Schaltmatten_Keypads

Schaltmatten , Keypads

Schaltmatten , Keypads

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

KEYPADS<br />

Manufacturing Process<br />

All of conductive rubber keypads and switches are compression-molded in precise carbon sreel tools using highly elastic,<br />

non-toxic silicone rubber compounds.<br />

After molding, all keypads are subjected to a two-hour post-curing cycle at a temperature of 200 o C. Post curing is essential to the<br />

manufacturing process because it removes catalyst and oxidant residue retained by the keypad during the molding process,<br />

stabilizes the physical properties of the silicone and increases thermal stability.<br />

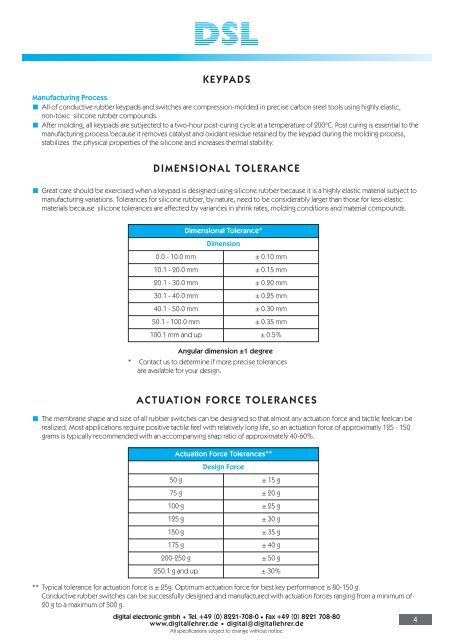

DIMENSIONAL TOLERANCE<br />

Great care should be exercised when a keypad is designed using silicone rubber because it is a highly elastic material subject to<br />

manufacturing variations. Tolerances for silicone rubber, by nature, need to be considerably larger than those for less-elastic<br />

materials because silicone tolerances are affected by variances in shrink rates, molding conditions and material compounds.<br />

Dimensional Tolerance*<br />

Dimension<br />

0.0 - 10.0 mm ± 0.10 mm<br />

10.1 - 20.0 mm ± 0.15 mm<br />

20.1 - 30.0 mm ± 0.20 mm<br />

30.1 - 40.0 mm ± 0.25 mm<br />

40.1 - 50.0 mm ± 0.30 mm<br />

50.1 - 100.0 mm ± 0.35 mm<br />

100.1 mm and up ± 0.5%<br />

Angular dimension ±1 degree<br />

* Contact us to determine if more precise tolerances<br />

are available for your design.<br />

ACTUATION FORCE TOLERANCES<br />

The membrane shape and size of all rubber switches can be designed so that almost any actuation force and tactile feelcan be<br />

realized. Most applications require positive tactile feel with relatively long life, so an actuation force of approximatly 125 - 150<br />

grams is typically recommended with an accompanying snap ratio of approximately 40-60%.<br />

Actuation Force Tolerances**<br />

Design Force<br />

50 g ± 15 g<br />

75 g ± 20 g<br />

100 g ± 25 g<br />

125 g ± 30 g<br />

150 g ± 35 g<br />

175 g ± 40 g<br />

200-250 g ± 50 g<br />

250.1 g and up ± 30%<br />

** Typical tolerance for actuation force is ± 25g. Optimum actuation force for best key performance is 80-150 g.<br />

Conductive rubber switches can be successfully designed and manufactured with actuation forces ranging from a minimum of<br />

20 g to a maximum of 500 g.<br />

digital electronic gmbh Tel. +49 (0) 8221-708-0 Fax +49 (0) 8221 708-80<br />

www.digitallehrer.de digital@digitallehrer.de<br />

All specifications subject to change without notice.<br />

4