FORWARD

2jGsAEn

2jGsAEn

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE<br />

DIGITAL TWIN<br />

With the rise of digital, manufacturers are finding themselves rich in data. Meanwhile,<br />

computing has emerged as the cheapest, most abundant resource that we can deploy<br />

against any problem.<br />

The problem in manufacturing is not the lack of new ideas and products, but the ability<br />

to design and build new products efficiently. An IDC Big Data user study found that<br />

operations-related processes were the top priority for analytics investments.<br />

This next wave of IT innovation, the rise of digital, is providing manufacturing with<br />

the engine to improve efficiency. IT has become an integral part of a product. This<br />

is because of cheap sensors and processors, cheap storage, purpose-built software,<br />

purpose-built clouds enabling data storage and ubiquitous connectivity.<br />

Simulating new innovations is the idea behind the digital twin in manufacturing. We can<br />

use stochastic simulation to generate future “what-if” scenarios and use those scenarios<br />

to avoid costly product quality issues, speed time to market, and increase throughput.<br />

This may sound exotic, but it is really just a modern twist on a very old idea — the<br />

scientific method. Build stochastic simulations, generate experiments, and use those<br />

experiments to minimize risk and innovate in the process.<br />

Tesla is an excellent example of this concept. Tesla has a digital twin of every VIN they<br />

manufacture. Data is constantly being transmitted back and forth from the car to the<br />

factory. If a driver has a rattle in a door, it can be fixed by downloading software to adjust<br />

the hydraulics of that particular door. Tesla regularly downloads software updates to<br />

their customers’ cars based on the data they are constantly receiving from each VIN.<br />

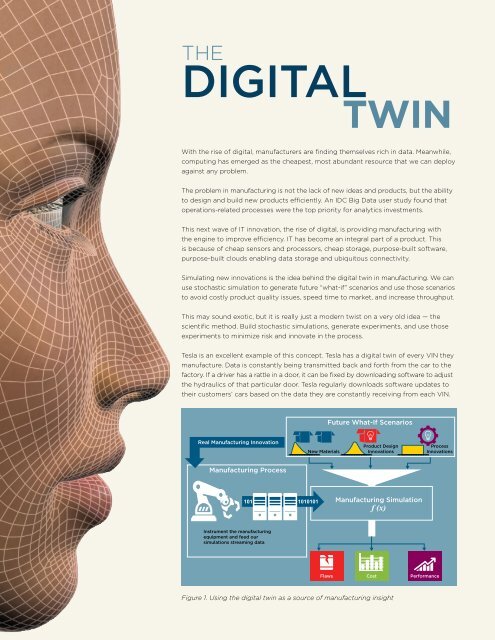

Future What-If Scenarios<br />

Real Manufacturing Innovation<br />

New Materials<br />

Product Design<br />

Innovations<br />

Process<br />

Innovations<br />

Manufacturing Process<br />

101 1010101<br />

Manufacturing Simulation<br />

f (x)<br />

Instrument the manufacturing<br />

equipment and feed our<br />

simulations streaming data<br />

Flaws<br />

Cost<br />

Performance<br />

Figure 1. Using the digital twin as a source of manufacturing insight<br />

10 <strong>FORWARD</strong>: A CSC MAGAZINE