You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Application Fiberglass RHIB Aluminium HDPE Rhino<br />

Impact resistance Poor Good Excellent<br />

Repair ability Good Good Excellent<br />

Mass* (See Note below) Light Very Light Heavy<br />

General abuse resistance Poor Poor Excellent<br />

UV resistance Poor Excellent Excellent<br />

Maintenance requirements High High Low<br />

Sandy beach landing Good Good Good<br />

Rocky beach landing Poor Poor Excellent<br />

Puncture resistance Poor Good Excellent<br />

Table 1: ADVANTAGES OF HDPE VS FIBERGLASS & ALUMINIUM HULLS<br />

Note * The extra mass of HDPE hulls gives a large improvement on stability with higher potential safe top speeds<br />

<strong>RHINO</strong> <strong>CRAFT</strong> LIFTING PAD-EYES<br />

Rhino Craft are designed to be used as offshore daughter craft – as such they are liable to be<br />

subjected to significant abuse and over-load during launch and recovery.<br />

To cater for this our lifting pad-eyes are embedded into the hull structure such that it is impossible<br />

for the pad-eye plate to be ripped out. Besides this the lifting pad-eyes are reinforced with internal<br />

stainless steel bosses and doubler plates on either side. The bosses and doubler plates are close<br />

tolerance machined fits with auxiliary stainless steel bolts that are compositely designed with the<br />

parent HDPE plate such that the mode of failure requires that the boss and the bolts are<br />

simultaneously sheared through the HDPE plate to give a high bearing resistance coupled with a<br />

significant and progressive shear deformation before failure occurs.<br />

For good offshore lifting practice it is necessary that not only is there sufficient factor of safety<br />

relating to pad-eye failure, but also that it is possible to undertake periodical inspections to ensure<br />

that the pad-eyes have not been adversely overloaded. The system employed by Rhino Craft for the<br />

reinforced pad-eyes allows for visual testing to suffice as there will be no impairment of the padeye<br />

integrity unless there is significant visually identifiable plastic deformation that has taken place.<br />

Our standard lifting 3 Te SWL pad-eyes are designed to be used in conjunction with a standard 8.5<br />

Te SWL safety bow shackles.<br />

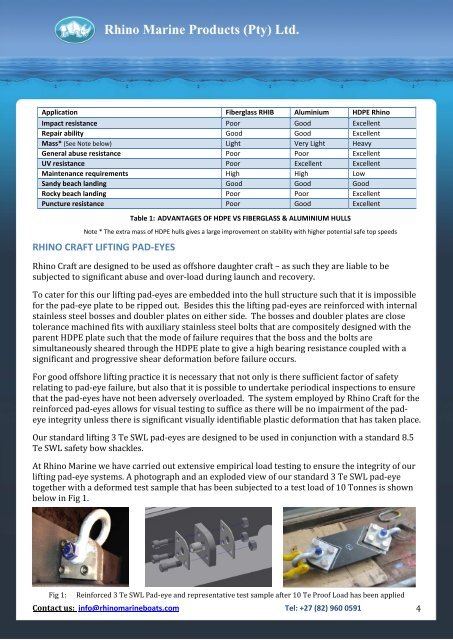

At Rhino Marine we have carried out extensive empirical load testing to ensure the integrity of our<br />

lifting pad-eye systems. A photograph and an exploded view of our standard 3 Te SWL pad-eye<br />

together with a deformed test sample that has been subjected to a test load of 10 Tonnes is shown<br />

below in Fig 1.<br />

Fig 1:<br />

Reinforced 3 Te SWL Pad-eye and representative test sample after 10 Te Proof Load has been applied<br />

Contact us: info@rhinomarineboats.com Tel: +27 (82) 960 0591 4