Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6<br />

YORGLAS Magazine | July <strong>2017</strong><br />

Message from<br />

General Manager<br />

YAVUZ MERT General Manager, Yorglas®<br />

Dear Partners,<br />

It is very pleasant for us to make contact to<br />

you after a short time. In this issue, I wanted<br />

to talk about the structure of the Industry 4.0<br />

which we have followed closely in <strong>2017</strong> as Cam<br />

Merkezi, we have reviewed each process and<br />

now the most up-to-date topic of our day.<br />

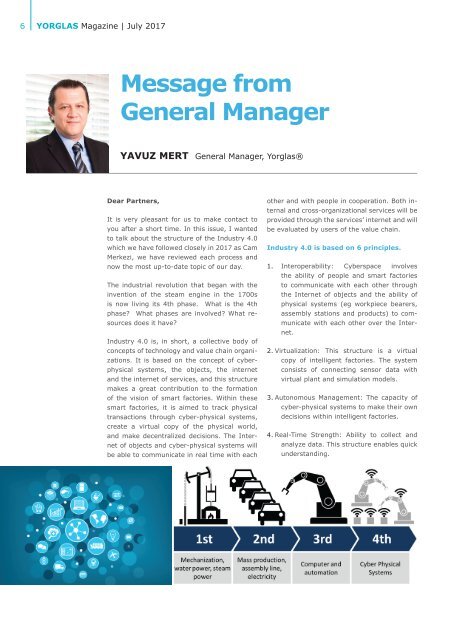

The industrial revolution that began with the<br />

invention of the steam engine in the 1700s<br />

is now living its 4th phase. What is the 4th<br />

phase? What phases are involved? What resources<br />

does it have?<br />

Industry 4.0 is, in short, a collective body of<br />

concepts of technology and value chain organizations.<br />

It is based on the concept of cyberphysical<br />

systems, the objects, the internet<br />

and the internet of services, and this structure<br />

makes a great contribution to the formation<br />

of the vision of smart factories. Within these<br />

smart factories, it is aimed to track physical<br />

transactions through cyber-physical systems,<br />

create a virtual copy of the physical world,<br />

and make decentralized decisions. The Internet<br />

of objects and cyber-physical systems will<br />

be able to communicate in real time with each<br />

other and with people in cooperation. Both internal<br />

and cross-organizational services will be<br />

provided through the services’ internet and will<br />

be evaluated by users of the value chain.<br />

Industry 4.0 is based on 6 principles.<br />

1. Interoperability: Cyberspace involves<br />

the ability of people and smart factories<br />

to communicate with each other through<br />

the Internet of objects and the ability of<br />

physical systems (eg workpiece bearers,<br />

assembly stations and products) to communicate<br />

with each other over the Internet.<br />

2. Virtualization: This structure is a virtual<br />

copy of intelligent factories. The system<br />

consists of connecting sensor data with<br />

virtual plant and simulation models.<br />

3. Autonomous Management: The capacity of<br />

cyber-physical systems to make their own<br />

decisions within intelligent factories.<br />

4. Real-Time Strength: Ability to collect and<br />

analyze data. This structure enables quick<br />

understanding.