Transport Britain Issue 4

Transport Britain Publication Issue 4

Transport Britain Publication Issue 4

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ISSN 2015-6861<br />

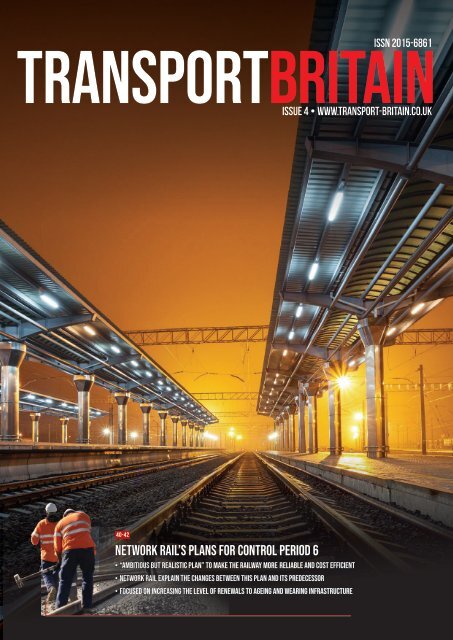

TRANSPORTBRITAIN<br />

ISSUE 4 • WWW.TRANSPORT-BRITAIN.CO.UK<br />

40-42<br />

NETWORK RAIL’S PLANS FOR CONTROL PERIOD 6<br />

• “AMBITIOUS BUT REALISTIC PLAN” TO MAKE THE RAILWAY MORE RELIABLE AND COST EFFICIENT<br />

• NETWORK RAIL EXPLAIN THE CHANGES BETWEEN THIS PLAN AND ITS PREDECESSOR<br />

• FOCUSED ON INCREASING THE LEVEL OF RENEWALS TO AGEING AND WEARING INFRASTRUCTURE

Redi-Rock modular retaining wall system<br />

.....with the look of natural stone!<br />

Rail Products<br />

Build Faster<br />

Build Leaner<br />

Build Greener<br />

Build Quality<br />

Build Smarter<br />

Build to Last<br />

1066kg<br />

Download BIM and free Redi-Rock<br />

design software at www.cpm-group.com<br />

Dry laid one tonne large interlocking concrete blocks<br />

Extremely fast and easy to install<br />

Can be built in any weather<br />

Standard blocks.... no waste<br />

Produced from 40% recycled materials<br />

100 year design life<br />

Gravity and reinforced earth walls available<br />

Designed in accordance with BS EN 1997-1:2004<br />

Installation support or full installation service available<br />

Full design service supported by professional indemnity insurance<br />

Now available in three natural finishes...<br />

Ledgestone Cobblestone Limestone<br />

To find out more see our<br />

website or call our sales team.<br />

T: 01179 814500<br />

F: 01179 814511<br />

E: sales@cpm-group.com<br />

www.redi-rock.com<br />

www.cpm-group.com<br />

Concrete for Life

16 22 30 36<br />

FROM THE EDITOR<br />

Hello and welcome to our<br />

latest issue of <strong>Transport</strong><br />

<strong>Britain</strong>. Since our last<br />

publication, we have seen<br />

significant progress in<br />

work on the Elizabeth line.<br />

We have a round-up of all<br />

Crossrail developments, as<br />

well as those on HS2.<br />

Previously, we spoke to<br />

the Office of Rail and Road<br />

to get their take on how<br />

Network Rail’s spending<br />

for Control Period 6 will<br />

be monitored. Here,<br />

we get the opinions of<br />

Network Rail regarding the<br />

Strategic Business Plan<br />

which sets out spending<br />

ambitions between 2019<br />

– 2024, why they feel it is<br />

their best ever plan, and<br />

what challenges await<br />

in order to ensure it is<br />

implemented.<br />

The last few months have<br />

also seen the launch of<br />

the UK Rail Research<br />

and Innovation Network<br />

(UKRRIN) – the result of<br />

which will drive changes<br />

in digital technologies in<br />

the rail industry. Professor<br />

Clive Roberts at the<br />

University of Birmingham<br />

has spoken about how the<br />

partnership will change<br />

the rail sector.<br />

Elsewhere, we have<br />

spoken to companies<br />

including Hako and<br />

APP, whose products<br />

have made – or have<br />

the potential to make –<br />

significant changes to the<br />

streets of the UK.<br />

Meanwhile, all major<br />

developments in the road<br />

and rail industries, as well<br />

as progress on Carillion’s<br />

former contacts, are<br />

covered in this issue.<br />

John Train - Editor<br />

MEDIA ENQUIRIES<br />

Sales & Advertising 01625 682017 • enquiries@transport-britain.co.uk<br />

Editor john.train@businessbritainmedia.co.uk Design JMO Creative Design<br />

<strong>Transport</strong> <strong>Britain</strong> Media<br />

A The Ropewalks, Newton Street,<br />

Macclesfield, Cheshire SK11 6QJ<br />

T 01625 682017<br />

E enquiries@transport-britain.co.uk<br />

w www.transport-britain.co.uk<br />

<strong>Transport</strong> <strong>Britain</strong> is a unique business to business<br />

