HOLCIM AR 2016 FA_LR 5-26-17

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

46 | <strong>2016</strong> Annual Report<br />

Holcim Philippines | 47<br />

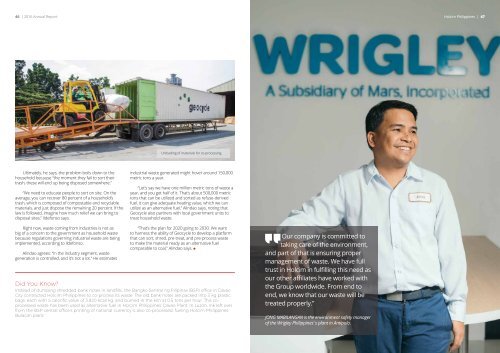

Unloading of materials for co-processing<br />

Ultimately, he says, the problem boils down to the<br />

household because “the moment they fail to sort their<br />

trash, these will end up being disposed somewhere.”<br />

“We need to educate people to sort on site. On the<br />

average, you can recover 80 percent of a household’s<br />

trash, which is composed of compostable and recyclable<br />

materials, and just dispose the remaining 20 percent. If the<br />

law is followed, imagine how much relief we can bring to<br />

disposal sites,” Ildefonso says.<br />

industrial waste generated might hover around 150,000<br />

metric tons a year.<br />

“Let’s say we have one million metric tons of waste a<br />

year, and you get half of it. That’s about 500,000 metric<br />

tons that can be utilized and sorted as refuse-derived<br />

fuel. It can give adequate heating value, which we can<br />

utilize as an alternative fuel,” Alindao says, noting that<br />

Geocycle also partners with local government units to<br />

treat household waste.<br />

Right now, waste coming from industries is not as<br />

big of a concern to the government as household waste<br />

because regulations governing industrial waste are being<br />

implemented, according to Ildefonso.<br />

Alindao agrees: “In the industry segment, waste<br />

generation is controlled, and it’s not a lot.” He estimates<br />

“That’s the plan for 2020 going to 2030. We want<br />

to harness the ability of Geocycle to develop a platform<br />

that can sort, shred, pre-treat, and pre-process waste<br />

to make the material ready as an alternative fuel<br />

comparable to coal,” Alindao says.<br />

Did You Know?<br />

Instead of dumping shredded bank notes in landfills, the Bangko Sentral ng Pilipinas (BSP) office in Davao<br />

City contracted Holcim Philippines to co-process its waste. The old bank notes are packed into 3 kg plastic<br />

bags, each with a calorific value of 3,820 kcal/ kg, and burned in the kiln at 0.5 tons per hour. This coprocessed<br />

waste has been used as alternative fuel in Holcim Philippines’ Davao Plant. In Luzon, ink left over<br />

from the BSP central office’s printing of national currency is also co-processed, fueling Holcim Philippines’<br />

Bulacan plant.<br />

Our company is committed to<br />

taking care of the environment,<br />

and part of that is ensuring proper<br />

management of waste. We have full<br />

trust in Holcim in fulfilling this need as<br />

our other affiliates have worked with<br />

the Group worldwide. From end to<br />

end, we know that our waste will be<br />

treated properly.”<br />

JONG MABILANGAN is the environment safety manager<br />

of the Wrigley Philippines’ s plant in Antipolo.