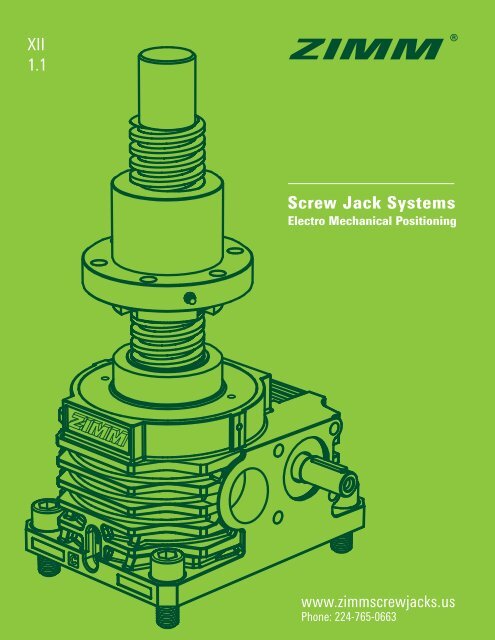

ZIMM US_Screw Jack Systems_Brochure Xll1.1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

XII<br />

1.1<br />

<strong>Screw</strong> <strong>Jack</strong> <strong>Systems</strong><br />

Electro Mechanical Positioning<br />

www.zimmscrewjacks.us<br />

Phone: 224-765-0663

PROGRAM, MARKET SEGMENTS<br />

Program benefits<br />

• Precision acme and ball screws<br />

• Translating and Rotating version<br />

• Multiple spindle end connections<br />

• Mutliple driving nut designs<br />

• Modular housing for mounting versatility<br />

• Mutliple safety and protection options<br />

• Motion control options<br />

• Complete system designs<br />

Market segments<br />

• Aerospace<br />

• Packaging<br />

• Automotive<br />

• Electronics<br />

• Transportation<br />

• Semiconductor<br />

• Military and defense<br />

• Factory automation<br />

• Pulp and paper<br />

• Steel<br />

• Chemical<br />

• Medical and diagnostic

APPLICATION EXAMPLES<br />

<strong>Screw</strong> jack application<br />

Translating lift<br />

for pallets<br />

Adjustment system<br />

for bearings in the<br />

textile industry<br />

Parabolic antenna D = 3.3 m,<br />

both axes – azimuth + elevation<br />

– each 50 kN, travel for<br />

each movement 0.02 - 0.05<br />

mm; system installed in the<br />

open air on the coast<br />

Centring mechanism<br />

using right and left<br />

threaded screws<br />

Pivoting conveyor<br />

system<br />

Metering slide<br />

in a grain chute<br />

PA<br />

P<br />

ATENT<br />

Patent<br />

pending<br />

We have patents registered or pending for a range of functions and components.<br />