marketing platform aimed at bringing together the<br />

best of British Business and providing the opportunity<br />

to showcase products and services relevant to the<br />

development and success of British companies in the<br />

domestic and international market place.<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

3

LATEST INDUSTRY NEWS<br />

//. GOVERNMENT INVITES INVESTORS TO PUT<br />

FORWARD PROPOSALS FOR HEATHROW RAIL LINK<br />

THE Department for <strong>Transport</strong><br />

has called on private<br />

companies to give their ideas<br />

on the best way to deliver a<br />

southern rail link to Heathrow<br />

Airport.<br />

Chris Grayling has invited<br />

those organisations to come<br />

forward who want to invest in<br />

rail infrastructure so that they<br />

can share their ideas for this<br />

new rail link, along with other<br />

projects that will upgrade and<br />

expand the railway network in<br />

<strong>Britain</strong>.<br />

This invitation for ideas<br />

regarding a new southern rail<br />

link at Heathrow Airport is<br />

significant because it is one<br />

of the first projects that falls<br />

under these new government<br />

plans which will see third<br />

parties invest in the rail<br />

network and see their ideas<br />

come to fruition.<br />

The government hopes this<br />

will increase the £47 billion it<br />

has committed to spending on<br />

rail in the next five years, and<br />

interest in constructing the<br />

southern link to Heathrow is<br />

high, with numerous consortia<br />

already registering their<br />

interest.<br />

Mr Grayling reiterated that<br />

investment would have to make<br />

commercial sense and build<br />

on the infrastructure already<br />

in place, and ultimately put the<br />

needs of passengers first.<br />

He explained: “We are<br />

investing in the most significant<br />

modernisation of the UK rail<br />

network since Victorian times,<br />

and I want the knowledge and<br />

expertise of investors and<br />

local partners to contribute to<br />

delivering new connections,<br />

more services and better<br />

journeys for passengers.<br />

“This has already proved<br />

effective on a number of<br />

roads schemes in the UK. By<br />

encouraging innovative ideas<br />

and new investment on our<br />

railways, we can relieve the<br />

burden on taxpayers and fare<br />

payers with projects that match<br />

our transport needs.<br />

“This can also support our<br />

economic and housing<br />

aspirations to ensure everyone<br />

benefits from an enhanced rail<br />

network.<br />

“Heathrow is a perfect example<br />

of where this can make a real<br />

difference. Such schemes will<br />

help ensure the benefits of<br />

our major international hub<br />

are even more accessible to<br />

those across the west and<br />

the south of the UK, providing<br />

vital links for travellers and<br />

exporters and attracting inward<br />

investment.”<br />

It is hoped this call for investors<br />

will lead to a new method of<br />

funding transport projects,<br />

creating a whole new tier of<br />

investment from the private<br />

sector.<br />

4 TRANSPORT BRITAIN • APRIL 2018

LATEST INDUSTRY NEWS<br />

//. TRANSPORT FOR LONDON PUBLISHES<br />

ITS DRAFT BUDGET FOR 2018/19<br />

TRANSPORT for London<br />

(TfL) has published its draft<br />

budget for 2018/19, outlining<br />

improvements to rail services<br />

that can be expected.<br />

It forms the start of TfL’s<br />

five-year Business Plan which<br />

was published last year and<br />

is in line with the <strong>Transport</strong><br />

Strategy set out by the Mayor<br />

of London. This will see<br />

investment hit a record high on<br />

public transport.<br />

The draft budget reveals the<br />

improvements that will be<br />

delivered for the capital’s transport<br />

network over the next year, as well<br />

as outlining how modernisation<br />

will be delivered against a<br />

backdrop of huge reductions in<br />

government funding.<br />

TfL say that costs of running<br />

the transport network fell by<br />

£153 million in the last financial<br />

year and believe costs will<br />

continue to fall.<br />

At this rate, despite lower<br />

income than forecast, the<br />

draft budget gives details on<br />

expectations that this trend<br />

will continue, resulting in an<br />

operating surplus by 2021/22.<br />

It is an exciting time for<br />

London’s transport network<br />

and the draft budget<br />

says in 2018/19, a host of<br />

improvements will be delivered.<br />

This includes the delivery of the<br />

Elizabeth line from December<br />

2018 onwards and by the<br />

December afterwards, stepfree<br />

access will be available at<br />

every station serviced by the<br />

new rail line.<br />

The London Underground will<br />

continue to be modernised,<br />

with signalling and step-free<br />

access all incorporated, while<br />

capacity on the rail network will<br />

continue to be increased.<br />

Elsewhere, land belonging to<br />

TfL will be used to construct<br />

commercial space and housing,<br />

50% of which will be affordable<br />

– part of Sadiq Khan’s drive to<br />

increase affordable housing in<br />

the city.<br />

Val Shawcross, Deputy Mayor<br />

for <strong>Transport</strong>, said: “The next<br />

year will be a truly exciting time<br />

for London, with the opening<br />

of the Elizabeth line, and major<br />

projects like the transformation<br />

of Oxford Street.<br />

“At the same time, the budget<br />

shows how we’re also looking<br />

to the future with further<br />

tube modernisation and an<br />

unprecedented commitment<br />

to walking and cycling<br />

