MATERIALS ISN’T THE BIG DEAL WE ALL THINK IT IS<br />

Well, most of us kind of “knew” this, but now the proof is in. <strong>Contractor</strong>s don’t rank the price of<br />

materials, supplies and tools as highly as anxious lumberyards and big box stores often think<br />

they do. Only 28 per cent of the contractors we surveyed, in our annual <strong>Canadian</strong> <strong>Contractor</strong> Salary<br />

Survey, told us that “Price” was the most important factor when they shopped for an item.<br />

Type “Salary Survey” in the search bar at canadiancontractor.ca to find this video easily<br />

CANADIAN<br />

CONTRACTOR<br />

BUILD | GROW | PROFIT<br />

.ca<br />

Volume 16, Number 4<br />

<strong>July</strong>/<strong>August</strong> <strong>2015</strong><br />

canadiancontractor.ca | Tel: 416 442 5600 |<br />

80 Valleybrook Drive,<br />

North York, ON, M3B 2S9<br />

<strong>Canadian</strong> <strong>Contractor</strong>, established in 2000,<br />

is published 6 times a year by<br />

Annex Business Media.<br />

ISSN 1498-8941 (Print)<br />

ISSN 1929-6495 (Online)<br />

Editor<br />

Steve Payne<br />

spayne@canadiancontractor.ca<br />

Contributing Editors<br />

John Bleasby, John Caulfield, Mike Draper,<br />

Kim Laudrum, Steve Maxwell<br />

Art Director<br />

Mary Peligra<br />

mpeligra@annexnewcom.ca<br />

Publisher<br />

Rob Koci<br />

rkoci@canadiancontractor.ca<br />

Production Manager<br />

Gary White<br />

gwhite@annexnewcom.ca<br />

Circulation Manager<br />

Beata Olechnowicz<br />

bolechnowicz@annexnewcom.ca<br />

Mike Fredericks, President & CEO<br />

Annex Business Media<br />

Tim Dimopoulos, Vice President,<br />

Annex Business Media East<br />

Corinne Lynds, Editorial Director<br />

Subscriber Services<br />

To subscribe, renew your subscription or<br />

to change your address or information,<br />

contact us at 416 442 5600 x3547<br />

Subscription Rates: Canada $45.95 per<br />

year, Outside Canada $83.95US per year,<br />

Single Copy Canada $9.95.<br />

Privacy Notice<br />

From time to time we make our<br />

subscription list available to select<br />

companies and organizations whose<br />

product or service may be of interest<br />

to you. If you do not wish your contact<br />

information to be made available,<br />

please contact us via one of the<br />

following methods:<br />

Tel: 1-800-668-2374<br />

Fax: 416-442-2191<br />

Email Privacy Office:<br />

vmoore@annexnewcom.ca<br />

Mail:<br />

Privacy Office,<br />

80 Valleybrook Drive,<br />

North York, ON, M3B 2S9.<br />

Contents of this publication are<br />

protected by copyright and must<br />

not be reprinted in whole or in part<br />

without permission of the publisher.<br />

Publications Mail Agreement<br />

No. 40069240<br />

Canada<br />

We acknowledge the financial support<br />

of the Government of Canada through<br />

the Canada Periodical Fund of the<br />

Department of <strong>Canadian</strong> Heritage.<br />

6 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

Rob Hauser<br />

Hauser Home Hardware<br />

Building Centre<br />

Camrose, AB<br />

WE OFFER EVERY COMMODITY YOU CAN BUY –<br />

PLUS ONE THAT CAN ONLY BE EARNED: TRUST<br />

In contracting, there’s always elements you can’t control, from the price of commodities to the<br />

weather. But there’s one thing you can depend on: HH Pro <strong>Contractor</strong> Services. Because we’re<br />

business owners just like you, and we recognize that reliability is one of the world’s most<br />

valuable – and scarcest – resources. And we work hard to gain your trust the old-fashioned<br />

way: by earning it.<br />

homehardware.ca

EDITORIAL<br />

Voices<br />

”<br />

If you have no<br />

brand affiliations,<br />

your competition<br />

is real.<br />

”<br />

Rob Koci<br />

Publisher<br />

rkoci@canadiancontractor.ca<br />

WHY YOU NEED A BRAND NAME<br />

By Rob Koci<br />

The Holmes Referred <strong>Contractor</strong> Program went away last summer,<br />

though you can still see that logo on the side of renovators’ trucks.<br />

It doesn’t take long to apply to become a Baeumler Approved<br />

<strong>Contractor</strong> – just go to their website and fill out a form. If you join<br />

your local homebuilders’ association, the RenoMark brand is all<br />

yours. If online exposure is important to you, you can pay HomeStars<br />

or TrustedPros some money and get their logo on your vehicle, your<br />

website, or anywhere else you want to put it.<br />

The business of selling brand names to contractors and<br />

renovators has gone into overdrive. Our industry is in a brand-rush<br />

for at least three reasons:<br />

• Increased regulation is scaring the hell out of some<br />

independent contractors. They realize they must either get bigger<br />

to cover regulatory costs, do more cash work or die. Getting bigger<br />

means getting more work – and having a brand name appears to<br />

offer it.<br />

• Lack of skill in the face of today’s more educated homeowner is<br />

making some contractors very nervous indeed. They are looking for<br />

a brand to hide behind.<br />

• Reno horror stories are scaring the hell out of most homeowners<br />

and they are looking for a contractor with a brand they can trust.<br />

If you have no brand affiliations whatsoever, the competition<br />

you are facing from contractors with all those logos on their trucks<br />

is real. So what do you do? Here’s my sincere advice if you decide<br />

to go shopping for a brand:<br />

• Look very long term. Does the brand have sustainable value?<br />

Does it have any value at all?<br />

• “You get what you pay for” is most true in the world of brands.<br />

• Ask yourself if the brand name you are considering has a good<br />

chance of being exploited by contractors with no skill or scruples.<br />

If it does, don’t sign up.<br />

Paying someone a couple hundred bucks just to show their logo<br />

on your business card will do very little for you if there are clowns<br />

and con artists waving the same flag.<br />

8 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

EDITORIAL<br />

IN PRAISE OF NO-NAMES<br />

By Steve Payne<br />

When a bunch of squirrels invaded my family’s townhome last<br />

month (well, our attic), the condo management firm sent in one of<br />

the biggest North American brand names in pest control to deal<br />

with the situation.<br />

The friendly, reassuring franchisee who waddled up a ladder<br />

to our roof put a live-trap by the access hole in the fascia. The<br />

next day, he’d caught a squirrel, whereupon he took the trap<br />

down and sealed up the access hole with sheet metal. Never to<br />

contact me again.<br />

The whole thing took just 24 hours – to prove that he was<br />

totally incompetent and his company’s brand name didn’t<br />

mean squat.<br />

The squirrels who remained inside let us know all weekend<br />

that the clock was ticking on the stink they were going to emit<br />

when they died.<br />

I asked the property manager to send us a competent operator<br />

to fix the mess. Two young lads arrived, without logos, a one-off<br />

firm that was not a franchise. No brand name but their own.<br />

They first walked all the neighbouring townhouse roofs for<br />

20 minutes, trying to find out if there were other access points<br />

before they dealt with ours. Then one of them entered the attic to<br />

check things out – the brand name firm hadn’t even bothered.<br />

Only after about an hour of these inspections did they go<br />

about unscrewing the sheet metal from the original access hole.<br />

They then screwed on an exclusion door – a one-way funnel of<br />

wire – rather than a live trap. All the remaining squirrels exited<br />

on their own in the next few days.<br />

No brand name, no logo. Total expertise and attention to<br />

detail. Problem solved.<br />

<strong>Contractor</strong>s, you don’t need a purchased brand name if you<br />

operate like these pros.<br />

”<br />

No purchased<br />

brand name<br />

was necessary.<br />

”<br />

Steve Payne<br />

Editor<br />

spayne@canadiancontractor.ca<br />

Voices<br />

www.canadiancontractor.ca <strong>July</strong>/<strong>August</strong> <strong>2015</strong> 9

