Roofing

Roofing%20Today%20Issue%2062%20January%202016

Roofing%20Today%20Issue%2062%20January%202016

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Modular <strong>Roofing</strong><br />

How About Not Working at Height?<br />

John Cunningham, Managing Director of Metrotile UK<br />

Removing Risks<br />

There are two new types of housebuilding which can remove working at<br />

height risks almost completely.<br />

Firstly, factory built houses. In this instance, working at height risks are<br />

reduced by the modular buildings being assembled in the factory and<br />

transported whole to the site itself. The alternative is to take the factory to the<br />

site – creating a pop-up factory at a location site where transport demands<br />

make this option more cost-effective.<br />

Secondly, we are keen for housebuilders in particular to start thinking about<br />

building roofs on the floor and then lifting them on to the supporting<br />

structures. There are so many benefits to this method. But it requires some outof-the-box<br />

thinking to become common practice.<br />

Housing Shortage<br />

The other issue to consider is the major housing shortage in this country. The<br />

Chancellor has kick-started a programme for to build 400,000 new homes, with<br />

200,000 new starter homes set to be built in this Government alone. Why not<br />

remove one of the restraints on such a programme – namely the burden of<br />

health and safety and working at height regulations – by finally<br />

adopting technologies which would make housebuilding so much<br />

more straightforward than it is with traditional roofing methods?<br />

They have been doing it in Europe for decades and it’s about time<br />

we started doing it here, too.<br />

Now, I recognise that the adoption of new techniques will have<br />

an impact on the roofing industry and will be a concern for roofers<br />

who lack the installation training required. New technologies<br />

always raise fears for people who do things a certain way. But no<br />

one is expecting lightweight roofing to become the industry status<br />

quo overnight and we would encourage roofers to add new skills<br />

to their armoury. Wouldn’t it be better to receive some training<br />

and work in a less risky environment, rather than to continue<br />

working with the ever-present danger of the worst that could<br />

happen?<br />

John Cunningham is managing director of Metrotile UK –<br />

manufacturers of lightweight steel roof tiles. Based in Chippenham<br />

in Wiltshire.<br />

The Government’s relaunch of Working at Height<br />

guidance in 2014 suggested two problems within<br />

our industry. Firstly, that the existing working<br />

regulations were wasting time and money for<br />

British businesses. Secondly, that falls continue to<br />

remain one of the biggest causes of serious<br />

workplace injury – with more than 40 people killed<br />

and 4,000 suffering major injuries every year.<br />

Recent campaigns have aimed to tackle these<br />

issues but no amount of assessments and<br />

regulations can avoid the simple equation: that<br />

working at height involves gravity and weight and<br />

is therefore dangerous.<br />

I would like to propose a solution which I believe<br />

tackles both of these issues – easily, and cost<br />

effectively. How about not working at height at all?<br />

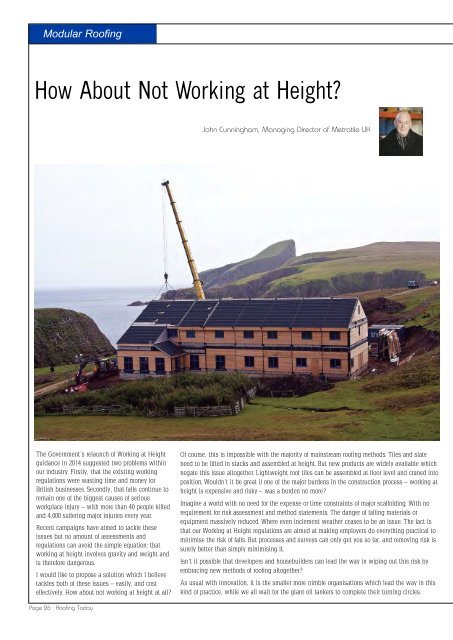

Of course, this is impossible with the majority of mainstream roofing methods. Tiles and slate<br />

need to be lifted in stacks and assembled at height. But new products are widely available which<br />

negate this issue altogether. Lightweight roof tiles can be assembled at floor level and craned into<br />

position. Wouldn’t it be great if one of the major burdens in the construction process – working at<br />

height is expensive and risky – was a burden no more?<br />

Imagine a world with no need for the expense or time constraints of major scaffolding. With no<br />

requirement for risk assessment and method statements. The danger of falling materials or<br />

equipment massively reduced. Where even inclement weather ceases to be an issue. The fact is<br />

that our Working at Height regulations are aimed at making employers do everything practical to<br />

minimise the risk of falls. But processes and surveys can only get you so far, and removing risk is<br />

surely better than simply minimising it.<br />

Isn’t it possible that developers and housebuilders can lead the way in wiping out this risk by<br />

embracing new methods of roofing altogether?<br />

As usual with innovation, it is the smaller more nimble organisations which lead the way in this<br />

kind of practice, while we all wait for the giant oil tankers to complete their turning circles.<br />

Page 26 <strong>Roofing</strong> Today <strong>Roofing</strong> Today Page 27<br />

Enquiry 5