P E N D I N G<br />

Opening and closing<br />

a container<br />

Scissor lift table<br />

1

PRODUCT OVERVIEW<br />

Z series – features<br />

When should I use a Z series screw jack?<br />

Z series screw jacks are the preferred range with the<br />

largest number of types. The Z series feature through<br />

holes for top mounting and integral pivot bearings,<br />

features not available on the GSZ series.<br />

Pivot bearing<br />

Top mounting<br />

1<br />

Variant:<br />

Trapezoidal<br />

screw<br />

Tr<br />

Variant:<br />

Safety nut<br />

SIFA<br />

Variant:<br />

Ball screw<br />

KGT<br />

9<br />

10<br />

2<br />

1. 1. 1.<br />

8<br />

Corrosion<br />

resistant<br />

Highperformance<br />

hardened and<br />

ground gears<br />

Standard flange,<br />

simple and<br />

costeffective<br />

9<br />

6<br />

7<br />

5<br />

4<br />

3<br />

2. 3. 4.<br />

Side marking<br />

Direct screw<br />

lubrication<br />

Fluid grease<br />

in the gearbox<br />

permits high<br />

performance<br />

5. 6. 7.<br />

Integrated<br />

pivot bearing<br />

Four mounting<br />

options<br />

Sealed gearbox<br />

8. 9. 10.<br />

2

PRODUCT OVERVIEW<br />

GSZ series – features<br />

When should I use a GSZ series screw jack?<br />

GSZ series screw jacks are designed for applications<br />

where smooth surfaces are required. These screw jacks<br />

are easier to clean.<br />

Smooth surface<br />

1<br />

Variant:<br />

Trapezoidal<br />

screw<br />

Tr<br />

Variant:<br />

Safety nut<br />

SIFA<br />

Variant:<br />

Ball screw<br />

KGT<br />

8<br />

9<br />

10<br />

2<br />

3<br />

1. 1. 1.<br />

Corrosion<br />

resistant<br />

Smooth,<br />

easy-to-clean<br />

surface<br />

Highperformance<br />

hardened and<br />

ground gears<br />

8<br />

6<br />

7<br />

5<br />

4<br />

2. 3. 4.<br />

Standard flange,<br />

simple and<br />

costeffective<br />

Direct screw<br />

lubrication<br />

Fluid grease<br />

in the gearbox<br />

permits high<br />

performance<br />

5.<br />

6. 7.<br />

Top or bottom<br />

mounting<br />

Sealed gearbox<br />

Optional stainless<br />

steel screw<br />

PA<br />

P<br />

ATENT<br />

Patent<br />

pending<br />

We have patents registered or pending for a range of functions and components.<br />

P E N D I N G<br />

8. 9. 10.<br />

3

PRODUCT OVERVIEW<br />

Sizes – Types<br />

Z<br />

series<br />

Load 5 kN 10 kN 25 kN 35 kN 50 kN 100 kN<br />

S translating screw<br />

R rotating screw<br />

Drive ratios<br />

Housing material<br />

Z-Tr<br />

with trapezoidal screw<br />

Z-KGT<br />

with ball screw<br />

Z-SIFA<br />

with safety nut<br />

S<br />

Version<br />

R<br />

Version<br />

i= 4:1 i= 4:1 i= 6:1 i= 7:1 i= 7:1 i= 9:1<br />

i= 16:1 i= 16:1 i= 24:1 i= 28:1 i= 28:1 i= 36:1<br />

Aluminium Aluminium Aluminium GGG-50 GGG-50 GGG-50<br />

18x4 18x4 20x4 20x4 30x6 30x6 40x7 40x7 40x7<br />

50x8<br />

16x5<br />

16x10<br />

16x5<br />

16x10<br />

S<br />

Version<br />

25x5<br />

25x10<br />

25x25<br />

25x50<br />

R<br />

Version<br />

25x5<br />

25x10<br />

25x25<br />

25x50<br />

<strong>Screw</strong> versions: increased / double-pitch / left-handed / stainless steel<br />