SITE NOTES<br />

Tips on Running a One-Man Handyman Operation<br />

An Interview with. . .<br />

Wayne Jackson, Wayne Jackson Handyman Services,<br />

Amherstburg, Ontario.<br />

Wayne Jackson is a<br />

throwback to another<br />

time. No puffed up titles<br />

for him! He’s happy<br />

to be what he is –<br />

a handyman.<br />

For the past 29<br />

years, Wayne has been<br />

building, renovating and repairing just about everything in the<br />

homes and gardens of his many loyal customers. Currently he’s<br />

based in Amherstburg, Ontario, in the extreme southwestern part<br />

of the province.<br />

Our Contributing Editor John Bleasby asks Wayne how he’s<br />

managed to turn something so simple into a good living.<br />

How long have you been handy?<br />

Since I was six. Anything my mother bought I tore apart, just<br />

to see what made it tick. I grew up on a farm and so I started<br />

working for a lot of the farmers, making things work.<br />

You market yourself as a handyman, pure and simple.<br />

No grand titles?<br />

I don’t want to step on anyone’s toes or hurt anyone else’s<br />

business. Plus, I want to cover as wide a spectrum as I can with<br />

small jobs. I don’t want to limit myself by saying I’m a contractor<br />

or any kind of specialist.<br />

Do you work solely on your own or do you have employees?<br />

Mostly on my own. I do my own plumbing, carpentry, and tiling,<br />

but I don’t touch anything electrical. I bring in specialty trades<br />

when I need them, but I get the client to hire them directly.<br />

You’ve recently moved to this new area. What are the challenges<br />

you’ve faced marketing to a new client base?<br />

I’m finding a lot of people here expect me to do the cash thing,<br />

which I don’t do. When the GST dropped from 7 per cent to 5 per<br />

cent, it wasn’t so bad. Now it’s the HST at 13 per cent, so the cash<br />

thing has started again.<br />

What would you say to someone starting up their<br />

own one-man operation?<br />

Put flyers everywhere: grocery stores and hardware stores.<br />

Get the word out as much as you can. Put your name on your<br />

vehicle. I have a red van with 5-inch letters on both sides saying<br />

“Wayne Jackson, Handyman” and my phone number. It’s not for<br />

my clients; I want neighbours five or six houses down to read<br />

my name and number. It’s a business card that I drive around<br />

in. Advertise in the local paper. Some people feel if you’re not<br />

in the local paper, you’re not in business. My wife had them<br />

create a heading for ‘Handyman’. I’m the only one in the section!<br />

I also have a website that brings in about 20-25 per cent of my<br />

inquiries. That’s been really good.<br />

Are you able to enjoy 12 months of work?<br />

I send out a mailing in the spring to promote outside work. In the<br />

fall I do another mailing for inside jobs, like bathrooms, vanities<br />

and so on. I ask customers to make lists of what they want done.<br />

It’s more cost-effective for them. It’s expensive to hire me to<br />

change a light bulb.<br />

What are your Red Flags with prospective customers?<br />

I can tell if it’s going to be a good relationship or if there’s going<br />

to be trouble. I run into some who want a ‘deal.’ People with<br />

money are often the worst. You give them a quote and they want<br />

you to knock 10 per cent off to get the job or even 10 per cent off<br />

at the end of the job! And people who say that Mike Holmes says<br />

to get three or more references and quotes, stuff like that. My<br />

answer is simple: ‘Hire Mike Holmes.’ If a customer is going to<br />

start a relationship like that, I’m a bit hesitant to get involved. I<br />

never drop my rates. I charge for my experience and the cost of<br />

running my business.<br />

Collections are not something many independent operators<br />

like to do. How do you manage that part?<br />

I ask for materials payments up front. And I get paid weekly for<br />

the work done to date, every Friday. I try to avoid problems right<br />

off. For example, I don’t pick colours for paints, but I choose the<br />

brand. The guy in the paint shop doesn’t really care; he’s not<br />

doing the job.<br />

How has being a handyman worked out for<br />

you financially?<br />

Everyone wants more, I guess. But the fact I’ve been in business<br />

for 29 years speaks for itself.<br />

10 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

corotechcoatings.ca<br />

©2014 Benjamin Moore & Co. All trademarks are registered trademarks of their respective owner.

VOICES<br />

CRAPPY CHINESE SHINGLES<br />

Alec Caldwell wrote an online post for us on June 17 called “Just What<br />

Our Industry Needed: Cheap, Crappy Chinese Shingles.” It detailed<br />

the appearance in Canada of thin, lightweight shingles that don’t<br />

meet CSA standards. And guess what? They don’t need to, at least<br />

for renovation applications. Only new homes require CSA-certified<br />

shingles. Time to close that loophole, we think. Here is a sampling of<br />

our online comments from contractors.<br />

“What is cheap now, ends up costing more…”<br />

Excellent article that shines a light on a growing problem in the <strong>Canadian</strong> construction<br />

industry. It’s not just shingles, however. Stucco and plaster materials that are not up to code are<br />

being used regularly here in Calgary by contractors who cheat innocent, unknowing customers.<br />

This usually results in cracking, water damage, and mould on the frame of the house. Another<br />

growing problem, at least here in Calgary, is windows made from cheap Chinese materials and<br />

hardware. Not only are the companies selling these windows destroying the market with their<br />

ridiculously cheap prices, I have my doubts about their certifications, as I have seen them first<br />

hand and they are an abomination. People need to remember that what is cheap now, ends up<br />

costing significantly more in the long run.<br />

Michael<br />

“Shingles falling in Milton, Ontario”<br />

I saw shingles falling off of townhouses in Milton, Ontario last February. I inspected them and<br />

found they are much thinner than the 25-year shingles from IKO. My roofing supplier told me<br />

they are from China. So beware of your shingles. I try to avoid anything Chinese made. I never<br />

frequent dollar stores. I make every attempt to investigate product origin. I do not support<br />

sellers or manufacturers that pass along Chinese material or product. It is time we closed<br />

the doors and started supporting Canada and the standards we need to stay safe. Punish<br />

manufactures and companies that move their businesses to China.<br />

Rey Talusa<br />

ASKING CUSTOMERS TO RATE YOU<br />

John Bleasby hired about 30 subtrades when building a house near<br />

Coldwater, Ontario – and noted in his online post that not one of them<br />

asked him, at any time, how happy he was with their work. This kickstarted<br />

a discussion on our site about how few of us ask our customers<br />

how we are doing. And what that ends up costing us.<br />

“Make it simple for your clients to give feedback”<br />

Asking for feedback is something we consider often when we deal with our clients. The simplest<br />

answers to “Why Don’t More <strong>Contractor</strong>s Ask for Feedback?”are: (1) It can be challenging to get<br />

the feedback so contractors give up on even asking, and (2) <strong>Contractor</strong>s don’t understand the<br />

significant value that such reviews can bring to their businesses long term.<br />