infrastructure.”<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

5

. AMBITIOUS TRANSPORT STRATEGY<br />

FOR LONDON OUTLINED BY THE MAYOR<br />

Ambitious plans to improve<br />

London’s transport in the next<br />

25 years have been outlined<br />

in the Mayor of London’s<br />

<strong>Transport</strong> Strategy.<br />

Presented to the London<br />

Assembly for consideration, the<br />

<strong>Transport</strong> Strategy will be the<br />

backbone of transport planning<br />

in the capital.<br />

The Strategy incorporates<br />

record investment plans which<br />

will result in new and improved<br />

rail in London, while tube and<br />

bus services will also benefit.<br />

It follows Sadiq Khan’s draft<br />

strategy last year which has<br />

seen in excess of 6,500 key<br />

stakeholders and members of<br />

the public respond to it.<br />

The <strong>Transport</strong> Strategy will<br />

make the capital even more<br />

accessible for people and<br />

businesses through the use of<br />

new Tube trains and signalling<br />

which will increase their<br />

frequency.<br />

Elsewhere, the Elizabeth line will<br />

open in December, alleviating<br />

the strain on other parts of the<br />

network whilst also providing a<br />

brand new service that will also<br />

boost the economy.<br />

Extensions to the Tube,<br />

London Overground and<br />

DLR are also covered in the<br />

<strong>Transport</strong> Strategy, which also<br />

highlights the importance of<br />

Crossrail 2 – something that<br />

will be reviewed to outline how<br />

it will provide value for money<br />

to the taxpayer – on economy,<br />

jobs and the ability to unlock<br />

housing sites.<br />

The feedback from the<br />

consultation means that the<br />

Mayor’s <strong>Transport</strong> Strategy<br />

includes potential for a west<br />

London Orbital rail line.<br />

Val Shawcross is the Deputy<br />

Mayor for <strong>Transport</strong>. She said<br />

the Strategy will provide ‘world<br />

class’ services.<br />

She said: “Our ambitious<br />

strategy for the next 25 years<br />

shows how we can provide<br />

affordable, accessible and<br />

world class transport for every<br />

Londoner, while ensuring our<br />

transport network acts as a<br />

huge catalyst for new jobs and<br />

homes across the capital.<br />

“We have looked closely at<br />

the input from thousands of<br />

people who have responded<br />

to the consultation and I’m<br />

pleased that our bold focus on<br />

encouraging walking, cycling<br />

and public transport, alongside<br />

reducing emissions, remains at<br />

the heart of our Strategy.”<br />

6 TRANSPORT BRITAIN • APRIL 2018

LATEST INDUSTRY NEWS<br />

//. NETWORK RAIL UNVEILS STRATEGIC<br />

BUSINESS PLAN FOR CONTROL PERIOD 6<br />

Network Rail has unveiled its<br />

Strategic Business Plan which<br />

will improve the railways in<br />

Control Period 6 (CP6) from<br />

2019 to 2024.<br />

Record expenditure of up to<br />

£47 billion is expected over<br />

the five-year period, which will<br />

deliver railway upgrades to<br />

benefit the millions of people<br />

who use it.<br />

As well as this, the investment<br />

will drive economic growth,<br />

create jobs and unlock housing<br />

along railway routes which<br />

will be reliable, have greater<br />

cost efficiency, and even more<br />

capacity.<br />

The plan is an important step<br />

in determining the funding<br />

requirements for the next fiveyear<br />

period to 2024.<br />

It is something that Network<br />

Rail work alongside the Office<br />

of Rail and Road (ORR) with, in<br />

order to determine the level of<br />

funding needed to deliver the<br />

necessary improvements.<br />

The ORR has spoken about<br />

the process of this periodic<br />

review, what is expected of<br />

Network Rail in terms of putting<br />

their contracts in place for<br />

improvements in CP6.<br />

The regulator will now review<br />

the Strategic Business Plan and<br />

make a draft determination in<br />

June, with a final decision made<br />

in the autumn.<br />

Network Rail’s expenditure<br />

plans on their operations<br />

for the five years to 2024 in<br />

the Strategic Business Plan,<br />

which will see a 25% increase<br />

in funding from the current<br />

control period in order to<br />

improve infrastructure reliability<br />

by way of maintenance,<br />

operations and renewals.<br />

A further £10 billion railway<br />

enhancement fund has been<br />

made available by the government<br />

for any projects on the railways<br />

that are delivered by Network Rail<br />

or other contractors.<br />

Mark Carne, Chief Executive<br />

who is stepping down in<br />

time for CP6, explains what<br />

the Strategic Business Plan<br />

outlines.<br />

“Passenger journeys will be<br />

transformed in the next few<br />

years as thousands of new<br />

trains enter service. By 2021,<br />

there will be almost 350,000<br />

more services per year than<br />

today – an average of an extra<br />

1,000 services a day, better<br />

connecting communities and<br />

driving economic growth<br />

across the country.<br />

“This plan builds on these<br />

improvements and sets out<br />

how we will make the railway<br />

more reliable and cost efficient,<br />

and how we accelerate the<br />

technological transformation of<br />

our railway into the digital age.<br />

“It is an ambitious, but realistic<br />

plan that is not without<br />

challenge, but with great<br />

people working together in<br />

great teams, it can deliver the<br />

better railway that a better<br />

<strong>Britain</strong> needs.”<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