S<br />

Version<br />

32x5<br />

32x10<br />

32x20<br />

32x40<br />

R<br />

Version<br />

32x5<br />

32x10<br />

32x20<br />

32x40<br />

S<br />

Version<br />

R<br />

Version<br />

40x5<br />

40x10<br />

40x20<br />

40x40<br />

S<br />

Version<br />

40x5<br />

40x10<br />

40x20<br />

40x40<br />

R<br />

Version<br />

40x7 55x9 55x9<br />

40x5<br />

40x10<br />

40x20<br />

40x40<br />

S<br />

Version<br />

50x10<br />

50x20<br />

50x40<br />

R<br />

Version<br />

50x10<br />

50x20<br />

50x40<br />

50x50<br />

18x4 20x4 20x4 30x6 30x6 40x7 40x7 40x7 40x7 55x9 55x9<br />

GSZ<br />

series<br />

Load 2.5 kN 5 kN 10 kN 25 kN 50 kN 100 kN<br />

S translating screw<br />

R rotating screw<br />

Drive ratios<br />

Housing material<br />

GSZ-Tr<br />

with trapezoidal screw<br />

GSZ-KGT<br />

with ball screw<br />

GSZ-SIFA<br />

with safety nut<br />

S<br />

Version<br />

i= 4:1 i= 4:1 i= 4:1 i= 6:1<br />

i= 7:1 i= 9:1<br />

i= 16:1 i= 16:1 i= 16:1 i= 24:1<br />

i= 28:1 i= 36:1<br />

Aluminium Aluminium Aluminium Aluminium GGG-50 GGG-50<br />

16x4<br />

R<br />

Version<br />

16x4<br />

16x5<br />

16x10<br />

S<br />

Version<br />

18x4<br />

16x5<br />

16x10<br />

R<br />

Version<br />

18x4<br />

16x5<br />

16x10<br />

S<br />

Version<br />

20x4<br />

25x5<br />

25x10<br />

25x25<br />

25x50<br />

R<br />

Version<br />

20x4<br />

25x5<br />

25x10<br />

25x25<br />

25x50<br />

S<br />

Version<br />

30x6<br />

32x5<br />

32x10<br />

32x20<br />

32x40<br />

R<br />

Version<br />

30x6<br />

32x5<br />

32x10<br />

32x20<br />

32x40<br />

S<br />

Version<br />

40x7<br />

40x5<br />

40x10<br />

40x20<br />

40x40<br />

R<br />

Version<br />

40x7<br />

40x5<br />

40x10<br />

40x20<br />

40x40<br />

S<br />

Version<br />

55x9<br />

50x10<br />

50x20<br />

50x40<br />

R<br />

Version<br />

55x9<br />

50x10<br />

50x20<br />

50x40<br />

50x50<br />

16x4 18x4 20x4 20x4 30x6 30x6 40x7 40x7 55x9 55x9<br />

<strong>Screw</strong> versions: increased / double-pitch / left-handed / stainless steel<br />

4

PRODUCT OVERVIEW<br />

150 kN 250 kN 350 kN 500 kN 750 kN 1000 kN<br />

S<br />

Version<br />

R<br />

Version<br />

S<br />

Version<br />

R<br />

Version<br />

S<br />

Version<br />

R<br />

Version<br />

S<br />

Version<br />

R<br />

Version<br />

S<br />

Version<br />

R<br />

Version<br />

S<br />

Version<br />

i= 9:1<br />

i= 10.66:1<br />

i= 10.66:1<br />

i= 10.66:1<br />

i= 13.33:1<br />

i= 13.33:1<br />

i= 36:1<br />

i= 32:1<br />

i= 32:1<br />

i= 32:1<br />

i= 40:1<br />

i= 40:1<br />

GGG-50 GGG-50 GGG-50 GGG-50 GGG-50 GGG-50<br />

R<br />

Version<br />

60x9 60x9 80x16 80x16 100x16 100x16 120x16 120x16 140x20 140x20 160x20 160x20<br />

63x10<br />

63x20<br />

63x40<br />

63x60<br />

63x10<br />

63x20<br />

63x40<br />

63x60<br />

80x10<br />

80x20<br />

80x40<br />

80x60<br />

80x10<br />

80x20<br />

80x40<br />

80x60<br />

100x20<br />

100x40<br />

100x60<br />

100x80<br />

100x20<br />

100x40<br />

100x60<br />

100x80<br />

125x25<br />

125x40<br />

125x60<br />

125x80<br />

125x25<br />

125x40<br />

125x60<br />

125x80<br />

140x25<br />

140x40<br />

140x60<br />

140x80<br />

140x25<br />

140x40<br />

140x60<br />

140x80<br />

160x25<br />

160x40<br />

160x60<br />

160x80<br />

160x25<br />

160x40<br />

160x60<br />

160x80<br />

60x9 60x9 80x16 80x16 100x16 100x16 120x16 120x16 140x20 140x20 160x20 160x20<br />

CAD<br />

Product configurator<br />

The <strong>ZIMM</strong> CAD configurator on our website<br />

can be used to quickly select and prepare<br />

design data.<br />

www.zimmscrewjacks.us<br />

PA<br />

P<br />

ATENT<br />

Patent<br />

pending<br />

We have patents registered or pending for a range of functions and components.<br />

P E N D I N G<br />

5

PRODUCT OVERVIEW<br />

S version<br />

Translating screw<br />

<strong>Screw</strong> jack versions<br />

Trapezoidal screw<br />

Tr<br />

Ball screw<br />

KGT<br />

Safety nut<br />

SIFA<br />

6

PRODUCT OVERVIEW<br />

R version<br />

Rotating screw<br />

PA<br />

P<br />

ATENT<br />

Patent<br />

pending<br />

We have patents registered or pending for a range of functions and components.<br />

