new heights

2eWZ7Uj

2eWZ7Uj

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WORLDWIDE HEAVY TRANSPORTATION AND LIFTING<br />

Case studies – Americas<br />

Case studies –<br />

Africa, Caspian and Middle East<br />

RECEIVING AND STORAGE OF 12 PIPE RACK<br />

MODULES, VENEZUELA<br />

OVERVIEW: ALE has successfully performed the receiving and storage of 12 pipe rack<br />

modules, weighing a total of 1,312.2t, for the Deep Conversion Project.<br />

SERVICES REQUIRED: The 12 modules ranged in weight and size, with some as heavy<br />

as 161.8t and measuring up to 32.1m long, 11.5m wide and 11m high.<br />

The modules were received from the vessel at the Port of Guanta, where they were<br />

prepared for onward transportation to the refinery.<br />

Two transport configurations were utilised, consisting of 32 axle lines of SPMT in a 4 file<br />

16 configuration and 40 axle lines of SPMT in a 4 file 20 configuration with two spacer beds.<br />

Overall, ALE has to date received 44 pipe rack modules out of the 96 for the Deep<br />

Conversion Project.<br />

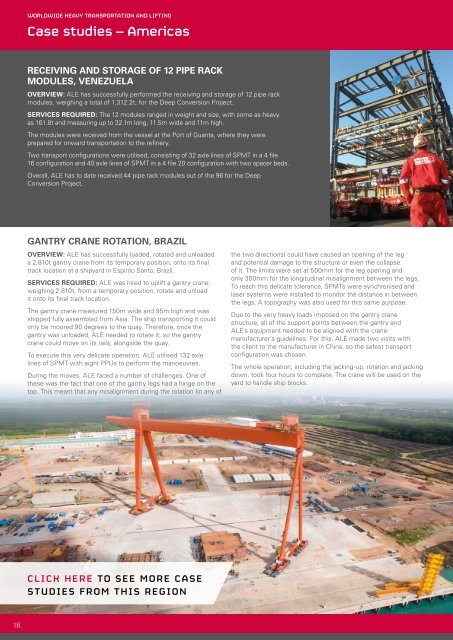

GANTRY CRANE ROTATION, BRAZIL<br />

OVERVIEW: ALE has successfully loaded, rotated and unloaded<br />

a 2,810t gantry crane from its temporary position, onto its final<br />

track location at a shipyard in Espírito Santo, Brazil.<br />

SERVICES REQUIRED: ALE was hired to uplift a gantry crane,<br />

weighing 2,810t, from a temporary position, rotate and unload<br />

it onto its final track location.<br />

The gantry crane measured 150m wide and 95m high and was<br />

shipped fully assembled from Asia. The ship transporting it could<br />

only be moored 90 degrees to the quay. Therefore, once the<br />

gantry was unloaded, ALE needed to rotate it, so the gantry<br />

crane could move on its rails, alongside the quay.<br />

To execute this very delicate operation, ALE utilised 132 axle<br />

lines of SPMT with eight PPUs to perform the manoeuvres.<br />

During the moves, ALE faced a number of challenges. One of<br />

these was the fact that one of the gantry legs had a hinge on the<br />

top. This meant that any misalignment during the rotation (in any of<br />

CLICK HERE TO SEE MORE CASE<br />

STUDIES FROM THIS REGION<br />

the two directions) could have caused an opening of the leg<br />

and potential damage to the structure or even the collapse<br />

of it. The limits were set at 500mm for the leg opening and<br />

only 300mm for the longitudinal misalignment between the legs.<br />

To reach this delicate tolerance, SPMTs were synchronised and<br />

laser systems were installed to monitor the distance in between<br />

the legs. A topography was also used for this same purpose.<br />

Due to the very heavy loads imposed on the gantry crane<br />

structure, all of the support points between the gantry and<br />

ALE´s equipment needed to be aligned with the crane<br />

manufacturer’s guidelines. For this, ALE made two visits with<br />

the client to the manufacturer in China, so the safest transport<br />

configuration was chosen.<br />

The whole operation, including the jacking-up, rotation and jacking<br />

down, took four hours to complete. The crane will be used on the<br />

yard to handle ship blocks.<br />

TRANSPORTATION AND INSTALLATION OF HEAVY CARGO TO TWO COMBINED-CYCLE<br />

POWER PLANTS, EGYPT<br />

OVERVIEW: ALE has been awarded the transportation and<br />

installation scope for the largest combined cycle project in<br />

the world.<br />

ALE has successfully completed the first stage, involving the<br />

transportation and installation of heavy mechanical equipment to<br />

the <strong>new</strong>ly constructed gas combined-cycle power plants in Beni<br />

Suef and New Capital, Egypt.<br />

SERVICES REQUIRED: In the short period of 10 weeks, ALE has<br />

transported six gas turbines, six generators and two transformers<br />

to the power plant in Beni Suef, installing all of the turbines and<br />

generators. Simultaneously, ALE has transported one transformer,<br />

two generators and two turbines to New Capital, also installing all of<br />

the turbines and generators.<br />

Because of the challenging slopes and roads ALE faced during the<br />

route, it needed up to three prime movers to carry the<br />

heaviest gas turbines.<br />

WEIGHING, TRANSPORTATION AND LOAD-OUT OF TWO JACKETS, QATAR<br />

OVERVIEW: ALE has successfully completed the weighing, transportation and load-out of two jackets in Ras Laffan, Qatar.<br />

SERVICES REQUIRED:<br />

Both jackets were weighed using<br />

eight 600t weightors. The jackets<br />

weighed 2,628t and 2,581t and<br />

measured 57.04m long x 35m<br />

wide x 36.80m high, making these<br />

jackets the largest and heaviest<br />

jacket to ever be fabricated in Qatar.<br />

ALE transported the jackets<br />

from the fabrication yard to the<br />

quayside. ALE used 144 axle lines<br />

of Gen 3 SPMTs in a 6 x 2 file 24<br />

configuration.<br />

In consideration of the site<br />

restrictions and the limitations set<br />

by the semi-submersible barge, a<br />

side load-out was performed on<br />

the barge to enable the jacket to<br />

float-off once offshore.<br />

The load-out operation was fully<br />

controlled by a self-ballasting<br />

system of the semi-submersible<br />

barge. Each load-out operation<br />

took approximately three hours<br />

to complete.<br />

ALE’s award-winning Trojan truck and an MAN truck are being used<br />

on the project, reducing the amount of prime movers,<br />

from three to two.<br />

The gas turbines and generators were installed using skidding<br />

gantries and were moved inside the plant using<br />

24 axle lines of SPMT in a 4 file 12 configuration.<br />

This is part of a bigger contract, where each power plant will have<br />

the power of 4,800 MW, separated in eight gas blocks<br />

and four steam blocks. The total heavy cargo ALE has been<br />

contracted to deliver comprises of: 16 gas turbines weighing<br />

486t and the corresponding generators, eight steam generators,<br />

transformers and more than 380 boiler modules.<br />

The cargo was first delivered to Beni Suef power plant and then to<br />

New Capital power plant two months later. So far,<br />

ALE has not only fulfilled the intended plan but has also managed<br />

to shorten the transportation time of this project.<br />

18. CLICK HERE TO SEE MORE CASE STUDIES FROM THIS REGION<br />

19.