Wood Finishes

Knowledge and Advice

Knowledge and Advice

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

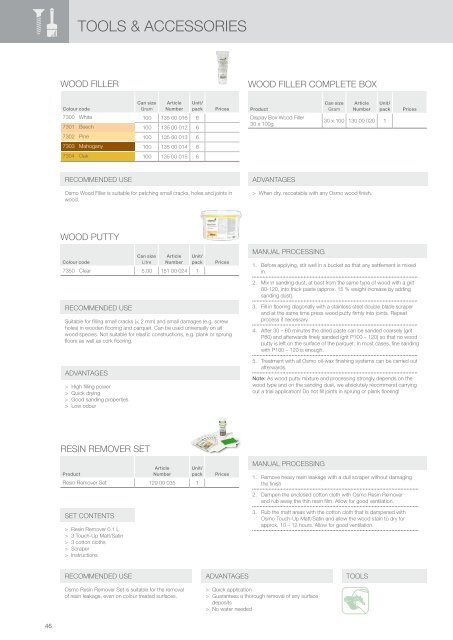

TOOLS & ACCESSORIES<br />

WOOD FILLER<br />

WOOD FILLER COMPLETE BOX<br />

Colour code<br />

7300 White<br />

7301 Beech<br />

Can size<br />

Gram<br />

Article<br />

Number<br />

Unit/<br />

pack<br />

100 13500016 6<br />

100 13500012 6<br />

Prices<br />

Product<br />

Display Box <strong>Wood</strong> Filler<br />

30 x 100g<br />

Can size<br />

Gram<br />

Article<br />

Number<br />

Unit/<br />

pack<br />

30 x 100 13000020 1<br />

Prices<br />

7302 Pine<br />

100 13500013 6<br />

7303 Mahogany<br />

100 13500014 6<br />

7304 Oak<br />

100 13500015 6<br />

RECOMMENDED USE<br />

ADVANTAGES<br />

Osmo <strong>Wood</strong> Filler is suitable for patching small cracks, holes and joints in<br />

wood.<br />

> > When dry, recoatable with any Osmo wood finish.<br />

WOOD PUTTY<br />

Colour code<br />

7350 Clear<br />

Can size<br />

Litre<br />

Article<br />

Number<br />

Unit/<br />

pack<br />

5.00 15100024 1<br />

Prices<br />

MANUAL PROCESSING<br />

1. Before applying, stir well in a bucket so that any settlement is mixed<br />

in.<br />

2. Mix in sanding dust, at best from the same type of wood with a grit<br />

80-120, into thick paste (approx. 15 % weight increase by adding<br />

sanding dust).<br />

RECOMMENDED USE<br />

Suitable for filling small cracks (< 2 mm) and small damages (e.g. screw<br />

holes) in wooden flooring and parquet. Can be used universally on all<br />

wood species. Not suitable for elastic constructions, e.g. plank or sprung<br />

floors as well as cork flooring.<br />

ADVANTAGES<br />

> > High filling power<br />

> > Quick drying<br />

> > Good sanding properties<br />

> > Low odour<br />

3. Fill in flooring diagonally with a stainless steel double blade scraper<br />

and at the same time press wood putty firmly into joints. Repeat<br />

process if necessary.<br />

4. After 30 – 60 minutes the dried paste can be sanded coarsely (grit<br />

P80) and afterwards finely sanded (grit P100 – 120) so that no wood<br />

putty is left on the surface of the parquet. In most cases, fine sanding<br />

with P100 – 120 is enough.<br />

5. Treatment with all Osmo oil-wax finishing systems can be carried out<br />

afterwards.<br />

Note: As wood putty mixture and processing strongly depends on the<br />

wood type and on the sanding dust, we absolutely recommend carrying<br />

out a trial application! Do not fill joints in sprung or plank flooring!<br />

RESIN REMOVER SET<br />

Article Unit/<br />

Product<br />

Number pack<br />

Resin Remover Set 12900035 1<br />

SET CONTENTS<br />

> > Resin Remover 0.1 L<br />

> > 3 Touch-Up Matt/Satin<br />

> > 3 cotton cloths<br />

> > Scraper<br />

> > Instructions<br />

Prices<br />

MANUAL PROCESSING<br />

1. Remove heavy resin leakage with a dull scraper without damaging<br />

the finish<br />

2. Dampen the enclosed cotton cloth with Osmo Resin Remover<br />

and rub away the thin resin film. Allow for good ventilation.<br />

3. Rub the matt areas with the cotton cloth that is dampened with<br />

Osmo Touch-Up Matt/Satin and allow the wood stain to dry for<br />

approx. 10 – 12 hours. Allow for good ventilation.<br />

RECOMMENDED USE<br />

ADVANTAGES<br />

TOOLS<br />

Osmo Resin Remover Set is suitable for the removal<br />

of resin leakage, even on colour treated surfaces.<br />

> > Quick application<br />

> > Guarantees a thorough removal of any surface<br />

deposits<br />

> > No water needed<br />

46