7

LATEST INDUSTRY NEWS<br />

//. CONSULTATION ON ROAD INVESTMENT STRATEGY<br />

2 WILL INFLUENCE FUTURE PROJECTS<br />

THE government’s consultation<br />

for Road Investment Strategy 2<br />

has now ended, and feedback<br />

is being analysed.<br />

It will help to form the<br />

proposals for the Strategic<br />

Road Network (SRN) and shape<br />

the current and future needs<br />

of England’s roads.<br />

The consultation ran from<br />

December until the first week<br />

of February, in order for the<br />

Department for <strong>Transport</strong> (DfT)<br />

to gain the views set out for<br />

Road Investment Strategy in<br />

the initial SRN report; whether<br />

or not the analysis of approach<br />

for developing the new strategy<br />

is robust enough; and whether<br />

or not the government has<br />

heard the full range of views<br />

about the SRN.<br />

The initial report, from which<br />

consultation was sought,<br />

set out Highways England’s<br />

assessment of the state of the<br />

SRN as it currently stands, the<br />

potential and future needs, and<br />

proposed priorities for Road<br />

Investment Strategy 2.<br />

It is based on extensive<br />

research, and will form the<br />

basis of the next five-year spell<br />

of investment on the roads.<br />

Since the inception of Highways<br />

England in 2015, the first Road<br />

Investment Strategy – worth<br />

£15 billion – has made great<br />

strides in upgrading our roads,<br />

which identified 127 major<br />

schemes to start in the period<br />

between 2015 to 2020.<br />

Road Investment Strategy 2 will<br />

focus on the five years from<br />

2020, continuing the trend<br />

of improvements thanks to a<br />

greater investment, which is<br />

expected to be close to £30<br />

billion.<br />

Highways England has set<br />

out its priorities for the next<br />

investment strategy period in<br />

the initial SRN report.<br />

Priorities include a continuation<br />

of the focus on operations,<br />

maintenance and renewals;<br />

the rollout of expressways;<br />

the transformational<br />

investments that are required;<br />

an investment programme<br />

that only concentrates on<br />

large projects – instead, a split<br />

in focus so that small and<br />

medium schemes are given<br />

priority.<br />

The government-owned<br />

company will also ramp up the<br />

work on smart motorways, with<br />

the aim to make these “the<br />

spine of the network.”<br />

Already, we have seen many<br />

major projects roll out the use<br />

of smart motorways, with the<br />

M60 in Manchester, and M62 in<br />

Yorkshire just two of the major<br />

roads benefiting from this<br />

type of motorway that reduces<br />

journey times and congestion.<br />

This is to continue as Highways<br />

England prepare for the future,<br />

and the response to the DfT’s<br />

public consultation on this<br />

report will be published later<br />

in the year, informing on the<br />

next steps for Road Investment<br />

Strategy 2.<br />

8 TRANSPORT BRITAIN • APRIL 2018

LATEST INDUSTRY NEWS<br />

//. MARK CARNE TO STEP DOWN AS CHIEF<br />

EXECUTIVE OF NETWORK RAIL<br />

NETWORK Rail’s Chief<br />

Executive, Mark Carne, has<br />

announced his intention to<br />

retire before the end of the<br />

year.<br />

After joining the organisation in<br />

2014, he has been integral in<br />

Network Rail’s reclassification<br />

into a public sector company.<br />

Mark Carne has been<br />

instrumental in the<br />

transformational change in<br />

Network Rail, and this is evident<br />

in the regulatory structure of<br />

the organisation.<br />

In addition, some of the<br />

company’s biggest ever<br />

projects have been delivered<br />

