SHEQWs Newsletter November

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

In the spotlight<br />

Tunnel Inspections - Walthamstow<br />

Overview<br />

In early <strong>November</strong> the team mobilised in Walthamstow<br />

fishery’s to undertake various tunnel inspections.<br />

The first was tunnel was only a few hundred meters long<br />

and was in good order with next to no mussel or silt inside.<br />

Following on from this a compound was set up in the<br />

Lockwood compound opposite the main fisheries, to allow<br />

for works to the second tunnel , which spanned 6km to<br />

begin. Shortly after the spine tunnel was started which<br />

runs from the break pressure tank just south of the William<br />

Girling Reservoir to Coppermills Water Treatment Works.<br />

Preparing for the tunnel cleaning<br />

Once the permits were acquired by eight20 from Thames<br />

Water, the survey was undertaken. With all the lift plans,<br />

isolation procedure and RAMS in places.<br />

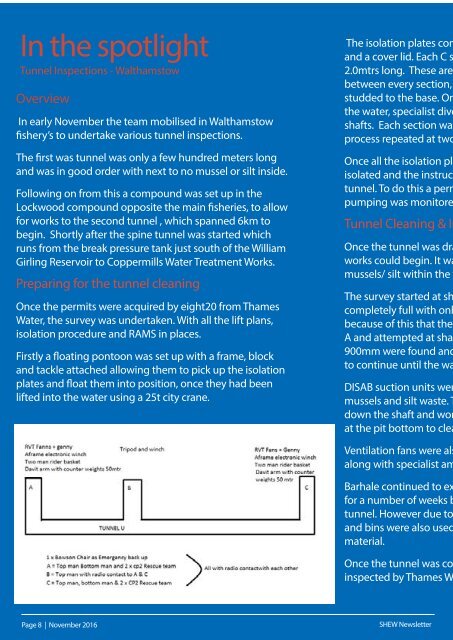

Firstly a floating pontoon was set up with a frame, block<br />

and tackle attached allowing them to pick up the isolation<br />

plates and float them into position, once they had been<br />

lifted into the water using a 25t city crane.<br />

The isolation plates consisted of three C section plates<br />

and a cover lid. Each C section is approx. 1mtr high and<br />

2.0mtrs long. These are all bolted together with gaskets<br />

between every section, along the head wall and then<br />

studded to the base. Once the isolation plates were in<br />

the water, specialist divers were bought in to survey the<br />

shafts. Each section was installed until completed and the<br />

process repeated at two locations shaft A & C.<br />

Once all the isolation plates were installed, the tunnel was<br />

isolated and the instruction was given to drain down the<br />

tunnel. To do this a permits to pump was raised and the<br />

pumping was monitored until the tunnel was empty.<br />

Tunnel Cleaning & Inspection<br />

Once the tunnel was drained, the survey phase of the<br />

works could begin. It was at this stage that the amount of<br />

mussels/ silt within the tunnel was apparent.<br />

The survey started at shaft A where the tunnel was almost<br />

completely full with only 300mm gap to crown. It was<br />

because of this that the survey was abandoned at shaft<br />

A and attempted at shaft C where debris depths of 8 to<br />

900mm were found and so the survey was deemed unsafe<br />

to continue until the waste had been removed.<br />

DISAB suction units were then employed to extract the<br />

mussels and silt waste. This involved connecting 6”hoses<br />

down the shaft and working from the main riding basket<br />

at the pit bottom to clear the way into the tunnel.<br />

Ventilation fans were also installed to purge the tunnel<br />

along with specialist ammonia gas detectors.<br />

Barhale continued to extract waste and clear the tunnel<br />

for a number of weeks by extending the hose into the<br />

tunnel. However due to the amount of build-up, trollies<br />

and bins were also used as a much faster way to move the<br />

material.<br />

Once the tunnel was completely cleaned it was then<br />

inspected by Thames Water and eight20.<br />

Page 8 | <strong>November</strong> 2016 SHEW <strong>Newsletter</strong><br />

SHEW <strong>Newsletter</strong><br />

<strong>November</strong> 2016 | Page 9