Press book

2016-winners-of-the-queen_s-awards-for-enterprise-press-book

2016-winners-of-the-queen_s-awards-for-enterprise-press-book

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

North West<br />

Innovation<br />

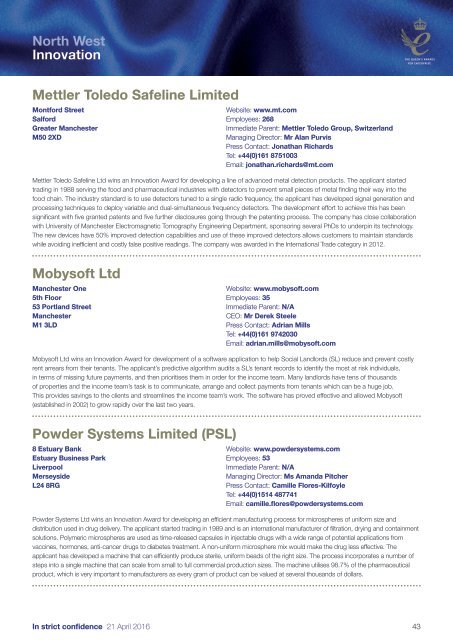

Mettler Toledo Safeline Limited<br />

Montford Street<br />

Salford<br />

Greater Manchester<br />

M50 2XD<br />

Website: www.mt.com<br />

Employees: 268<br />

Immediate Parent: Mettler Toledo Group, Switzerland<br />

Managing Director: Mr Alan Purvis<br />

<strong>Press</strong> Contact: Jonathan Richards<br />

Tel: +44(0)161 8751003<br />

Email: jonathan.richards@mt.com<br />

Mettler Toledo Safeline Ltd wins an Innovation Award for developing a line of advanced metal detection products. The applicant started<br />

trading in 1988 serving the food and pharmaceutical industries with detectors to prevent small pieces of metal finding their way into the<br />

food chain. The industry standard is to use detectors tuned to a single radio frequency, the applicant has developed signal generation and<br />

processing techniques to deploy variable and dual-simultaneous frequency detectors. The development effort to achieve this has been<br />

significant with five granted patents and five further disclosures going through the patenting process. The company has close collaboration<br />

with University of Manchester Electromagnetic Tomography Engineering Department, sponsoring several PhDs to underpin its technology.<br />

The new devices have 50% improved detection capabilities and use of these improved detectors allows customers to maintain standards<br />

while avoiding inefficient and costly false positive readings. The company was awarded in the International Trade category in 2012.<br />

Mobysoft Ltd<br />

Manchester One<br />

5th Floor<br />

53 Portland Street<br />

Manchester<br />

M1 3LD<br />

Website: www.mobysoft.com<br />

Employees: 35<br />

Immediate Parent: N/A<br />

CEO: Mr Derek Steele<br />

<strong>Press</strong> Contact: Adrian Mills<br />

Tel: +44(0)161 9742030<br />

Email: adrian.mills@mobysoft.com<br />

Mobysoft Ltd wins an Innovation Award for development of a software application to help Social Landlords (SL) reduce and prevent costly<br />

rent arrears from their tenants. The applicant’s predictive algorithm audits a SL’s tenant records to identify the most at risk individuals,<br />

in terms of missing future payments, and then prioritises them in order for the income team. Many landlords have tens of thousands<br />

of properties and the income team’s task is to communicate, arrange and collect payments from tenants which can be a huge job.<br />

This provides savings to the clients and streamlines the income team’s work. The software has proved effective and allowed Mobysoft<br />

(established in 2002) to grow rapidly over the last two years.<br />

Powder Systems Limited (PSL)<br />

8 Estuary Bank<br />

Estuary Business Park<br />

Liverpool<br />

Merseyside<br />

L24 8RG<br />

Website: www.powdersystems.com<br />

Employees: 53<br />

Immediate Parent: N/A<br />

Managing Director: Ms Amanda Pitcher<br />

<strong>Press</strong> Contact: Camille Flores-Kilfoyle<br />

Tel: +44(0)1514 487741<br />

Email: camille.flores@powdersystems.com<br />

Powder Systems Ltd wins an Innovation Award for developing an efficient manufacturing process for microspheres of uniform size and<br />

distribution used in drug delivery. The applicant started trading in 1989 and is an international manufacturer of filtration, drying and containment<br />

solutions. Polymeric microspheres are used as time-released capsules in injectable drugs with a wide range of potential applications from<br />

vaccines, hormones, anti-cancer drugs to diabetes treatment. A non-uniform microsphere mix would make the drug less effective. The<br />

applicant has developed a machine that can efficiently produce sterile, uniform beads of the right size. The process incorporates a number of<br />

steps into a single machine that can scale from small to full commercial production sizes. The machine utilises 98.7% of the pharmaceutical<br />

product, which is very important to manufacturers as every gram of product can be valued at several thousands of dollars.<br />

In strict confidence 21 April 2016<br />

43