CHIRP annual digest 2016 flip

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>CHIRP</strong> Maritime<br />

blanks were located at the manifold. The necessary<br />

replacement components were fitted in due course.<br />

Lessons to be learnt<br />

The company was correctly concerned with this report. It<br />

emerged that there had been no previous order for a new<br />

valve, no record or explanation of the blanks, and no<br />

discussion at the time with the company office or at ship<br />

staff handover.<br />

<strong>CHIRP</strong> Suggests<br />

The company took admirable steps to emphasise the<br />

importance of timely and open ship/shore dialogue.<br />

Frequent communication between the office super -<br />

intendent(s) and the vessel can assist with this. In the first<br />

instance a material defect was concealed, and not rectified,<br />

with potentially severe consequences: pollution, injury,<br />

and/or pipeline damage. We may surmise, but cannot<br />

know, the original reasons. The case is a clear illustration<br />

of poor prevalent safety culture at the time.<br />

The above article was published in MFB44<br />

Article. 41<br />

Ouch! – Bad Ship Designs<br />

We encourage seafarers to submit examples of bad design.<br />

Please include photographs, since a picture speaks a<br />

thousand words! We can share two such reports with you<br />

here.<br />

What did the reporter tell us?<br />

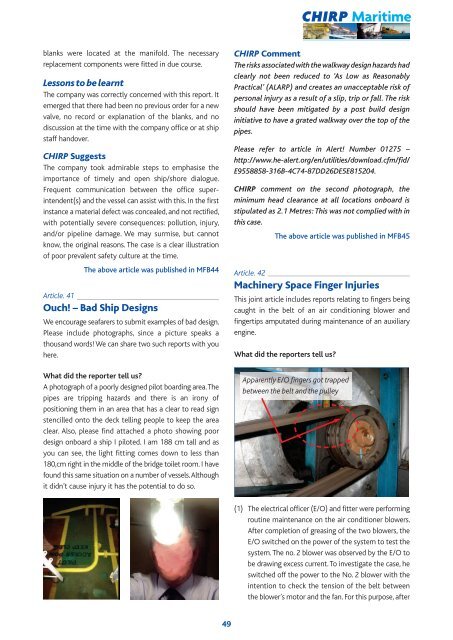

A photograph of a poorly designed pilot boarding area. The<br />

pipes are tripping hazards and there is an irony of<br />

positioning them in an area that has a clear to read sign<br />

stencilled onto the deck telling people to keep the area<br />

clear. Also, please find attached a photo showing poor<br />

design onboard a ship I piloted. I am 188 cm tall and as<br />

you can see, the light fitting comes down to less than<br />

180,cm right in the middle of the bridge toilet room. I have<br />

found this same situation on a number of vessels. Although<br />

it didn’t cause injury it has the potential to do so.<br />

<strong>CHIRP</strong> Comment<br />

The risks associated with the walkway design hazards had<br />

clearly not been reduced to ‘As Low as Reasonably<br />

Practical’ (ALARP) and creates an unacceptable risk of<br />

personal injury as a result of a slip, trip or fall. The risk<br />

should have been mitigated by a post build design<br />

initiative to have a grated walkway over the top of the<br />

pipes.<br />

Please refer to article in Alert! Number 01275 –<br />

http://www.he-alert.org/en/utilities/download.cfm/fid/<br />

E9558858-316B-4C74-87DD26DE5E815204.<br />

<strong>CHIRP</strong> comment on the second photograph, the<br />

minimum head clearance at all locations onboard is<br />

stipulated as 2.1 Metres: This was not complied with in<br />

this case.<br />

The above article was published in MFB45<br />

Article. 42<br />

Machinery Space Finger Injuries<br />

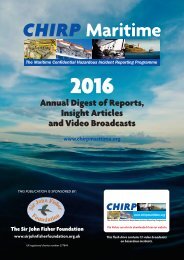

This joint article includes reports relating to fingers being<br />

caught in the belt of an air conditioning blower and<br />

fingertips amputated during maintenance of an auxiliary<br />

engine.<br />

What did the reporters tell us?<br />

Apparently E/O fingers got trapped<br />

between the belt and the pulley<br />

(1) The electrical officer (E/O) and fitter were performing<br />

routine maintenance on the air conditioner blowers.<br />

After completion of greasing of the two blowers, the<br />

E/O switched on the power of the system to test the<br />

system. The no. 2 blower was observed by the E/O to<br />

be drawing excess current. To investigate the case, he<br />

switched off the power to the No. 2 blower with the<br />

intention to check the tension of the belt between<br />

the blower’s motor and the fan. For this purpose, after<br />

49