P E N D I N G<br />

7

CHECKLIST<br />

Sheet 1 - Parameters<br />

Company:<br />

Address:<br />

Contact:<br />

Dept.:<br />

Date:<br />

Phone:<br />

Fax:<br />

Email:<br />

1. max. lifting force in kN<br />

- per gearbox ________ kN for the entire system ________ kN<br />

- in tension ________ kN in compression ________ kN<br />

- Load: static ________ kN dynamic ________ kN<br />

Installation axis<br />

c vertical c horizontal c pivoting<br />

Type of load<br />

c smooth c impact loads c vibration<br />

2. max. lift/ travel ________ mm c effective working stroke ___________ mm<br />

For short stroke applications<br />

(eff. working stroke < gearbox height): c regular lubrication stroke practical c not practical<br />

3. Lifting speed<br />

c type N = 25 mm/s (1.5 m/min) c type L = 6.25 mm/s (0.375 m/min) c ___________________ mm/s<br />

4. Duty factor, work cycle, description of cycle<br />

__________ strokes per hour __________ strokes per day Hours per day c 8 c 16 c 24<br />

For high duty factors or long strokes, please provide an exact detailed description on page 9, 4a<br />

5. Type c S “Translating screw” c R “Rotating screw” c Z screw jack c GSZ screw jack<br />

6. Motor c Three-phase AC motor c With brake c Manual release c ________________________<br />

7. Operating conditions: c Dry c Humid c Dust c Chipping c ________________________<br />

c Guided movement<br />

c No guides (no dyn. lateral forces)<br />

Ambient temperature: min. ___________ °C max. ___________ °C (when 40°C)<br />

If possible please provide an exact description or sketch on page 9, 7a<br />

8. Standard layouts no.: ______________ Size: MA1 __________ MA2 __________ MA3 __________ MA4 __________ MA5 __________<br />

see standard layouts, checklist sheets 5 and 6 (for multi-jack systems)<br />

9. Quantity Required: ______________________________________ Series: ___________________________________________<br />

10. Schedule Quotation: ______________________________________ Delivery: ___________________________________________<br />

8

CHECKLIST<br />

Sheet 2 (optional)<br />

4a. Duty factor, work cycle, description of cycle<br />

Duty cycle diagram:<br />

Retraction Extension<br />

7a. Purpose / description of the function / ambient conditions (description or sketch)<br />

