Space Transportation - mmmt_transportation.pdf - Moon Society

Space Transportation - mmmt_transportation.pdf - Moon Society

Space Transportation - mmmt_transportation.pdf - Moon Society

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

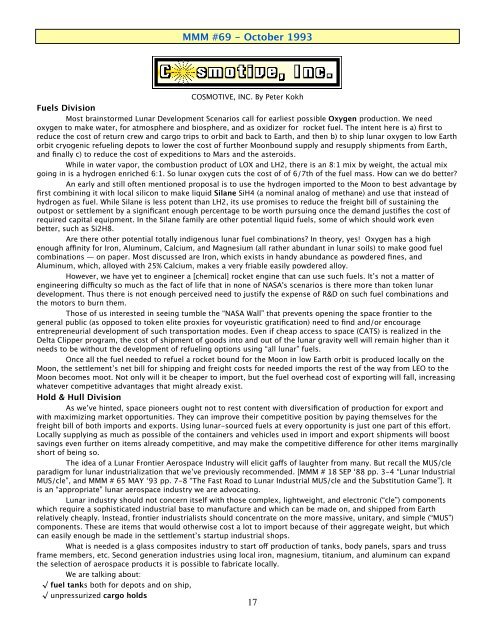

MMM #69 - October 1993<br />

COSMOTIVE, INC. By Peter Kokh<br />

Fuels Division<br />

Most brainstormed Lunar Development Scenarios call for earliest possible Oxygen production. We need<br />

oxygen to make water, for atmosphere and biosphere, and as oxidizer for rocket fuel. The intent here is a) first to<br />

reduce the cost of return crew and cargo trips to orbit and back to Earth, and then b) to ship lunar oxygen to low Earth<br />

orbit cryogenic refueling depots to lower the cost of further <strong>Moon</strong>bound supply and resupply shipments from Earth,<br />

and finally c) to reduce the cost of expeditions to Mars and the asteroids.<br />

While in water vapor, the combustion product of LOX and LH2, there is an 8:1 mix by weight, the actual mix<br />

going in is a hydrogen enriched 6:1. So lunar oxygen cuts the cost of of 6/7th of the fuel mass. How can we do better?<br />

An early and still often mentioned proposal is to use the hydrogen imported to the <strong>Moon</strong> to best advantage by<br />

first combining it with local silicon to make liquid Silane SiH4 (a nominal analog of methane) and use that instead of<br />

hydrogen as fuel. While Silane is less potent than LH2, its use promises to reduce the freight bill of sustaining the<br />

outpost or settlement by a significant enough percentage to be worth pursuing once the demand justifies the cost of<br />

required capital equipment. In the Silane family are other potential liquid fuels, some of which should work even<br />

better, such as Si2H8.<br />

Are there other potential totally indigenous lunar fuel combinations? In theory, yes! Oxygen has a high<br />

enough affinity for Iron, Aluminum, Calcium, and Magnesium (all rather abundant in lunar soils) to make good fuel<br />

combinations — on paper. Most discussed are Iron, which exists in handy abundance as powdered fines, and<br />

Aluminum, which, alloyed with 25% Calcium, makes a very friable easily powdered alloy.<br />

However, we have yet to engineer a [chemical] rocket engine that can use such fuels. It’s not a matter of<br />

engineering difficulty so much as the fact of life that in none of NASA's scenarios is there more than token lunar<br />

development. Thus there is not enough perceived need to justify the expense of R&D on such fuel combinations and<br />

the motors to burn them.<br />

Those of us interested in seeing tumble the “NASA Wall” that prevents opening the space frontier to the<br />

general public (as opposed to token elite proxies for voyeuristic gratification) need to find and/or encourage<br />

entrepreneurial development of such <strong>transportation</strong> modes. Even if cheap access to space (CATS) is realized in the<br />

Delta Clipper program, the cost of shipment of goods into and out of the lunar gravity well will remain higher than it<br />

needs to be without the development of refueling options using “all lunar” fuels.<br />

Once all the fuel needed to refuel a rocket bound for the <strong>Moon</strong> in low Earth orbit is produced locally on the<br />

<strong>Moon</strong>, the settlement’s net bill for shipping and freight costs for needed imports the rest of the way from LEO to the<br />

<strong>Moon</strong> becomes moot. Not only will it be cheaper to import, but the fuel overhead cost of exporting will fall, increasing<br />

whatever competitive advantages that might already exist.<br />

Hold & Hull Division<br />

As we’ve hinted, space pioneers ought not to rest content with diversification of production for export and<br />

with maximizing market opportunities. They can improve their competitive position by paying themselves for the<br />

freight bill of both imports and exports. Using lunar-sourced fuels at every opportunity is just one part of this effort.<br />

Locally supplying as much as possible of the containers and vehicles used in import and export shipments will boost<br />

savings even further on items already competitive, and may make the competitive difference for other items marginally<br />

short of being so.<br />

The idea of a Lunar Frontier Aerospace Industry will elicit gaffs of laughter from many. But recall the MUS/cle<br />

paradigm for lunar industrialization that we’ve previously recommended. [MMM # 18 SEP ‘88 pp. 3-4 “Lunar Industrial<br />

MUS/cle”, and MMM # 65 MAY ‘93 pp. 7-8 “The Fast Road to Lunar Industrial MUS/cle and the Substitution Game”]. It<br />

is an “appropriate” lunar aerospace industry we are advocating.<br />

Lunar industry should not concern itself with those complex, lightweight, and electronic (“cle”) components<br />

which require a sophisticated industrial base to manufacture and which can be made on, and shipped from Earth<br />

relatively cheaply. Instead, frontier industrialists should concentrate on the more massive, unitary, and simple (“MUS”)<br />

components. These are items that would otherwise cost a lot to import because of their aggregate weight, but which<br />

can easily enough be made in the settlement’s startup industrial shops.<br />

What is needed is a glass composites industry to start off production of tanks, body panels, spars and truss<br />

frame members, etc. Second generation industries using local iron, magnesium, titanium, and aluminum can expand<br />

the selection of aerospace products it is possible to fabricate locally.<br />

We are talking about:<br />

√ fuel tanks both for depots and on ship,<br />

√ unpressurized cargo holds<br />

17