How to deal with these issues? First, make it simple for your clients to write feedback or to<br />

give you a review. Give them options for places to do this as opposed to just giving them one<br />

12 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

VOICES<br />

spot. Second, teach your staff why and how they should ask for<br />

reviews. Often the difference between getting feedback and not<br />

is in the way you ask for it.<br />

It should also be noted that many contractors are wary of<br />

negative responses. They shouldn’t be. Disappointing feedback<br />

is simply a tool to improve the way you do things.<br />

Jess Sugar<br />

“Paper feedback cards no longer seem to work”<br />

Oh, how I love client feedback. Funny, though, when you do a great<br />

job, you get a brief thank you. But when you make a mess, boy do<br />

you find out about it. The client will badmouth you all over the<br />

place, but never send you a note telling you what you did wrong. A<br />

phone call, yes, but never a note delineating the problem.<br />

We heard once that a client was so very ticked off at our<br />

service that they were telling all their friends about it. Then they<br />

told one of our really loyal clients about this – and got stopped<br />

in their tracks. Our loyal client asked our unhappy one, “Did you<br />

ever call them to tell them what was wrong?” The unhappy client<br />

answered, “Why would I do that? No one ever comes back to fix a<br />

mistake!” The reply from our loyal customer: “They do! Why did<br />

you not call?”<br />

So the next day, the customer calls and reams me out. I pull the<br />

file and note that there has never been any contact from the client<br />

since we left her premises two months ago. I ask what happened<br />

– and why did she not call? Apparently, after we left, her son tried<br />

to light a fire (in the fireplace we worked on) and smoked out the<br />

entire house and caused her to have an asthma attack. She had<br />

not used it since. So I offered her a free service call to find out<br />

what was going on. The finding? Her son had neglected to open<br />

the damper. It was that easy to solve. But because we had had no<br />

communication, we were badmouthed.<br />

For many years we left feedback cards with our clients, along<br />

with their invoices. We used to get 95 per cent of them back<br />

regularly – but that eventually changed to about 5 per cent.<br />

Maybe it is because we are doing a lot of repeat clients, I don’t<br />

know. We have tried putting a feedback area on our website – but<br />

hardly anything ever trickled in. Seems that clients do not want<br />

to give feedback anymore unless they are really mad at you.<br />

I think clients are so inundated with the auto-calling after nearly<br />

every service they have done, that when they see a paper or<br />

internet or mailing opportunity to give feedback they just toss it.<br />

We do still receive nice notes and cards with any incoming<br />

cheques from time to time and we really appreciate these as the<br />

clients have obviously taken more time and thought than just<br />

handing us a form they feel they must return. We keep these in<br />

a book in our sitting area. We also put any feedback that we get<br />

up on our website under testimonials.<br />

Yvette Aube<br />

“Whip out a tablet or mobile”<br />

I think one great way contractors can get immediate feedback on<br />

their work is to whip out a tablet or mobile with the site loaded<br />

up and ready to go. Have the client rate the service of work right<br />

there! This takes all the work out for the client, takes less than<br />

30 seconds to do, and you can reuse those testimonials to market<br />

your work – for years! Just imagine if you did that for every job!<br />

Win-win!<br />

Marci<br />

THE LITTLE VOICE THAT SAYS ”NO“<br />

Steve Maxwell posted online about that worrisome feeling<br />

that some clients just can’t help giving us<br />

when we are pitching our services to them,<br />

or giving them a quote. We have all blown<br />

past that signal in our guts. And we have all<br />

paid the price. Here is one reader’s personal<br />

experience…<br />

“Ask all potential clients this question”<br />

I think all of us in the construction business have had that<br />

negative gut feeling about potential clients, but have ignored<br />

the signals. One thing that I was taught years ago that has<br />

helped me immensely is to ask this question of a potential client:<br />

”Have you ever built before and how did it go for you?” In short<br />

order, the potential client will tell you about their fears, past<br />

experiences, and what they think of the construction industry.<br />

One of my best examples of how powerful this question is<br />

happened a number of years ago. We were building in an active<br />

new subdivision and a potential client came over and asked us<br />

if we could give him a price on his new build. It was a substantial<br />

house and, of course, I said sure. Then I asked “The Question.”<br />

He answered that, yes, he had built new houses twice before.<br />

I asked how that had gone for him. “I had to take both those<br />

“b_____’s” to court,” he replied. I said I was sorry to hear that<br />

and suggested he contact me when he had his final plans put<br />

together.<br />

When he called back a couple of weeks later, I told him I was<br />

booked solid. He burned the contractor who took on the contract<br />

for a substantial sum of money. By the way, he was a lawyer.<br />

Gavin Parsons<br />

14 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

VOICES<br />

ALBERTA RENOVATION WARRANTY PROGRAM<br />

In May, we wrote a brief news story about the<br />

launch of the new Alberta Home Renovation<br />

Warranty Program. We asked for feedback<br />

from the province’s builders. Here’s one of<br />

the responses.<br />

Money Grab<br />

I don’t think this Alberta Home Renovation Warranty Program will<br />

help home owners at all. If it is administered by the same people<br />

who run the Alberta New Home Warranty (Editor’s Note: It is) it<br />

will get the same results. I’ve worked for clients who have had<br />

their new homes leak – which led to extensive wood rot – because<br />

of poor building envelope work built during a boom by a major<br />

Calgary home builder. There were major renovation costs. They<br />

got nothing but a run-around and excuses from the builder. There<br />

are many people in the same situation, and I believe this is a<br />

major story here that most media do not want to address.<br />

Also the stringent application requirements (for this new<br />

program) will probably weed out 95 per cent or more of renovation<br />

contractors that would like to be accepted into the program.<br />

Homeowners should then probably be prepared to spend about<br />

40 per cent more for their renovations – if any contractor can<br />

possibly meet these high standards. If they exclude that many<br />

contractors by their extreme selection process, I would hazard<br />

a guess there wouldn’t be much point in needing a warranty<br />

then anyway<br />

Honestly, this is a money grab because they have gone to<br />

great effort to limit their liability right from the start.<br />

Ben Kuypers<br />

THROWING IN WORK FOR ’FREE’<br />

In our last issue’s<br />

editorials, Rob and Steve<br />

argued about when, if<br />

ever, it is a good idea<br />

to do minor additional<br />

work – as part of a larger<br />

renovation contract –<br />

for ’free.’ Here is how one<br />

Nova Scotia contractor<br />

sees it.<br />

’Extra cheese at no charge?’<br />

Doing freebies is risky, especially for new contractors with<br />

minimal experience trying to create a client base. My advice is<br />

to be careful. Several years ago while renovating a pizza shop<br />

in Sydney, Nova Scotia we were completing finish work when,<br />

unknown to me as supervisor, the client asked the carpenters<br />

to install additional shelving made from off-cuts from sheet<br />

goods used in the millwork. She thought the request was<br />

minimal and should be ’free.’ When I found out, attempting<br />

to protect my company’s interests and to help the client<br />

understand our business, I respectfully told the client that<br />

this would involve additional charges. I asked her, if after her<br />

restaurant is open for business and I order a pizza with extra<br />

cheese, can I get the extra cheese at no charge? She replied,<br />

’Certainly not: everyone knows cheese is very expensive.’ I<br />

replied, true, cheese is expensive. And extra shelving is like<br />

extra cheese to me.<br />

Michael Campbell<br />

Looking to offer your custom-build or renovation<br />

customers a premium heating system?<br />

Then attend Modern Hydronics – Summit <strong>2015</strong> and check out the<br />

space saving, energy efficient boilers • high-tech, sleek design radiators<br />

and baseboard • snow melt systems • insulated floor panels<br />

• hydronic cooling • geothermal options and more.<br />

In addition to seeing the products your event-pass gives you access to all<br />

hydronic experts’ sessions as well as lunch, dinner, drinks and free parking!<br />

