Technical Guide for C.B.N Inserts - isotool

Technical Guide for C.B.N Inserts - isotool

Technical Guide for C.B.N Inserts - isotool

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

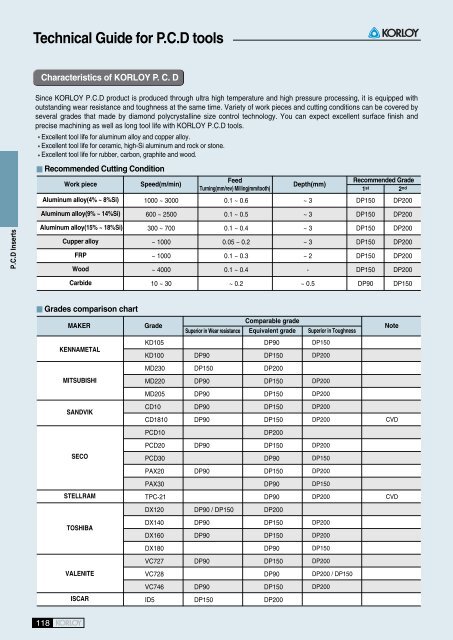

P.C.D <strong>Inserts</strong><br />

<strong>Technical</strong> <strong>Guide</strong> <strong>for</strong> P.C.D tools<br />

Characteristics of KORLOY P. C. D<br />

Since KORLOY P.C.D product is produced through ultra high temperature and high pressure processing, it is equipped with<br />

outstanding wear resistance and toughness at the same time. Variety of work pieces and cutting conditions can be covered by<br />

several grades that made by diamond polycrystalline size control technology. You can expect excellent surface finish and<br />

precise machining as well as long tool life with KORLOY P.C.D tools.<br />

Excellent tool life <strong>for</strong> aluminum alloy and copper alloy.<br />

Excellent tool life <strong>for</strong> ceramic, high-Si aluminum and rock or stone.<br />

Excellent tool life <strong>for</strong> rubber, carbon, graphite and wood.<br />

Recommended Cutting Condition<br />

118<br />

Work piece<br />

Aluminum alloy(4% ~ 8%Si)<br />

Aluminum alloy(9% ~ 14%Si)<br />

Aluminum alloy(15% ~ 18%Si)<br />

Cupper alloy<br />

FRP<br />

Wood<br />

Carbide<br />

Grades comparison chart<br />

Speed(m/min)<br />

MAKER Grade<br />

KENNAMETAL<br />

MITSUBISHI<br />

SANDVIK<br />

SECO<br />

STELLRAM<br />

TOSHIBA<br />

VALENITE<br />

ISCAR<br />

Feed<br />

Turning(mm/rev) Milling(mm/tooth)<br />

Depth(mm)<br />

1000 ~ 3000 0.1 ~ 0.6 ~ 3<br />

600 ~ 2500 0.1 ~ 0.5 ~ 3<br />

300 ~ 700 0.1 ~ 0.4 ~ 3<br />

~ 1000 0.05 ~ 0.2 ~ 3<br />

~ 1000 0.1 ~ 0.3 ~ 2<br />

~ 4000 0.1 ~ 0.4 -<br />

10 ~ 30 ~ 0.2 ~ 0.5<br />

KD105<br />

KD100<br />

MD230<br />

MD220<br />

MD205<br />

CD10<br />

CD1810<br />

PCD10<br />

PCD20<br />

PCD30<br />

PAX20<br />

PAX30<br />

TPC-21<br />

DX120<br />

DX140<br />

DX160<br />

DX180<br />

VC727<br />

VC728<br />

VC746<br />

ID5<br />

Superior in Wear resistance<br />

DP90<br />

DP150<br />

DP90<br />

DP90<br />

DP90<br />

DP90<br />

DP90<br />

DP90<br />

DP90 / DP150<br />

DP90<br />

DP90<br />

DP90<br />

DP90<br />

DP150<br />

Comparable grade<br />

Equivalent grade<br />

DP90<br />

DP150<br />

DP200<br />

DP150<br />

DP150<br />

DP150<br />

DP150<br />

DP200<br />

DP150<br />

DP90<br />

DP150<br />

DP90<br />

DP90<br />

DP200<br />

DP150<br />

DP150<br />

DP90<br />

DP150<br />

DP90<br />

DP150<br />

DP200<br />

Superior in Toughness<br />

DP150<br />

DP200<br />

DP200<br />

DP200<br />

DP200<br />

DP200<br />

DP200<br />

DP150<br />

DP200<br />

DP150<br />

DP200<br />

DP200<br />

DP200<br />

DP150<br />

DP200<br />

DP200 / DP150<br />

DP200<br />

Recommended Grade<br />

1 st 2 nd<br />

DP150<br />

DP150<br />

DP150<br />

DP150<br />

DP150<br />

DP150<br />

DP90<br />

Note<br />

CVD<br />

CVD<br />

DP200<br />

DP200<br />

DP200<br />

DP200<br />

DP200<br />

DP200<br />

DP150