Example:<br />

5s break<br />

10s up<br />

5s down<br />

5s break<br />

5s down<br />

1 cycle 90s<br />

60s break<br />

Time<br />

9

CHECKLIST<br />

Sheet 3 - List of components S<br />

Type:<br />

c SN (Translating screw, normal)<br />

c SL (Translating screw, low speed)<br />

Variant:<br />

c Tr screw<br />

c SIFA safety nut<br />

c with SIFA monitoring<br />

c KGT ball screw<br />

1. Tension load (kN): static<br />

Tension load (kN): dynamic<br />

2. Compression load (kN): static<br />

1<br />

Compression load (kN): dynamic<br />

Stroke<br />

16<br />

3<br />

17<br />

2<br />

15<br />

4<br />

14<br />

5<br />

13<br />

6<br />

12<br />

11<br />

7<br />

10<br />

9<br />

8<br />

3. Standard screw end c<br />

4. Fixing flange BF c<br />

5. Bellows FB c<br />

Spiral spring SF c<br />

6. Rod end KGK c<br />

7. Forked end GK c<br />

8. Pivot bearing end SLK c<br />

9. Handwheel HR c<br />

10. Motor with brake c<br />

Motor without brake c<br />

11. Motor flange MF c<br />

12. Pivot mounts LB c<br />

13. Coupling KUZ c<br />

14. Pivot bearing plate KAR c<br />

15. Lubricator Z-LUB c<br />

16. Protective cap SK c<br />

17. Lubrication strip SL c<br />

18. Rotation protection VS c<br />

Escape protection AS c<br />

19. 2x limit switch ES c<br />

20. Protective tube SRO c<br />

Pivoting support tube STRO c<br />

18<br />

19<br />

20<br />

10

CHECKLIST<br />

Sheet 4 - List of components R<br />

Type:<br />

c RN (Rotating screw, normal)<br />

c RL (Rotating screw, low speed)<br />

Variant:<br />

c Tr screw<br />

c SIFA safety nut<br />

c with SIFA monitoring<br />

c KGT ball screw<br />

1<br />

2<br />

3 4 5<br />

1. Tension load (kN): static<br />

Tension load (kN): dynamic<br />

2. Compression load (kN): static<br />

Compression load (kN): dynamic<br />

Stroke<br />

14<br />

13<br />

6<br />

7 8<br />

9<br />

11<br />

10<br />

12<br />

3. Opposed bearing plate GLP c<br />

4. Bellows FB c<br />

5. Spiral spring cover SF c<br />

6. Lubricator Z-LUB c<br />

7. Duplex nut DM c<br />

Tr flange nut FM c<br />

Cardan adapter DMA c<br />

KGT flange nut KGT-F c<br />

Self-aligning nut PM c<br />

Greaseless nut FFDM c<br />

Driving flange TRMFL c<br />

Safety nut SIFA<br />

c<br />

Wear monitoring SIFA Control c<br />

8. Handwheel HR c<br />

9. Motor with brake c<br />

Motor without brake c<br />

10. Motor flange MF c<br />

11. Coupling KUZ c<br />

12. Pivot mounts LB c<br />

13. Pivot bearing plate KAR c<br />

14. Protective cap SK c<br />

11

CHECKLIST<br />

Sheet 5 - System layouts<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

The most common layouts are shown. If your design is different, be sure to check the direction of rotation!<br />

12

CHECKLIST<br />

Sheet 6 - System layouts<br />

I<br />

J<br />

K<br />

L<br />

M<br />

N<br />

The most common layouts are shown. If your design is different, be sure to check the direction of rotation!<br />

13

ABOUT <strong>ZIMM</strong><br />

<strong>ZIMM</strong> Maschinenelemente GmbH + Co KG is an international<br />

family-owned enterprise specialising in manufacturing of<br />

screw jack systems and transmission parts.<br />

The screw jack building block system offers a flexible<br />

programme for the precise electromechanical adjustment<br />

of linear movements and with loads weighing as much as<br />

100 tons (1000 kN) per screw jack.<br />

<strong>ZIMM</strong>‘s product portfolio also includes a wide range of<br />

transmission parts for screw, connecting, gear, and linear<br />

technology.<br />

The headquarters is located in Lustenau, Vorarlberg (Austria).<br />

<strong>ZIMM</strong> has over 30 representatives around the world.<br />

Deliveries are made across a broad customer field in more<br />

than 40 countries. International corporations and renowned<br />

machinery and plant manufacturers rely on <strong>ZIMM</strong>‘s innovative<br />

products and solutions.<br />

<strong>ZIMM</strong> offers customer-specific advice to achieve tailored<br />

solutions that fulfill different requirements.<br />

Whether you are looking for an individual drive or a complete<br />

system, <strong>ZIMM</strong> has the right solution.<br />

FACTBOX:<br />

<strong>ZIMM</strong> Austria<br />

CEO:<br />

Gunther Zimmermann<br />

Established: 1977<br />

Employees: 110<br />

Registered offices: Austria, <strong>US</strong>A (since 2016)<br />

Products: Manufacture of screw jack systems and<br />

transmission parts<br />

ISO certificate: ISO9001:2008<br />

<strong>ZIMM</strong> <strong>US</strong>A<br />

©<strong>ZIMM</strong> Maschinenelemente GmbH + Co KG: All rights reserved. No extract of these documents maybe duplicated or transmitted for whatever purposes without<br />

the explicit and written authorization of <strong>ZIMM</strong> Maschinenelemente GmbH + Co KG. Printing or other errors excepted. Technical details subject to changes. Version XII 1.1, 03/2017<br />

<strong>US</strong>A:<br />

<strong>ZIMM</strong> <strong>US</strong>A Inc.<br />

1001 Mittel Drive<br />

Wood Dale, IL 60191<br />

Phone: 224-765-0663<br />

Fax: 630-354-6840<br />

E-mail: info@zimmscrewjacks.us<br />

Internet: www.zimmscrewjacks.us<br />

A<strong>US</strong>TRIA – Headquarters:<br />

<strong>ZIMM</strong> Maschinenelemente GmbH + Co KG<br />

Millennium Park 3<br />

6890 Lustenau<br />

Phone: 00435577/806-0<br />

Fax: 00435577/806-8<br />

E-mail: info@zimm.at<br />

Internet: www.zimm.eu