Modern Hydronics - Summit <strong>2015</strong> takes place Sept 10 at the International Centre<br />

on Derry Rd in Mississauga. Hours are 10AM to 8PM<br />

<strong>Canadian</strong> <strong>Contractor</strong> readers qualify for a $50 discount. Use CCVIP when you<br />

register at www.modernhydronicssummit.com Call Kim at 416-510-6794 for assistance<br />

Summit_contractorad.indd 1<br />

16 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca<br />

15-06-29 10:04 AM

POWERFULLY CORDLESS.<br />

Festool cordless performs for uncompromising pros.<br />

With our expanded lineup, including the new TSC Track Saw, you<br />

get more freedom to work unplugged—without giving up your full<br />

capabilities. Details at festoolcanada.com<br />

© Copyright <strong>2015</strong> Festool USA, Tooltechnic Systems, LLC. All rights reserved.

FINANCIALS<br />

90 DAY<br />

PROFITABILITY<br />

CHALLENGE<br />

Do you know how much money you are going to<br />

make in the next 90 days? If you’re on salary, probably.<br />

But if you’re a self-employed contractor, probably not.<br />

Here’s how to get a better handle on the money<br />

coming your way in the next few months.<br />

By Mike Draper<br />

Although it is very common for contractors<br />

to not know how much they are going to<br />

make in the next three months, it doesn’t<br />

make it right. Imagine getting in a car with an<br />

unknown amount of gas in it – with a broken fuel<br />

gauge, no less – and embarking on a long road<br />

trip. You’d be asking for trouble, right? Well, the<br />

same thing applies to your business if you don’t<br />

know your profitability and cash flow for the<br />

months ahead.<br />

Not only do you need to know how your money<br />

is flowing in the months ahead to stop your<br />

business from running out of gas (cash), you also<br />

need to know how much money you are making so<br />

that you can know if what you are doing is giving<br />

you the results you want.<br />

Knowing how much you are going to make in<br />

the near future may seem like an impossible task.<br />

However, it is possible with some planning. There<br />

are three things that are required to figure it out.<br />

• How much work you are going to produce<br />

• How much that work will cost you<br />

• How much your overheads will be<br />

If you know the value of the work your company<br />

will produce in the next 90 days and you take away<br />

how much that work will cost you to do, and what<br />

your overhead costs will be, what you will be left<br />

with is your Net Profit.<br />

18 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

FINANCIALS<br />

Let’s take a moment to differentiate between Net Profit<br />

and Cash Flow. They are not the same thing. <strong>Contractor</strong>s<br />

often show a profit on their Profit and Loss statement, but<br />

they don’t have any money in the bank. That’s because<br />

the timing of payments received and payments going out<br />

doesn’t always coincide. For example, you may have to<br />

meet your payroll obligations before you get paid by the<br />

customer. You may also have to pay deposits or pay COD<br />

for materials before you get paid. Both of these examples<br />

will result in negative cash flow even though you show a<br />

profit.<br />

Let’s look at each of these three areas in more detail.<br />

Month 1 Month 2 Month 3 Total<br />

Revenue $50,000 $60,000 $50,000 $160,000<br />

Cost of Goods Sold $35,000 $42,000 $35,000 $112,000<br />

Gross Profit $15,000 $18,000 $15,000 $48,000<br />

Gross Profit % 30% 30% 30% 30%<br />

Overhead Expenses $8,000 $8,000 $8,000 $24,000<br />

Net Profit $7,000 $10,000 $7,000 $24,000<br />

How much will your company produce?<br />

Although you might not be able to know exactly how<br />

much work your team will do every day, you can take a<br />

look at your project management schedule at a high level.<br />

It should tell you what the planned timelines are for all<br />

your projects. By knowing the timelines of your projects,<br />

you can calculate the overall value of that work. This will<br />

give you your target revenue for the next 90 days.<br />

Even if you are not using a project management system<br />

you need to be able to estimate how much work or how<br />

many projects you plan to do over the next 90 days. This<br />

target now needs to drive your production. Taking control<br />

over the amount of work that your crews and subs deliver<br />

is a critical part of your success. Without a target and<br />

some control you will severely reduce your likelihood of<br />

success. The other major benefit of knowing how much to<br />

expect your company to produce over the next 90 days will<br />

help you better manage your cash flow. You need to make<br />

sure that the customer’s payment schedule is set up so<br />

that you don’t finance their project.<br />

Calculating the cost of the work performed<br />

If you know how much work you are expecting your crews<br />

and your subs to produce, then you should be able to<br />

calculate how much it will cost you to do that work – Cost<br />

of Goods Sold (COGS). The timing of when a sub will send<br />

you the invoice is not the critical point here. The critical<br />

point is to be able to review the estimates you produced<br />

before you won the project, to get the costs that you<br />

allocated to that work.<br />

The common point between how much will you<br />

produce and how much will it cost you to perform the work<br />

is that you must have a plan of what work you are going<br />

ILLUSTRATION: GLENN M C EVOY<br />

www.canadiancontractor.ca <strong>July</strong>/<strong>August</strong> <strong>2015</strong> 19

FINANCIALS<br />

To be truly successful and to<br />

be able to consistently make<br />

the money that you want to make,<br />

you have to have a project<br />

management schedule.<br />

ILLUSTRATION: GLENN M C EVOY<br />

to do. This is the hardest part of the process.<br />

I often see financial statements from contractors that do<br />

not allocate costs correctly. A very common mistake is to not<br />

include the payroll costs of workers and Workers’ Comp as part<br />

of COGS. Many contractors put them down as overheads. But<br />

for true project management, Cost of Goods Sold should include<br />

all expenses associated with doing the work including labour,<br />

material, sub-contractors, equipment rental, as well as Workers’<br />

Comp and payroll taxes for field personnel.<br />

There are many companies that sell project management or<br />

client management systems for this exact reason. To be truly<br />

successful and to be able to consistently make the money that<br />

you want to make, you have to have a project management<br />

schedule. Think about it like this. If you make a plan on paper<br />

and you don’t like the outcome of how much you will make in<br />

90 days, you have a chance to change the outcome before the<br />

90 days even start. If you don’t plan it and just wait to see the<br />

outcome 90 days from now, it is too late to do anything about it.<br />

If the amount of money you made was not to your liking there is<br />

nothing that you can do about it and you’ve just lost 90 days. Just<br />

as importantly, the next 90 days won’t be much different!<br />

The key to making money is to have a concrete plan and to<br />

continuously monitor your progress on the plan. Should you<br />

start to fall short of the plan, the sooner you can address the root<br />

cause of what is going wrong in the execution of the plan, the<br />

sooner you can take action to get back on track. To go back to the<br />

analogy of driving a car, if you know where you are planning to<br />

go and the route that you will take to get there, should you make<br />

a wrong turn you can figure out how to get back on course. You<br />

will reach your intended destination.<br />

Calculating Overhead<br />

Calculating overhead shouldn’t be too hard to do. You will have<br />

financial statements from previous months that you can use<br />

as a starting point to know what expenses you have had in the<br />

past and that you will likely have in the next 90 days. Simply<br />

put, overhead expenses will be all expenses that you will incur<br />

that you have not included in the cost of work performed. Typical<br />

overhead expenses will include administrative costs, owner’s<br />

wages if not included above, leases, rent, advertising, phones,<br />

insurance, internet, web site, truck repairs and gasoline, etc.<br />

Now add the cost of overhead and the cost of performing<br />

the work together. This number will be your total expenses for<br />

the next 90 days. Go back to the amount of work that you will<br />

produce and subtract the total expense number that you just<br />

calculated. The number that is left is how much you will make.<br />

20 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

FINANCIALS<br />

Hopefully that number is not only above zero but it equals how much money you want to make<br />

