ZERODUR® - Mark Optics Inc.

ZERODUR® - Mark Optics Inc.

ZERODUR® - Mark Optics Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

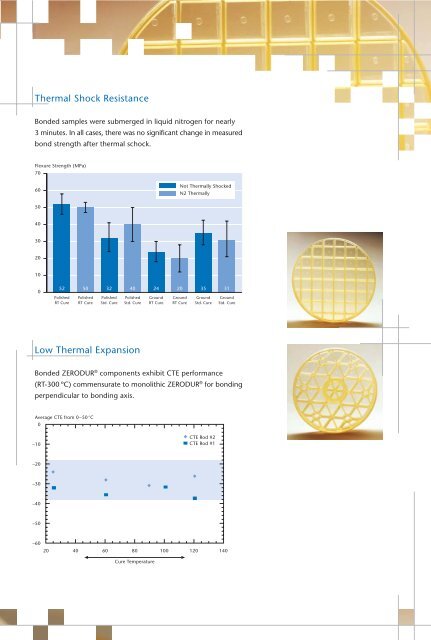

Thermal Shock Resistance<br />

Bonded samples were submerged in liquid nitrogen for nearly<br />

3 minutes. In all cases, there was no significant change in measured<br />

bond strength after thermal schock.<br />

Flexure Strength (MPa)<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

52 50 32 40 24<br />

Polished<br />

RT Cure<br />

Polished<br />

RT Cure<br />

Polished<br />

Std. Cure<br />

Polished<br />

Std. Cure<br />

Low Thermal Expansion<br />

Ground<br />

RT Cure<br />

Not Thermally Shocked<br />

N2 Thermally<br />

20 35 31<br />

Ground<br />

RT Cure<br />

Ground<br />

Std. Cure<br />

Ground<br />

Std. Cure<br />

Bonded ZERODUR ® components exhibit CTE performance<br />

(RT-300 ºC) commensurate to monolithic ZERODUR ® for bonding<br />

perpendicular to bonding axis.<br />

Average CTE from 0–50°C<br />

0<br />

–10<br />

–20<br />

–30<br />

–40<br />

–50<br />

–60<br />

Cure Temperature<br />

CTE Rod #2<br />

CTE Rod #1<br />

20 40 60 80 100 120 140