A rough set approach for evaluating vague customer requirement of industrial product-service system_Wenyan Songa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6686 W. Song et al.<br />

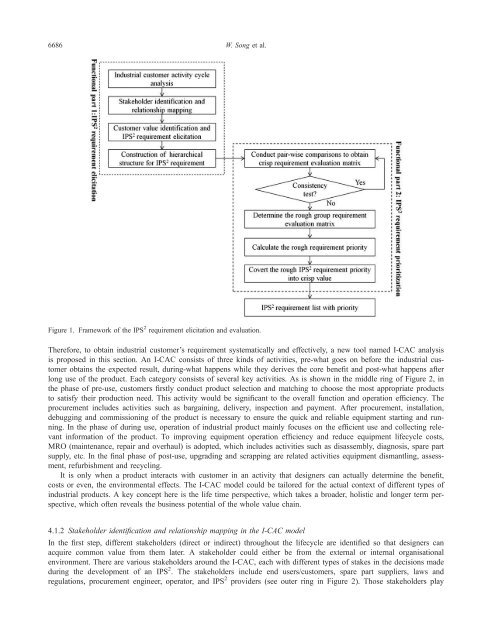

Figure 1. Framework <strong>of</strong> the IPS 2 <strong>requirement</strong> elicitation and evaluation.<br />

There<strong>for</strong>e, to obtain <strong>industrial</strong> <strong>customer</strong>’s <strong>requirement</strong> <strong>system</strong>atically and effectively, a new tool named I-CAC analysis<br />

is proposed in this section. An I-CAC consists <strong>of</strong> three kinds <strong>of</strong> activities, pre-what goes on be<strong>for</strong>e the <strong>industrial</strong> <strong>customer</strong><br />

obtains the expected result, during-what happens while they derives the core benefit and post-what happens after<br />

long use <strong>of</strong> the <strong>product</strong>. Each category consists <strong>of</strong> several key activities. As is shown in the middle ring <strong>of</strong> Figure 2, in<br />

the phase <strong>of</strong> pre-use, <strong>customer</strong>s firstly conduct <strong>product</strong> selection and matching to choose the most appropriate <strong>product</strong>s<br />

to satisfy their <strong>product</strong>ion need. This activity would be significant to the overall function and operation efficiency. The<br />

procurement includes activities such as bargaining, delivery, inspection and payment. After procurement, installation,<br />

debugging and commissioning <strong>of</strong> the <strong>product</strong> is necessary to ensure the quick and reliable equipment starting and running.<br />

In the phase <strong>of</strong> during use, operation <strong>of</strong> <strong>industrial</strong> <strong>product</strong> mainly focuses on the efficient use and collecting relevant<br />

in<strong>for</strong>mation <strong>of</strong> the <strong>product</strong>. To improving equipment operation efficiency and reduce equipment lifecycle costs,<br />

MRO (maintenance, repair and overhaul) is adopted, which includes activities such as disassembly, diagnosis, spare part<br />

supply, etc. In the final phase <strong>of</strong> post-use, upgrading and scrapping are related activities equipment dismantling, assessment,<br />

refurbishment and recycling.<br />

It is only when a <strong>product</strong> interacts with <strong>customer</strong> in an activity that designers can actually determine the benefit,<br />

costs or even, the environmental effects. The I-CAC model could be tailored <strong>for</strong> the actual context <strong>of</strong> different types <strong>of</strong><br />

<strong>industrial</strong> <strong>product</strong>s. A key concept here is the life time perspective, which takes a broader, holistic and longer term perspective,<br />

which <strong>of</strong>ten reveals the business potential <strong>of</strong> the whole value chain.<br />

4.1.2 Stakeholder identification and relationship mapping in the I-CAC model<br />

In the first step, different stakeholders (direct or indirect) th<strong>rough</strong>out the lifecycle are identified so that designers can<br />

acquire common value from them later. A stakeholder could either be from the external or internal organisational<br />

environment. There are various stakeholders around the I-CAC, each with different types <strong>of</strong> stakes in the decisions made<br />

during the development <strong>of</strong> an IPS 2 . The stakeholders include end users/<strong>customer</strong>s, spare part suppliers, laws and<br />

regulations, procurement engineer, operator, and IPS 2 providers (see outer ring in Figure 2). Those stakeholders play