BS&B Graphite Disk Brochure - G&W Industrial Sales in Parkersburg ...

BS&B Graphite Disk Brochure - G&W Industrial Sales in Parkersburg ...

BS&B Graphite Disk Brochure - G&W Industrial Sales in Parkersburg ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Vent<strong>in</strong>g Capacities<br />

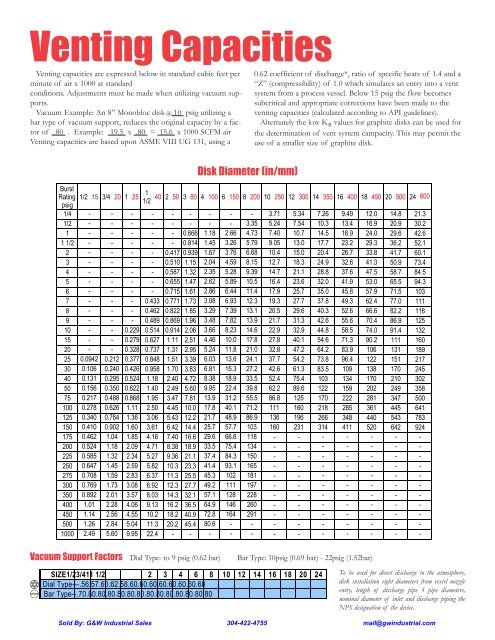

Vent<strong>in</strong>g capacities are expressed below <strong>in</strong> standard cubic feet per<br />

m<strong>in</strong>ute of air x 1000 at standard<br />

conditions. Adjustments must be made when utiliz<strong>in</strong>g vacuum supports.<br />

Vacuum Example: An 8” Monobloc disk @ 10 psig utiliz<strong>in</strong>g a<br />

bar type of vacuum support, reduces the orig<strong>in</strong>al capacity by a factor<br />

of .80 . Example: 19.5 x .80 = 15.6 x 1000 SCFM air<br />

Vent<strong>in</strong>g capacities are based upon ASME VIII UG 131, us<strong>in</strong>g a<br />

Burst<br />

Rat<strong>in</strong>g<br />

psig<br />

1/4<br />

1/2<br />

1<br />

1 1/2<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

15<br />

20<br />

25<br />

30<br />

40<br />

50<br />

75<br />

100<br />

125<br />

150<br />

175<br />

200<br />

225<br />

250<br />

275<br />

300<br />

350<br />

400<br />

450<br />

500<br />

1000<br />

1/2 15 3/4 20 1 25 1<br />

1/2<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

0.0942<br />

0.106<br />

0.131<br />

0.156<br />

0.217<br />

0.278<br />

0.340<br />

0.410<br />

0.462<br />

0.524<br />

0.585<br />

0.647<br />

0.708<br />

0.769<br />

0.892<br />

1.01<br />

1.14<br />

1.26<br />

2.49<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

0.212<br />

0.240<br />

0.295<br />

0.350<br />

0.488<br />

0.626<br />

0.764<br />

0.902<br />

1.04<br />

1.18<br />

1.32<br />

1.45<br />

1.59<br />

1.73<br />

2.01<br />

2.28<br />

2.56<br />

2.84<br />

5.60<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

0.229<br />

0.279<br />

0.328<br />

0.377<br />

0.426<br />

0.524<br />

0.622<br />

0.868<br />

1.11<br />

1.36<br />

1.60<br />

1.85<br />

2.09<br />

2.34<br />

2.59<br />

2.83<br />

3.08<br />

3.57<br />

4.06<br />

4.55<br />

5.04<br />

9.95<br />

<strong>Disk</strong> Diameter (<strong>in</strong>/mm)<br />

0.62 coefficient of discharge*, ratio of specific heats of 1.4 and a<br />

“Z” (compressibility) of 1.0 which simulates an entry <strong>in</strong>to a vent<br />

system from a process vessel. Below 15 psig the flow becomes<br />

subcritical and appropriate corrections have been made to the<br />

vent<strong>in</strong>g capacities (calculated accord<strong>in</strong>g to API guidel<strong>in</strong>es).<br />

Alternately the low K R values for graphite disks can be used for<br />

the determ<strong>in</strong>ation of vent system campacity. This may permit the<br />

use of a smaller size of graphite disk.<br />

40 2 50 3 80 4 100 6 150 8 200 10 250 12 300 14 350 16 400 18 450 20 500 24 600<br />

