+++guide-for-doggers-ODLICNO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

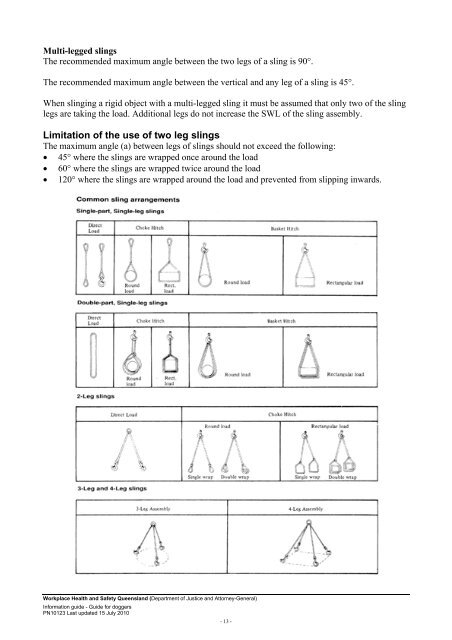

Multi-legged slings<br />

The recommended maximum angle between the two legs of a sling is 90°.<br />

The recommended maximum angle between the vertical and any leg of a sling is 45°.<br />

When slinging a rigid object with a multi-legged sling it must be assumed that only two of the sling<br />

legs are taking the load. Additional legs do not increase the SWL of the sling assembly.<br />

Limitation of the use of two leg slings<br />

The maximum angle (a) between legs of slings should not exceed the following:<br />

• 45° where the slings are wrapped once around the load<br />

• 60° where the slings are wrapped twice around the load<br />

• 120° where the slings are wrapped around the load and prevented from slipping inwards.<br />

Workplace Health and Safety Queensland (Department of Justice and Attorney-General)<br />

In<strong>for</strong>mation guide - Guide <strong>for</strong> <strong>doggers</strong><br />

PN10123 Last updated 15 July 2010<br />

- 13 -