over the next 90 days. If it does equal what you want to make, then your next step is to follow<br />

your plan.<br />

Let’s take a look at what you can do if the number is not as much as you want to make in the<br />

next 90 days. First, I would suggest taking a look at your overhead to see what overhead items<br />

you could eliminate that would not impact your ability to produce the work that you do. Once<br />

removed, if the number is still not what you want to achieve, then the next step is to look at the<br />

work that you are planning to produce. There are only three possible scenarios here. Either (1)<br />

you are not producing enough work in the next 90 days, or (2) it is costing you too much to do it,<br />

or (3) you have a combination of both.<br />

At this point you will need to review the project plan to find out what can be done to increase<br />

production over the next 90 days. Look for areas of inefficiencies, areas where you could put<br />

multiple trades on-site at the same time, hire someone who can work faster or has larger crews<br />

that are able to produce more work in the same amount of time than someone you have worked<br />

with in the past. These may be tough decisions, but if the crews you have now can’t produce<br />

the work that you want then you might have to look for other crews. Are you willing to let your<br />

current crews stand in the way of you reaching your goals or are you going to take action to help<br />

you reach them?<br />

Take a look to see what options you have to reduce the cost to do the work without sacrificing<br />

your quality standard. You could look at doing a better job procuring material, shopping at<br />

different stores and using suppliers who can provide shipping to cut down on wasted time<br />

picking up and delivering materials to site. When I go to a building supply store during the day<br />

I am shocked at how many times I see two people from the same company walking around the<br />

store picking up materials or components that they forgot to get the time before. Better planning<br />

of the job can save a ton of time wasted going back to pick up more supplies.<br />

Research new products and technology that can make the job go faster. Make sure clients<br />

have made critical decisions that they need to make so that they don’t hold up the job. Any time<br />

that can be saved will help you produce more work in less time. More work means more money.<br />

The Break-Even Analysis<br />

If you still aren’t reaching your goals, you need to do a Break-Even Analysis to determine where<br />

you stand. If your revenues don’t support your expenses, you will get in trouble very quickly.<br />

Using the same numbers we used to determine your profitability, here is how you calculate<br />

break-even.<br />

Month 1 Month 2 Month 3 Total<br />

Overhead Expenses $8,000 $8,000 $8,000 $24,000<br />

Divided by Gross Profit % 30% 30% 30% 30%<br />

Break-Even Revenue $26,667 $26,667 $26,667 $80,000<br />

If you do all the things we just spoke about and you still won’t hit your goal, then it sounds<br />

like you need more sales. That is a whole other topic to be covered in the next issue of<br />

<strong>Canadian</strong> <strong>Contractor</strong>. cc<br />

Mike Draper is vice president, coaching, at Renovantage.com

KITCHENS<br />

SMART TECH<br />

Kitchens<br />

B y Kim L audrum<br />

This award-winning kitchen by XTC Design Inc., Toronto,<br />

brilliantly blends “streamlined and modern” with “warm<br />

and organic.”<br />

Photos: Larry Arnal Photography<br />

22 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

KITCHENS<br />

Kitchens, dollar for dollar, allow you<br />

to offer your renovation clients the<br />

best return on their investment.<br />

<strong>Canadian</strong> <strong>Contractor</strong> spoke to<br />

award-winning kitchen designers<br />

to find out the recent <strong>Canadian</strong><br />

kitchen trends that you need to<br />

be aware of.<br />

Hands-free and touchless features – “smart tech” in kitchen<br />

designer language – are all the rage in high-end kitchen<br />

renovations for up-market clients.<br />

“We’re seeing a lot more smart technology in kitchens<br />

today,” says Erica Westeroth, senior designer and partner, XTC<br />

Design Inc., Toronto. “There are more hands-free or touchless<br />

features in all kinds of applications, from faucets, cabinetry<br />

lighting, or even to operate cabinetry to lift doors out and up.”<br />

Installing smart tech in a kitchen requires a learning<br />

curve for most contractors, but it isn’t difficult, designers<br />

say. “There’s a whole mechanism that goes in behind the<br />

cabinetry. Blum makes the system, which includes a servo<br />

drive. They have a very good service program to help train<br />

tradespeople on installation,” Westeroth says.<br />

At his downtown Toronto showroom, Anthony Binns, a<br />

third-generation cabinetmaker, peers with a keen eye along<br />

a long length of white lacquered upper cabinetry made<br />

by German company Eggersmann. When installing smart<br />

technology, it’s important to have exact measurements. Any<br />

small shift can keep the smart boxes from “communicating<br />

with each other,” Binns says. This could cause a malfunction.<br />

The cabinet door might not lift with a finger press. The client<br />

is paying top dollar for this ease-of-use function, so accuracy<br />

is extremely important, notes Victoria Shaw, Binns’ partner at<br />

Eggersmann Toronto.<br />

Modern aesthetic<br />

“We’re also seeing cleaner lines, a trend toward a more<br />

modern aesthetic,” XTC’s Westeroth says. Hardware is linear<br />

or recessed. The layouts are simpler, not a lot of angles or<br />

curves. “Is it easier to install? It’s less time consuming. A more<br />

contemporary look does not require a lot of moldings, for<br />

example. But you can’t hide anything exacting.”<br />

www.canadiancontractor.ca <strong>July</strong>/<strong>August</strong> <strong>2015</strong> 23

