QSI Height Safety Catalogue 2015

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

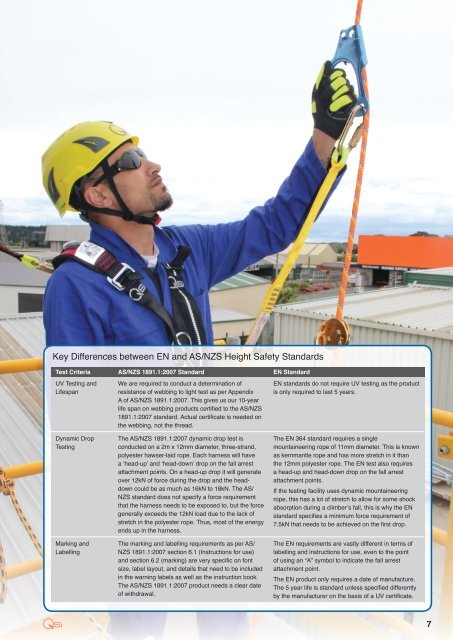

Key Differences between EN and AS/NZS <strong>Height</strong> <strong>Safety</strong> Standards<br />

Test Criteria AS/NZS 1891.1:2007 Standard EN Standard<br />

UV Testing and<br />

Lifespan<br />

Dynamic Drop<br />

Testing<br />

Marking and<br />

Labelling<br />

We are required to conduct a determination of<br />

resistance of webbing to light test as per Appendix<br />

A of AS/NZS 1891.1:2007. This gives us our 10-year<br />

life span on webbing products certified to the AS/NZS<br />

1891.1:2007 standard. Actual certificate is needed on<br />

the webbing, not the thread.<br />

The AS/NZS 1891.1:2007 dynamic drop test is<br />

conducted on a 2m x 12mm diameter, three-strand,<br />

polyester hawser-laid rope. Each harness will have<br />

a ‘head-up’ and ‘head-down’ drop on the fall arrest<br />

attachment points. On a head-up drop it will generate<br />

over 12kN of force during the drop and the headdown<br />

could be as much as 16kN to 18kN. The AS/<br />

NZS standard does not specify a force requirement<br />

that the harness needs to be exposed to, but the force<br />

generally exceeds the 12kN load due to the lack of<br />

stretch in the polyester rope. Thus, most of the energy<br />

ends up in the harness.<br />

The marking and labelling requirements as per AS/<br />

NZS 1891.1:2007 section 6.1 (Instructions for use)<br />

and section 6.2 (marking) are very specific on font<br />

size, label layout, and details that need to be included<br />

in the warning labels as well as the instruction book.<br />

The AS/NZS 1891.1:2007 product needs a clear date<br />

of withdrawal.<br />

EN standards do not require UV testing as the product<br />

is only required to last 5 years.<br />

The EN 364 standard requires a single<br />

mountaineering rope of 11mm diameter. This is known<br />

as kernmantle rope and has more stretch in it than<br />

the 12mm polyester rope. The EN test also requires<br />

a head-up and head-down drop on the fall arrest<br />

attachment points.<br />

If the testing facility uses dynamic mountaineering<br />

rope, this has a lot of stretch to allow for some shock<br />

absorption during a climber’s fall, this is why the EN<br />

standard specifies a minimum force requirement of<br />

7.5kN that needs to be achieved on the first drop.<br />

The EN requirements are vastly different in terms of<br />

labelling and instructions for use, even to the point<br />

of using an “A” symbol to indicate the fall arrest<br />

attachment point.<br />

The EN product only requires a date of manufacture.<br />

The 5 year life is standard unless specified differently<br />

by the manufacturer on the basis of a UV certificate.<br />

7