Metro Rail News October 2017

October Edition 2017. Owned and published by Symbroj Media Pvt. Ltd., New Delhi, India

October Edition 2017. Owned and published by Symbroj Media Pvt. Ltd., New Delhi, India

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Protection against Human Error – A general principal<br />

within the safety community is, the less human<br />

interaction, the safer it is. A conventional signalling<br />

system depends on the operator to follow the rules of<br />

the railroad. If an operator violates a safety critical<br />

procedure (speed limit around a curve for example),<br />

safety is compromised. Whereas a CBTC system is<br />

automated and the human element is removed or<br />

reduced significantly.<br />

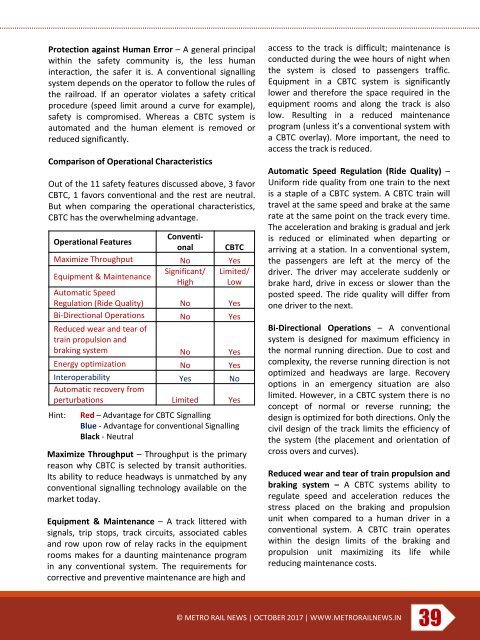

Comparison of Operational Characteristics<br />

Out of the 11 safety features discussed above, 3 favor<br />

CBTC, 1 favors conventional and the rest are neutral.<br />

But when comparing the operational characteristics,<br />

CBTC has the overwhelming advantage.<br />

Operational Features<br />

Conventional<br />

CBTC<br />

Maximize Throughput No Yes<br />

Equipment & Maintenance<br />

Significant/ Limited/<br />

High Low<br />

Automatic Speed<br />

Regulation (Ride Quality) No Yes<br />

Bi-Directional Operations No Yes<br />

Reduced wear and tear of<br />

train propulsion and<br />

braking system No Yes<br />

Energy optimization No Yes<br />

Interoperability Yes No<br />

Automatic recovery from<br />

perturbations Limited Yes<br />

Hint:<br />

Red – Advantage for CBTC Signalling<br />

Blue - Advantage for conventional Signalling<br />

Black - Neutral<br />

Maximize Throughput – Throughput is the primary<br />

reason why CBTC is selected by transit authorities.<br />

Its ability to reduce headways is unmatched by any<br />

conventional signalling technology available on the<br />

market today.<br />

Equipment & Maintenance – A track littered with<br />

signals, trip stops, track circuits, associated cables<br />

and row upon row of relay racks in the equipment<br />

rooms makes for a daunting maintenance program<br />

in any conventional system. The requirements for<br />

corrective and preventive maintenance are high and<br />

access to the track is difficult; maintenance is<br />

conducted during the wee hours of night when<br />

the system is closed to passengers traffic.<br />

Equipment in a CBTC system is significantly<br />

lower and therefore the space required in the<br />

equipment rooms and along the track is also<br />

low. Resulting in a reduced maintenance<br />

program (unless it’s a conventional system with<br />

a CBTC overlay). More important, the need to<br />

access the track is reduced.<br />

Automatic Speed Regulation (Ride Quality) –<br />

Uniform ride quality from one train to the next<br />

is a staple of a CBTC system. A CBTC train will<br />

travel at the same speed and brake at the same<br />

rate at the same point on the track every time.<br />

The acceleration and braking is gradual and jerk<br />

is reduced or eliminated when departing or<br />

arriving at a station. In a conventional system,<br />

the passengers are left at the mercy of the<br />

driver. The driver may accelerate suddenly or<br />

brake hard, drive in excess or slower than the<br />

posted speed. The ride quality will differ from<br />

one driver to the next.<br />

Bi-Directional Operations – A conventional<br />

system is designed for maximum efficiency in<br />

the normal running direction. Due to cost and<br />

complexity, the reverse running direction is not<br />

optimized and headways are large. Recovery<br />

options in an emergency situation are also<br />

limited. However, in a CBTC system there is no<br />

concept of normal or reverse running; the<br />

design is optimized for both directions. Only the<br />

civil design of the track limits the efficiency of<br />

the system (the placement and orientation of<br />

cross overs and curves).<br />

Reduced wear and tear of train propulsion and<br />

braking system – A CBTC systems ability to<br />

regulate speed and acceleration reduces the<br />

stress placed on the braking and propulsion<br />

unit when compared to a human driver in a<br />

conventional system. A CBTC train operates<br />

within the design limits of the braking and<br />

propulsion unit maximizing its life while<br />

reducing maintenance costs.<br />

© METRO RAIL NEWS | OCTOBER <strong>2017</strong> | WWW.METRORAILNEWS.IN<br />

39