issue_2_2017_rev2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

36<br />

processing & packaging<br />

3. Tender Aligner (optional<br />

chicken tenders) to reduce<br />

manual labour.<br />

4. Wet Dipper to guarantee<br />

coverage of irregular shapes<br />

even with thick batters and<br />

high belt speeds.<br />

5. EasyFry XL for par fry fitted<br />

with Oberlin oil filter to extend<br />

oil life and maintain taste,<br />

colour and quality.<br />

6. CookStar spiral oven that<br />

seals in moisture and<br />

provides a crispy coating.<br />

more consistent appearance.<br />

Cleaning the oil and cooking<br />

Luuc Lankveld adds, “Another<br />

strong point of our line solution is<br />

related to oil life. When par-frying<br />

flour coated products, tiny<br />

particles come loose and burn,<br />

which not only degrades the oil<br />

and shortens its life, it also<br />

influences taste. To<br />

stop this<br />

moisture. In the final zone, hot air<br />

with a higher temperature and<br />

lower dew point create the crispy<br />

coating so important for<br />

homestyle. The booster/turbo<br />

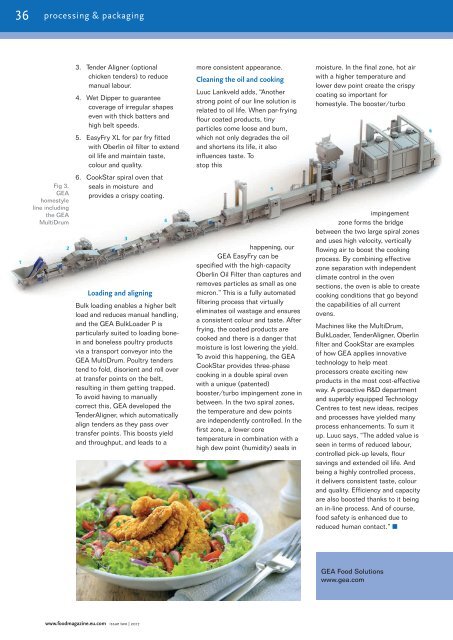

Fig 3.<br />

GEA<br />

homestyle<br />

line including<br />

the GEA<br />

MultiDrum<br />

Loading and aligning<br />

Bulk loading enables a higher belt<br />

load and reduces manual handling,<br />

and the GEA BulkLoader P is<br />

particularly suited to loading bonein<br />

and boneless poultry products<br />

via a transport conveyor into the<br />

GEA MultiDrum. Poultry tenders<br />

tend to fold, disorient and roll over<br />

at transfer points on the belt,<br />

resulting in them getting trapped.<br />

To avoid having to manually<br />

correct this, GEA developed the<br />

TenderAligner, which automatically<br />

align tenders as they pass over<br />

transfer points. This boosts yield<br />

and throughput, and leads to a<br />

happening, our<br />

GEA EasyFry can be<br />

specified with the high-capacity<br />

Oberlin Oil Filter than captures and<br />

removes particles as small as one<br />

micron.” This is a fully automated<br />

filtering process that virtually<br />

eliminates oil wastage and ensures<br />

a consistent colour and taste. After<br />

frying, the coated products are<br />

cooked and there is a danger that<br />

moisture is lost lowering the yield.<br />

To avoid this happening, the GEA<br />

CookStar provides three-phase<br />

cooking in a double spiral oven<br />

with a unique (patented)<br />

booster/turbo impingement zone in<br />

between. In the two spiral zones,<br />

the temperature and dew points<br />

are independently controlled. In the<br />

first zone, a lower core<br />

temperature in combination with a<br />

high dew point (humidity) seals in<br />

impingement<br />

zone forms the bridge<br />

between the two large spiral zones<br />

and uses high velocity, vertically<br />

flowing air to boost the cooking<br />

process. By combining effective<br />

zone separation with independent<br />

climate control in the oven<br />

sections, the oven is able to create<br />

cooking conditions that go beyond<br />

the capabilities of all current<br />

ovens.<br />

Machines like the MultiDrum,<br />

BulkLoader, TenderAligner, Oberlin<br />

filter and CookStar are examples<br />

of how GEA applies innovative<br />

technology to help meat<br />

processors create exciting new<br />

products in the most cost-effective<br />

way. A proactive R&D department<br />

and superbly equipped Technology<br />

Centres to test new ideas, recipes<br />

and processes have yielded many<br />

process enhancements. To sum it<br />

up. Luuc says, “The added value is<br />

seen in terms of reduced labour,<br />

controlled pick-up levels, flour<br />

savings and extended oil life. And<br />

being a highly controlled process,<br />

it delivers consistent taste, colour<br />

and quality. Efficiency and capacity<br />

are also boosted thanks to it being<br />

an in-line process. And of course,<br />

food safety is enhanced due to<br />

reduced human contact.” n<br />

GEA Food Solutions<br />

www.gea.com<br />

www.foodmagazine.eu.com <strong>issue</strong> two | <strong>2017</strong>