KITCHENS<br />

Aesthetic lines are simpler so you have to add texture to the<br />

design for interest, Westeroth says. Riff-cut oak, for example, is a<br />

popular way to add texture and warmth.<br />

“People want modern with warmth,” Binns says. “They love<br />

simple lines and a well-organized kitchen.”<br />

Easy-to-access storage<br />

The popularity of cooking shows, Binns says, has influenced how<br />

people live in their homes now. Decades ago, guests would not have<br />

seen anything happening in the kitchen. Dinner would magically<br />

appear at the dining room table. But now, kitchens are integrated<br />

with family rooms as part of an entertainment hub. A well-organized<br />

kitchen is key to keeping it uncluttered. Efficient use of space, not<br />

necessarily more space, is key: “More storage isn’t always the<br />

answer,” Binns says.<br />

“A galley kitchen is the best way to cook, really. Everything<br />

Top: A stunning kitchen in the showroom of Eggersmann<br />

Toronto. It combines the beauty of wood grain with<br />

ultra-modern streamlining.<br />

Above: Anthony Binns and Victoria Shaw,<br />

principals, Eggersmann Toronto.<br />

24 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

KITCHENS<br />

is right within reach,” says Shaw.<br />

One of Eggersmann’s “wow” factor<br />

innovations is a feature wall that,<br />

when pressed, will turn a series of<br />

hidden doors to reveal floor to ceiling<br />

racks of kitchen storage. When placed<br />

behind the island, this creates a<br />

galley-type kitchen. But it can also be<br />

turned back into a dramatic feature<br />

wall.<br />

Another trend is to deploy fewer<br />

upper cabinets, Binns says. To<br />

demonstrate, he opens a drawer in an<br />

island and pulls out a wooden rack<br />

with dinner plates, which he then<br />

brings to the table. “Accessibility and<br />

ease-of-use is what it’s all about,” he<br />

says.<br />

Above and right: Ease-of-use features in today’s<br />

upmarket kitchen cabinets include “smart tech”<br />

functionality. Examples here are from Eggersmann<br />

Toronto.<br />

Lighting<br />

There is a big trend to using<br />

LED lighting in creative ways.<br />

One example is a line of blue<br />

lights recessed right into the<br />

cabinet doors as a way to add<br />

function and colour, as in this<br />

kitchen from ATD in Oakville, ON.<br />

LED lighting is energy efficient<br />

and doesn’t heat up like halogen<br />

does. It lasts much longer, too.<br />

26 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

Come to<br />

Toronto on<br />

our dime!<br />

Be a voice for<br />

our industry<br />

December 1 & 2, <strong>2015</strong><br />

We are looking<br />

for 32 contractors<br />

from across<br />

Canada who want:<br />

FREE<br />

• Travel to Toronto<br />

• Hotel<br />

• Food<br />

• Entry to Construct<br />

Canada<br />

AND<br />

who can share their<br />

business and product<br />

challenges.<br />

RenoFocus is a series of focus-group<br />

sessions behind closed doors in which<br />

manufacturers and suppliers gather market<br />

information from successful contractors.<br />

EMAIL Publisher Rob Koci<br />

for more information:<br />

rkoci@canadiancontractor.ca<br />

Please put RenoFocus in the subject line

KITCHENS<br />

Colour<br />

Like the striated lines of the riff-cut oak, colour is also used to add<br />

interest to the otherwise stark feel of the modern aesthetic.<br />

“It’s all a very personal thing,” notes Westeroth. “Some clients<br />

want a shot of red, purple, fuscia, chartreuse or cranberry red. Then<br />

there are others who are still too shy about it. They want beige,<br />

taupe or grey. It’s safer.”<br />

Fasten it Farther,<br />

Faster for Less.<br />

10X<br />

MORE<br />

COVERAGE<br />

HEAVY DUTY OR<br />

SUBFLOOR<br />

CARTRIDGES<br />

Compared to caulk, all-new Touch ‘n Foam Pro<br />

construction adhesives really go the distance<br />

on the shelf and<br />

on the job.<br />

New!<br />

XTC Design won the 2014 Kitchen and Bath award for a kitchen<br />

featuring purple walls with walnut cabinetry, a striated marble<br />

waterfall island, and porcelain-flooring tile. There is a wall of<br />

windows next to the kitchen, Westeroth explains, so there is a lot<br />

of natural light there, which allows the use of a darker colour<br />

in this location.<br />

Wood<br />

Sometimes a designer has to compromise.<br />

Westeroth found this to be true when her clients,<br />

a couple with discerning – and opposite – tastes,<br />

asked her to design a kitchen for them that was<br />

streamlined and modern for her, but warm and<br />

organic in feel for him. The result earned XTC<br />

Design another major Kitchen and Bath award,<br />

this time in <strong>2015</strong>. (See photo, pages 22-23.)<br />

The kitchen features stainless steel, butcher<br />

block and red lava-stone countertops. The<br />

apple-wood island features a striated pattern<br />

done on a horizontal grain. “The overall effect<br />

is very organic and natural. It had to read<br />

warm and comfortable,” Westeroth says.<br />

Wood remains an important feature<br />

in designing kitchens, says Shaw. In the<br />

Eggersmann showroom a feature wall of<br />

contrasting dark and light birch makes you<br />

feel as if you are standing among trees. It<br />

balances the harshness of concrete materials<br />

with nature.<br />

Touch’n Foam Adhesives Ad<br />

Retailer Version (option #1)<br />

See how you can fasten it<br />

farther, faster for less.<br />

For subfl oors, walls and other jobs, Touch ‘n Foam Pro Builder Series<br />

Construction Adhesives stick to budgets and schedules as well as lumber<br />

and drywall.<br />

FARTHER. Yielding 10x the linear feet of traditional adhesive caulks, Builder<br />

Series Construction Adhesives let you cover more footage with every can.<br />

FASTER. With fewer change-outs, your crews will make fast work of<br />

subfl oor and drywall installations.<br />

FOR LESS. Use fewer and cheaper fasteners with superior results.<br />

Convenience Products<br />

866 Horan Drive<br />

Fenton, MO 63026-2416 • (800) 325-6180<br />

Cabinetry<br />

“We do a lot of wood cabinetry and mix<br />

components a lot. We still do a lot of shaker<br />

cabinets because of their versatility. They can<br />

fit with contemporary or traditional design,”<br />

Westeroth says. “But the latest trend is to more<br />

clean lines.”<br />

Cabinet door finishes have improved<br />

dramatically, says Binns, as he demonstrates<br />

the mirror-like reflective quality of a lacquered<br />

board in his showroom. Edging, too, is<br />

improved, making it possible to mitre corners<br />

more easily. It all adds up to a greater selection<br />

for clients. cc<br />

Kim Laudrum is a regular contributor to<br />

<strong>Canadian</strong> <strong>Contractor</strong>.<br />

28 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

Style you can love and trust.<br />

When you build or renovate, the products you choose reflect you and your<br />

work. That’s why JELD-WEN offers stylish and reliable windows and doors<br />

to meet your highest expectations—and those of your customers. Whether<br />

you’re looking at rich hardwoods or durable vinyl, JELD-WEN’s award-winning<br />

products will complement any building or renovation project. What’s more,<br />

they’re energy efficient and backed by industry-leading warranties. Beauty plus<br />

