You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Guide of Mach long <strong>drill</strong><br />

Special features of MLD<br />

Tool for <strong>drill</strong>ing over 20D<br />

Special cutting edge preparation for low cutting load provides strong cutting edge.<br />

Special flute design focused on smooth chip evacuation.<br />

Rigid <strong>drill</strong> prevents bending of it when firstly enter the work piece.<br />

New TiAlN coating provides excellent lubrication property.<br />

Extremely smooth surface of coated layer by post treatment on top of coating.<br />

It is possible to <strong>drill</strong> over 20D depth, at one time with out step.<br />

Maximum qulaity could be acquired when using MQL system.<br />

Consistent tool life.<br />

Informations<br />

Work piece Carbon steel, alloy steel, mould steel, cast iron<br />

Recommendation (valid for 6 x 120(cutting edge length) x 170(total length)) Code system for Mach long <strong>drill</strong> (ex. MLD 0590-20A)<br />

Work piece Carbon steel<br />

(S45C)<br />

Notice for MLD<br />

Drill for machining over 20D<br />

Centering tolerance of Mach long <strong>drill</strong> from previously machined center of pilot <strong>drill</strong> should be within 0.01mm.<br />

The tolerance affects sudden facture of long <strong>drill</strong>.<br />

Composition for MQL system.<br />

MLD<br />

MQL System : Air in, 6bar(0.6Mpa) MQL system : Air in, 6bar(0.6Mpa), Coolant : Water soluble.<br />

Machining sequence for tilted face : Endmilling to make flat face Pilot <strong>drill</strong> Mach long <strong>drill</strong><br />

In case of tilted face, sphere shape, convex or concave face should have endmill process first.<br />

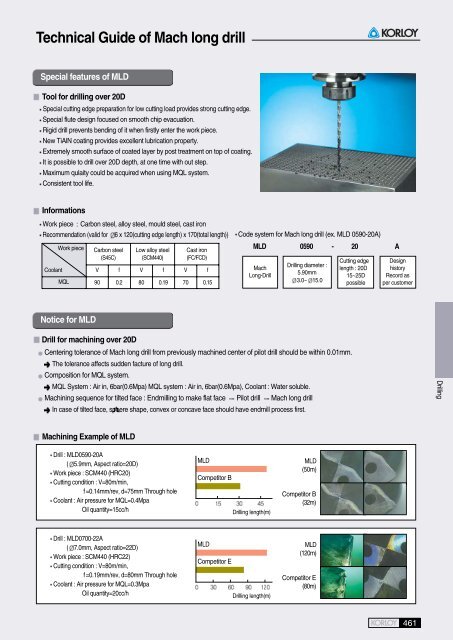

Machining Example of MLD<br />

Low alloy steel<br />

(SCM440)<br />

Drill : MLD0590-20A<br />

( 5.9mm, Aspect ratio=20D)<br />

Work piece : SCM440 (HRC20)<br />

Cutting condition : V=80m/min,<br />

f =0.14mm/rev, d=75mm Through hole<br />

Coolant : Air pressure for MQL=0.4Mpa<br />

Oil quantity=15cc/h<br />

Drill : MLD0700-22A<br />

( 7.0mm, Aspect ratio=22D)<br />

Work piece : SCM440 (HRC22)<br />

Cutting condition : V=80m/min,<br />

f =0.19mm/rev, d=80mm Through hole<br />

Coolant : Air pressure for MQL=0.3Mpa<br />

Oil quantity=20cc/h<br />

Cast iron<br />

(FC/FCD)<br />

Coolant V f V f V f<br />

MQL 90 0.2 80 0.19 70 0.15<br />

MLD<br />

Competitor B<br />

MLD<br />

Competitor E<br />

Mach<br />

Long-Drill<br />

Drilling length(m)<br />

Drilling length(m)<br />

0590<br />

Drilling diameter :<br />

5.90mm<br />

3.0~ 15.0<br />

MLD<br />

(50m)<br />

Competitor B<br />

(32m)<br />

MLD<br />

(120m)<br />

Competitor E<br />

(80m)<br />

-<br />

20<br />

Cutting edge<br />

length : 20D<br />

15~25D<br />

possible<br />

A<br />

Design<br />

history<br />

Record as<br />

per customer<br />

461<br />

Drilling