OVER

brochure-small-3

brochure-small-3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

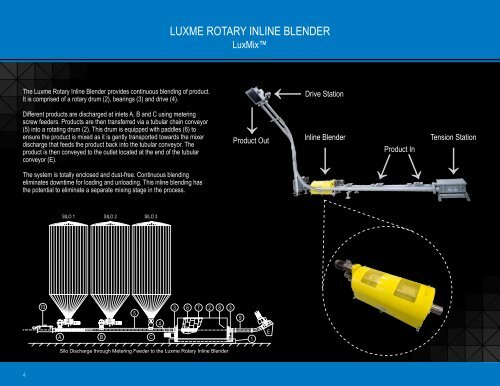

LUXME ROTARY INLINE BLENDER<br />

LuxMix<br />

The Luxme Rotary Inline Blender provides continuous blending of product.<br />

It is comprised of a rotary drum (2), bearings (3) and drive (4).<br />

←<br />

Drive Station<br />

Different products are discharged at inlets A, B and C using metering<br />

screw feeders. Products are then transferred via a tubular chain conveyor<br />

(5) into a rotating drum (2). This drum is equipped with paddles (6) to<br />

ensure the product is mixed as it is gently transported towards the mixer<br />

discharge that feeds the product back into the tubular conveyor. The<br />

product is then conveyed to the outlet located at the end of the tubular<br />

conveyor (E).<br />

The system is totally enclosed and dust-free. Continuous blending<br />

eliminates downtime for loading and unloading. This inline blending has<br />

the potential to eliminate a separate mixing stage in the process.<br />

←<br />

Product Out<br />

Inline Blender<br />

←<br />

←<br />

Product In<br />

←<br />

Tension Station<br />

←<br />

SILO 1<br />

SILO 2 SILO 3<br />

10<br />

A B C<br />

5<br />

4<br />

3<br />

6 7 2 8 3<br />

9<br />

1<br />

E<br />

Silo Discharge through Metering Feeder to the Luxme Rotary Inline Blender<br />

4