performance—now that’s a winning combination!<br />

To learn more about top-performing<br />

windows and doors, visit jeld-wen.ca

COMPANY NEWS<br />

Good Works<br />

Building-products giant Saint-Gobain celebrates 350 years in<br />

business with a pledge to make builders out of disadvantaged youth<br />

By John Caulfield<br />

Saint-Gobain, the<br />

international buildingproducts<br />

manufacturer,<br />

is marking its 350th anniversary<br />

by strategically partnering<br />

with YouthBuild USA through a<br />

three-year $600,000 grant and a<br />

commitment to launch a trade<br />

school in South Africa.<br />

Since 2010, France-based Saint-<br />

Gobain – which is perhaps best<br />

known in Canada for the RSI and<br />

acoustical products it markets<br />

under the CertainTeed brand – has<br />

provided financial and building<br />

materials support to the Bostonbased<br />

YouthBuild USA, a nonprofit<br />

organization that provides<br />

education, counselling, and jobskills<br />

training to unemployed young<br />

American adults, generally highschool<br />

dropouts.<br />

That support has focused<br />

on the organization’s Green<br />

Initiative Program, a sustainable<br />

building and job-training program<br />

for disadvantaged youth; and<br />

specifically on YouthBuild<br />

programs in four communities<br />

where Saint-Gobain has business<br />

concentrations: Philadelphia, Penn.,<br />

Worcester, Mass., Schenectady, N.Y.,<br />

and Canton, Ohio.<br />

Saint Gobain, well-known in Canada for the CertainTeed brand,<br />

opened a series of public pavilions in Philadelphia recently. The<br />

LOOK pavilion is comprised of numerous mirrors inlaid with LEDs.<br />

By day, its exterior reflects the surrounding environment; by night<br />

it becomes a perpetually shifting cube of light. Saint-Gobain<br />

started as a mirror company in France in 1665.<br />

30 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

COMPANY NEWS<br />

Through this partnership in the U.S.,<br />

former out-of-school youth have been<br />

given the opportunity to build energyefficient<br />

homes in their neighborhoods<br />

while earning a high school diploma or<br />

its equivalent. Since its inception in 2010,<br />

the program has impacted more than<br />

1,050 YouthBuild students nationwide.<br />

And Saint-Gobain and YouthBuild USA<br />

have completed three U.S. Green Building<br />

Council (USGBC) LEED-certified homes.<br />

Its latest pledge brings Saint Gobain’s<br />

total funding of YouthBuild USA to<br />

$1.3 million over the course of seven years<br />

(2010-17). The extended partnership will<br />

make possible the following activities over<br />

the next three years:<br />

• YouthBuild Philadelphia Charter<br />

School will complete two projects already<br />

underway at Wingohocking Street in<br />

Philadelphia, launch a renovation of the<br />

school’s Community Celebration Room,<br />

and identify a third project.<br />

• YouthBuild Schenectady (operated by<br />

Social Enterprise and Training Center) will<br />

identify and complete a second project.<br />

• YouthBuild Worcester (operated by<br />

Training Resources of America, Inc.) will<br />

identify and complete a third project.<br />

• YouthBuild Canton (operated by<br />

Project REBUILD) will identify and<br />

complete its first project.<br />

• YouthBuild and Saint-Gobain will<br />

continue implementation of the “Scientists<br />

in the Classroom” program that leverages<br />

Saint-Gobain scientists and engineers<br />

to expose students to curriculum and<br />

careers in the fields of science, technology,<br />

engineering and mathematics (STEM).<br />

Showing love to the<br />

City of Brotherly Love<br />

Aside from announcing its expanded<br />

relationship with YouthBuild USA, Saint-<br />

Gobain has also pledged to reinforce its<br />

commitment to North America, where over<br />

the past five years alone it has invested<br />

more than $3 billion and where it currently<br />

employs 15,000 workers; as well as its<br />

connection with Philadelphia, which dates<br />

back to 1948. CertainTeed has long been<br />

based in the suburb of Valley Forge, Pa.<br />

The company is in the process of building<br />

a 43,000-square-foot Innovation Center<br />

and new headquarters on 65 acres in<br />

the suburb of Malvern, Pa. Last October,<br />

CertainTeed opened an R&D Lab on that<br />

campus.<br />

Saint-Gobain’s<br />

funding efforts<br />

have helped<br />

more than 1,050<br />

YouthBuild students<br />

nationwide.<br />

Philadelphia is one of only four cities<br />

worldwide – the others being Shanghai,<br />

Paris, and São Paulo – where Saint-Gobain<br />

this year will exhibit Future Sensations,<br />

a series of pavilions that showcase the<br />

company’s businesses and products<br />

in energy, aerospace, transportation,<br />

commercial and residential construction,<br />

medical and life sciences, and high tech.<br />

For example, the LOOK pavillion is<br />

comprised of numerous mirrors inlaid<br />

with LEDs. By day, its exterior reflects<br />

the surrounding environment; by night it<br />

becomes a perpetually shifting cube of<br />

light. The DISCOVER pavillion, which is<br />

exclusive to the Philadelphia exhibit, is<br />

a 70-foot dome that informs visitors about<br />

how the company’s products have impacted<br />

the lives of Americans. Perhaps the coolest<br />

pavilion is LISTEN, a padded cube that<br />

uses “spatialization” technology to ricochet<br />

different sounds throughout the booth.<br />

15 generations and counting<br />

To mark its 350th anniversary, Saint-<br />

Gobain has posted an online exhibition<br />

– www.saint-gobain350years.com – whose<br />

700 documents include a timeline of 22<br />

important dates in the company’s history,<br />

a 3D reconstruction of its glassworks<br />

as it would have been in operation<br />

in 1785, a gallery of innovations that<br />

showcases Saint-Gobain’s contributions to<br />

architecture and housing, and a scrapbook<br />

of its leaders, inventors, and other<br />

important employees.<br />

Nostalgia is nice, but Saint-Gobain<br />

also knows it’s in a “what have you done<br />

for me lately” world. Pierre-André de<br />

Chalendar, Saint-Gobain’s chairman and<br />

CEO, who flew in for the Philadelphia<br />

press conference, acknowledged that the<br />

company’s growth would continue to hinge<br />

on innovation. Saint-Gobain, he said, is<br />

“more focused on the future than the past,”<br />

and is on the lookout for “solutions” that<br />

can be expanded to other parts of the globe.<br />

Saint-Gobain currently has 182,000<br />

employees in 64 countries, including South<br />

Africa, where YouthBuild has operated<br />

for a decade, and where Saint-Gobain<br />

runs an accredited training program that<br />

prepares disadvantaged youth to work in<br />

the construction industry. Saint-Gobain<br />

and YouthBuild International plan to<br />

open a YouthBuild school in Samrand,<br />

South Africa, about 20 minutes from<br />

Johannesburg. Saint-Gobain will provide<br />

a training facility, trainers, and building<br />

materials. Initially, the program will serve<br />

50 disadvantaged youth. cc<br />

www.canadiancontractor.ca <strong>July</strong>/<strong>August</strong> <strong>2015</strong> 31

COMPANY NEWS<br />

CertainTeed targets <strong>Canadian</strong> builders<br />

The company’s insulation products now carry a Health Products Declaration, while its<br />

MemBrain moisture barrier product, developed in Europe, has now reached Canada<br />

CertainTeed MemBrain being installed.<br />

When homeowners talk about going green, they are<br />

actually “investing in their own comfort,” says Drew<br />

Brant, vice president of marketing for CertainTeed’s<br />

insulation division.<br />

So CertainTeed’s product development revolves around<br />

“comfort” on four levels: thermal performance, acoustics,<br />

air tightness, and moisture management.<br />

The challenge is distinguishing products that, to consumers<br />

and even some pros, seem a lot alike. “There’s not that much<br />

difference from batt to batt,” acknowledges Greg Silvestri,<br />

president of CertainTeed Insulation. What separates insulation<br />

suppliers, then, are often their relationships with customers. And at<br />

a time when some suppliers have backed away from the <strong>Canadian</strong><br />

market, CertainTeed, Silvestri says, is “redoubling” its efforts to<br />

serve Canada.<br />

Canada accounts for 15 per cent of annual worldwide insulation<br />

sales for Saint-Gobain, CertainTeed’s parent company. “Canada is<br />

still one of the world’s largest consumers of insulation,” says Drew.<br />

And it is clear that air tightness and sustainability are the hooks<br />

upon which CertainTeed is hanging its marketing hat.<br />

The company’s latest campaign trumpets fiberglass insulation<br />

as a better choice than stone wood insulation – a favorite among<br />

some <strong>Canadian</strong> contractors – because the manufacturing process<br />

