EISELE Inoxline_en

Eisele INOXLINE – stainless, hygienic, easy-to-clean, sanitary Stainless steel push-in fittings for food, pharmaceuticals and paints The stainless steel push-in fittings of the Eisele INOXLINE are manufactured of corrosion-free and acid-resistant stainless steel in high material quality. All parts are completely machined from solid material and are particularly well-suited for hygiene-sensitive applications in the food and pharmaceutical industry. Based on the design of our proven standardised pneumatic connectors Eisele INOXLINE stainless steel push-in fittings can be easily and completely cleaned, thanks to the stainless materials used and the surface treatment. INOXLINE also includes stainless threaded connections that are dead-zone free and joint-free. Due to the sanitary design production residues cannot remain. Eisele INOXLINE stainless steel push-in fittings and stainless threaded connections are also easily cleanable from the outside, due to precise surface processing. Stainless Eisele INOXLINE components can also be used in sterile environments. The quality workmanship and the low manufacturing tolerances of our stainless steel push-in fittings and stainless threaded connections are particularly noticeable in the INOXLINE products.

Eisele INOXLINE – stainless, hygienic, easy-to-clean, sanitary

Stainless steel push-in fittings for food, pharmaceuticals and paints

The stainless steel push-in fittings of the Eisele INOXLINE are manufactured of corrosion-free and acid-resistant stainless steel in high material quality. All parts are completely machined from solid material and are particularly well-suited for hygiene-sensitive applications in the food and pharmaceutical industry. Based on the design of our proven standardised pneumatic connectors Eisele INOXLINE stainless steel push-in fittings can be easily and completely cleaned, thanks to the stainless materials used and the surface treatment.

INOXLINE also includes stainless threaded connections that are dead-zone free and joint-free. Due to the sanitary design production residues cannot remain. Eisele INOXLINE stainless steel push-in fittings and stainless threaded connections are also easily cleanable from the outside, due to precise surface processing. Stainless Eisele INOXLINE components can also be used in sterile environments. The quality workmanship and the low manufacturing tolerances of our stainless steel push-in fittings and stainless threaded connections are particularly noticeable in the INOXLINE products.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Plastic hoses<br />

76<br />

PE, PU, Eisele ProWeld, PTFE / FEP<br />

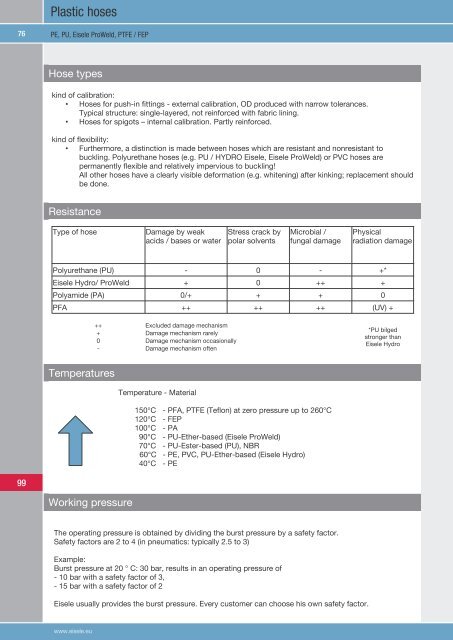

Hose types<br />

kind of calibration:<br />

• Hoses for push-in fittings - external calibration, OD produced with narrow tolerances.<br />

Typical structure: single-layered, not reinforced with fabric lining.<br />

• Hoses for spigots – internal calibration. Partly reinforced.<br />

kind of flexibility:<br />

• Furthermore, a distinction is made betwe<strong>en</strong> hoses which are resistant and nonresistant to<br />

buckling. Polyurethane hoses (e.g. PU / HYDRO Eisele, Eisele ProWeld) or PVC hoses are<br />

perman<strong>en</strong>tly flexible and relatively impervious to buckling!<br />

All other hoses have a clearly visible deformation (e.g. whit<strong>en</strong>ing) after kinking; replacem<strong>en</strong>t should<br />

be done.<br />

Resistance<br />

Type of hose<br />

Damage by weak<br />

acids / bases or water<br />

Stress crack by<br />

polar solv<strong>en</strong>ts<br />

Microbial /<br />

fungal damage<br />

Physical<br />

radiation damage<br />

Polyurethane (PU) - 0 - +*<br />

Eisele Hydro/ ProWeld + 0 ++ +<br />

Polyamide (PA) 0/+ + + 0<br />

PFA ++ ++ ++ (UV) +<br />

++ Excluded damage mechanism<br />

+ Damage mechanism rarely<br />

0 Damage mechanism occasionally<br />

- Damage mechanism oft<strong>en</strong><br />

*PU bilged<br />

stronger than<br />

Eisele Hydro<br />

Temperatures<br />

Temperature - Material<br />

150°C - PFA, PTFE (Teflon) at zero pressure up to 260°C<br />

120°C - FEP<br />

100°C - PA<br />

90°C - PU-Ether-based (Eisele ProWeld)<br />

70°C - PU-Ester-based (PU), NBR<br />

60°C - PE, PVC, PU-Ether-based (Eisele Hydro)<br />

40°C - PE<br />

99<br />

Working pressure<br />

The operating pressure is obtained by dividing the burst pressure by a safety factor.<br />

Safety factors are 2 to 4 (in pneumatics: typically 2.5 to 3)<br />

Example:<br />

Burst pressure at 20 ° C: 30 bar, results in an operating pressure of<br />

- 10 bar with a safety factor of 3,<br />

- 15 bar with a safety factor of 2<br />

Eisele usually provides the burst pressure. Every customer can choose his own safety factor.<br />

www.eisele.eu