MSR Review

EPD MSR Review Feasibility Study July 2015 1.02

EPD MSR Review Feasibility Study July 2015 1.02

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>MSR</strong> <strong>Review</strong> - Appendix A<br />

<strong>MSR</strong> 4 – Seaborg Technologies – Seaborg Waste Burner (SWaB)<br />

The SWaB prototype proposal is a 50MWth single fluid reactor that operates in the thermalepithermal<br />

spectrum. It is graphite moderated and fuelled by a combination of spent nuclear fuel<br />

and thorium. The design team based in Denmark, is a combination of physicists and chemists<br />

from the Niels Bohr Institute and the Technical University of Denmark.<br />

The fuel salt is a lithium-7 fluoride with dissolved thorium and fissile actinides from spent nuclear<br />

fuel. This is pumped through the graphite core and heat exchanger into a hold tank which is an<br />

important safety device. In most accident scenarios the fuel flows from this hold tank into a drain<br />

tank where it is rendered subcritical. A ‘freeze valve’ ▲ also exists as a secondary safety feature.<br />

The core itself consists of hexagonal graphite columns through which the fuel salt flows in the<br />

centre. An operating temperature of 700˚C is maintained by a secondary flow of coolant salt.<br />

The reactor relies on a novel, patent pending, on-board chemical fluorination flame reactor,<br />

based on the Fluorex process which can continually extract fission products from the salt during<br />

operation. This reprocessing system can process spent fuel pellets from conventional reactors<br />

whilst removing the uranium for other uses. The system is also used to adjust the fuel levels in the<br />

salt, avoiding the need for control rods. Shut down rods do exist in the core but primary reactivity<br />

control is via the coolant salt pump which changes the temperature of the fuel salt in the core<br />

thus altering reactivity due to its strong negative reactivity coefficient. This is a common feature<br />

to all <strong>MSR</strong> configurations.<br />

The inner vessel is formed of Hastelloy-N. A second barrier exists around the core and heat<br />

exchanger made of boron carbide clad in Hastelloy-N. This acts as a neutron and heat shield<br />

and as primary containment in the event of an extreme accident scenario where the inner vessel<br />

fails. The core, hold tank and off-gassing system are contained within a Ni-alloy vessel (3rd<br />

barrier). Finally, the core, reprocessing system, and dump tank are contained within a steel dome<br />

under large blocks of concrete underground.<br />

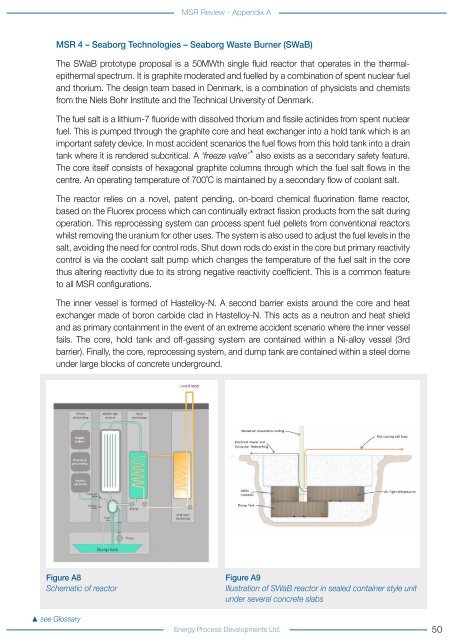

Figure A8<br />

Schematic of reactor<br />

▲ see Glossary<br />

Figure A9<br />

Illustration of SWaB reactor in sealed container style unit<br />

under several concrete slabs<br />

Energy Process Developments Ltd. 50