uses far more recycled materials, it is more efficient to transport<br />

and easier to install, it costs less per square foot, and it rates<br />

at least as highly as stone wool for thermal resistance, sound<br />

performance, and restricting moisture infiltration.<br />

To further emphasize the advantages of fibreglass insulation,<br />

and to help builders and architects make informed specification<br />

decisions, CertainTeed in January issued the industry’s first Health<br />

Product Declarations for fibreglass insulation. The Declarations<br />

aim at establishing standards for a common reporting language<br />

for disclosing information about the ingredients used to make a<br />

building product and its associated health information.<br />

Air tightness goes hand in hand with moisture control for wall<br />

systems. And in May, CertainTeed Insulation Group Canada<br />

intoduced MemBrain, a patented polyamide-based material that<br />

the company is positioning as a “smart” alternative to poly vapour<br />

barrier sheeting.<br />

MemBrain, which has been available in Europe for a decade,<br />

is pricier than polyethylene sheeting: it will add between $300<br />

to $500 to the cost of an average 2,400-square-foot house. But<br />

CertainTeed contends the investment is worth the cost because<br />

its product adapts its permeability depending on different climate<br />

conditions. MemBrain’s water vapour permeability increases as<br />

the relative humidity in a wall cavity increases, thereby water<br />

vapour escapes the cavity easier, which in turn prevents mould<br />

and mildew.<br />

– John Caulfield<br />

32 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

REAL ESTATE<br />

Help your clients<br />

find the money<br />

Sonny Belanger of PLANiT Builders, Calgary, like an increasing number of contractors,<br />

has partnered up with Financeit, a “merchant direct” credit facility that provides funding<br />

to 70 per cent of his clients.<br />

By John Bleasby<br />

You’re a builder. You want to grow your business. But at the<br />

same time, growth can mean increased administration<br />

costs and collections issues. Perhaps you lose business<br />

because potential customers get bogged down with financial<br />

approval for a renovation, repair or addition. What do you do?<br />

Sonny Belanger of PLANiT Builders in Calgary thinks he has<br />

found the solution: a partnership with Financeit, a fast growing<br />

<strong>Canadian</strong> loan intermediary that allows builders instant and<br />

direct on-line access to consumer financing. It’s been a perfect fit<br />

for PLANiT, with their focus on garage construction and basement<br />

renovation.<br />

Like many contractors, Belanger often found the approval<br />

process at traditional banks too slow. Credit applications took 24<br />

hours or more, sometimes with requests for follow-up meetings.<br />

“It’s a fast-moving city; people want to make decisions quickly and<br />

move on with their lives. Financeit’s software allows us to confirm<br />

financing on the spot, literally in seconds.” For Belanger, putting<br />

these financing tools directly in his hands is unique and has given<br />

his business a marketable advantage.<br />

”They come to us for convenience,<br />

transparency and extremely<br />

competitive rates.”<br />

What kind of customer needs Financeit? Typical clients are<br />

young first-time home owners and dual-income professionals. They<br />

have good cash flow, yet hold insufficient equity in their homes to<br />

leverage a secured line of credit at a traditional bank. “They come<br />

to us for convenience, transparency and extremely competitive<br />

rates,” explains Financeit sales manager Dave Murray. “Through<br />

our builder partners, they have access to our credit facilities 24/7.<br />

Their personal financial information can even remain confidential<br />

from the builder, depending on the application. After approval, our<br />

customer service personnel look after them right to the end of the<br />

loan period.”<br />

Financeit started its<br />

merchant-direct financing<br />

program in 2011 and has<br />

grown rapidly in Canada<br />

with parallel programs in<br />

auto and marine/RV loans.<br />

“We are a technology<br />

platform, partnered with<br />

multiple financial institutions<br />

standing behind us, Murray<br />

says.” The company’s main<br />

thrust today is the home<br />

PLANiT Calgary team<br />

improvement market.<br />

Financeit offers unsecured,<br />

five year fixed rate loans up to $50,000, amortizations up to 15 years,<br />

and open monthly payments tailored to the client. Interest rates are<br />

comparable to new car loans, ie., well below credit card rates or<br />

”lenders-of-last-resort”.<br />

Most Financeit partners receive guaranteed payment upon<br />

project completion. Larger qualifying contactors like PLANiT receive<br />

full payment, 100 per cent upfront. The benefits of turning collections<br />

over to a finance company are potentially enormous, as any small<br />

to medium size contractor would recognise. Even dispute resolution,<br />

which Murray claims is minimal, is negotiated through Financeit.<br />

Providing instant loan approval to clients, coupled with<br />

an assurance of full payment, has had a powerful impact on<br />

Belanger’s business. He estimates 70 per cent of his clients use<br />

the facility. The resultant minimization of his administrative costs<br />

allows Belanger to focus his efforts on growth. As proof, Belanger<br />

estimates that PLANiT currently has teams working on over 170<br />

projects simultaneously across Alberta. “The jobs move much<br />

quicker. We don’t have to stop and wait to collect payment. Offering<br />

a full financing package as part of our services is very important;<br />

we’ve become very good at it.” cc<br />

34 <strong>July</strong>/<strong>August</strong> <strong>2015</strong> www.canadiancontractor.ca

CREATIVE EYE<br />

Shore House,<br />

North Shore, Vancouver<br />

Developer: Steve Hoiles<br />

Architect: Mark Kerschbaumer<br />

By John Bleasby<br />

Urban infill has become<br />

increasingly common in Canada’s<br />

larger municipalities as new building<br />

lots disappear. The challenges are varied:<br />

New designs should in some way blend<br />

in with the neighborhood, while at the<br />

same time upgraded zoning and code<br />

regulations are observed, neighbours<br />

sight lines respected; all this within a<br />

manageable project budget.<br />

In 2009, developer Steve Hoiles built<br />

a modern LEED house, on speculation,<br />

on half of a severed 66-foot-wide lot in<br />

Vancouver’s upscale North Shore<br />

neighborhood. Hoiles teamed up with<br />

architect and fellow Ontario transplant<br />

Mark Kerschbaumer in a collaboration<br />

of design and environmental awareness.<br />

“Like me, Steve has always been<br />

interested in the West Coast style of<br />

modernism. Other projects in North<br />

Vancouver were craftsman style; there<br />

simply was no supply for people looking<br />

for modern,” explains Kerschbaumer.<br />

The Highest-Rated<br />

LEED<br />

PLATINUM<br />

House in Canada<br />

Main Staircase<br />

The use of reclaimed wood beams from a demolished<br />

auto-repair shop, reshaped into the dramatic main staircase,<br />

as well as the roof beams, was an irony not lost on environmentallyconscious<br />

developer Steve Hoiles.<br />

The result was the Shore House, the<br />

country’s highest-rated LEED Platinum<br />

residence. The Hoiles/Kerschbaumer<br />

vision regarding design, budget<br />

($200 per square foot), energy efficiency,<br />

and reuse/recycling of materials<br />

established a new building template that<br />

can only be appreciated when one realizes<br />

that other builders at the time were<br />

building LEED-directed houses<br />

for $500 - $600 per square foot.<br />

Kerschbaummer applauds Hoiles on his<br />

methodology. “Steve was able to build<br />

a really energy-efficient house for not<br />

much more than others were building<br />

their standard homes” Hoiles, a<br />

self-described green-initiative developer,<br />

Continued on next page<br />

All Photos: Steve Hoiles<br />

Basement Suite<br />

The entrance to the<br />

separate 1,000 square foot<br />

apartment is below grade.<br />