- - - -<br />

- - - -<br />

- - 0.666 1.18<br />

- - 0.814 1.45<br />

- 0.417 0.939 1.67<br />

- 0.510 1.15 2.04<br />

- 0.587 1.32 2.35<br />

- 0.655 1.47 2.62<br />

- 0.715 1.61 2.86<br />

0.433 0.771 1.73 3.08<br />

0.462 0.822 1.85 3.29<br />

0.489 0.869 1.96 3.48<br />

0.514 0.914 2.06 3.66<br />

0.627 1.11 2.51 4.46<br />

0.737 1.31 2.95 5.24<br />

0.848 1.51 3.39 6.03<br />

0.958 1.70 3.83 6.81<br />

1.18 2.40 4.72 8.38<br />

1.40 2.49 5.60 9.95<br />

1.95 3.47 7.81 13.9<br />

2.50 4.45 10.0 17.8<br />

3.06 5.43 12.2 21.7<br />

3.61 6.42 14.4 25.7<br />

4.16 7.40 16.6 29.6<br />

4.71 8.38 18.9 33.5<br />

5.27 9.36 21.1 37.4<br />

5.82 10.3 23.3 41.4<br />

6.37 11.3 25.5 45.3<br />

6.92 12.3 27.7 49.2<br />

8.03 14.3 32.1 57.1<br />

9.13 16.2 36.5 64.9<br />

10.2 18.2 40.9 72.8<br />

11.3 20.2 45.4 80.6<br />

22.4 - - -<br />

- - 3.71 5.34 7.26 9.49 12.0 14.8<br />

- 3.35 5.24 7.54 10.3 13.4 16.9 20.9<br />

2.66 4.73 7.40 10.7 14.5 18.9 24.0 29.6<br />

3.26 5.79 9.05 13.0 17.7 23.2 29.3 36.2<br />

3.76 6.68 10.4 15.0 20.4 26.7 33.8 41.7<br />

4.59 8.15 12.7 18.3 24.9 32.6 41.3 50.9<br />

5.28 9.39 14.7 21.1 28.8 37.6 47.5 58.7<br />

5.89 10.5 16.4 23.6 32.0 41.9 53.0 65.5<br />

6.44 11.4 17.9 25.7 35.0 45.8 57.9 71.5<br />

6.93 12.3 19.3 27.7 37.8 49.3 62.4 77.0<br />

7.39 13.1 20.5 29.6 40.3 52.6 66.6 82.2<br />

7.82 13.9 21.7 31.3 42.6 55.6 70.4 86.9<br />

8.23 14.6 22.9 32.9 44.8 58.5 74.0 91.4<br />

10.0 17.8 27.8 40.1 54.6 71.3 90.2 111<br />

11.8 21.0 32.8 47.2 64.2 83.9 106 131<br />

13.6 24.1 37.7 54.2 73.8 96.4 122 151<br />

15.3 27.2 42.6 61.3 83.5 109 138 170<br />

18.9 33.5 52.4 75.4 103 134 170 210<br />

22.4 39.8 62.2 89.6 122 159 202 249<br />

31.2 55.5 86.8 125 170 222 281 347<br />

40.1 71.2 111 160 218 285 361 445<br />

48.9 86.9 136 196 266 348 440 543<br />

57.7 103 160 231 314 411 520 642<br />

66.6 118 - - - - - -<br />

75.4 134 - - - - - -<br />

84.3 150 - - - - - -<br />

93.1 165 - - - - - -<br />

102 181 - - - - - -<br />

111 197 - - - - - -<br />

128 228 - - - - - -<br />

146 260 - - - - - -<br />

164 291 - - - - - -<br />

- - - - - - - -<br />

- - - - - - - -<br />

Vacuum Support Factors Dial Type: to 9 psig (0.62 bar) Bar Type: 10psig (0.69 bar) - 22psig (1.52bar)<br />

SIZE1/23/411 1/2 2 3 4 6 8 10 12 14 16 18 20 24<br />

Dial Type---.56.57.60.62.58.60.60.60.60.60.60.60.60<br />

Bar Type--.70.80.80.80.80.80.80.80.80.80.80.80.80.80<br />

Sold By: G&W <strong>Industrial</strong> <strong>Sales</strong><br />

304-422-4755<br />

21.3<br />

30.2<br />

42.6<br />

52.1<br />

60.1<br />

73.4<br />

84.5<br />

94.3<br />

103<br />

111<br />

118<br />

125<br />

132<br />

160<br />

189<br />

217<br />

245<br />

302<br />

358<br />

500<br />

641<br />

783<br />

924<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

To be used for direct discharge to the atmosphere,<br />

disk <strong>in</strong>stallation eight diameters from vessel nozzle<br />

entry, length of discharge pipe 5 pipe diameters,<br />

nom<strong>in</strong>al diameter of <strong>in</strong>let and discharge pip<strong>in</strong>g the<br />

NPS designation of the device.<br />

mail@gw<strong>in</strong>dustrial.com