under the stewardship of Mark<br />

Carne, including the Great<br />

North Rail Project which is<br />

ongoing and the opening of the<br />

iconic London Bridge station.<br />

Mr Carne informed the Board<br />

of his decision at this time so<br />

that a replacement will be in<br />

the role in time for the start<br />

of the next regulatory period<br />

in April 2019, the planning<br />

for which is currently well<br />

underway in conjunction with<br />

the Office of Rail and Road<br />

(ORR).<br />

And the outgoing Chief<br />

Executive confirmed the<br />

reason for the timing of his<br />

announcement.<br />

He said: “<strong>Britain</strong>’s railways<br />

matter to the lives of millions<br />

of people. The men and<br />

women who run the railway<br />

are enormously committed<br />

and it has been a privilege<br />

to lead the organisation at a<br />

time of huge investment and<br />

transformational change.<br />

“I planned the timing of my<br />

announcement so there was<br />

stability while we developed the<br />

business plan for the next five<br />

year regulatory period, but so<br />

that there will also be enough<br />

time for my successor to be<br />

firmly in place when it starts.<br />

“I leave knowing that the<br />

railway is in good hands and<br />

has a great plan for the future.”<br />

The <strong>Transport</strong> Secretary, Chris<br />

Grayling, paid tribute to Mr<br />

Carne.<br />

He said: “Mark has done an<br />

excellent job as Chief Executive<br />

of Network Rail, presiding over<br />

the biggest modernisation of<br />

our rail infrastructure since<br />

Victorian times.<br />

“I hope he will continue to<br />

play an important part in the<br />

transport sector in the future.”<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

9

LATEST INDUSTRY NEWS<br />

//. AIA ROAD MAINTENANCE REPORT<br />

HIGHLIGHTS PROBLEMS WITH POTHOLES<br />

A report from the Asphalt<br />

Industry Alliance (AIA) has<br />

highlighted the problem Great<br />

<strong>Britain</strong> has with potholes on<br />

its roads, which are becoming<br />

more difficult to fix.<br />

The Annual Local Authority<br />

Road Maintenance Survey<br />

(ALARM) – the 23rd edition of<br />

the report – gives a flavour of<br />

the general condition of the<br />

local road network.<br />

It reveals that local authorities<br />

have identified in excess of<br />

24,000 miles of road that will<br />

need essential maintenance in<br />

the next year.<br />

This is a worry for all road<br />

users, and we have already<br />

seen the detrimental effect<br />

that poor-conditioned road<br />

networks can have on the<br />

highways after the Road<br />

Haulage Association called for<br />

greater investment to fix the<br />

numerous potholes that can<br />

be found throughout Great<br />

<strong>Britain</strong>.<br />

The AIA’s report reveals<br />

the major problem with<br />

maintaining the road<br />

network: the annual shortfall<br />

in the budget to fix <strong>Britain</strong>’s<br />

carriageways. In the 2018<br />

report, this is at £555.7 million,<br />

which illustrates the constraints<br />

that councils face in the fight to<br />

maintain the road network to a<br />

standard fit for motorists and<br />

businesses.<br />

The shortfall in annual<br />

carriageway maintenance<br />

budget per local authority<br />

is £3.3 million, and the time<br />

estimated to clear the backlog<br />

of maintenance has increased<br />

to 14 years.<br />

With the poor weather in the<br />

first quarter of the year, this<br />

problem is only set to get<br />

worse, as snow and ice tend to<br />

loosen the carriageways.<br />

The average highway<br />

maintenance budget per<br />

authority went up from last<br />

year’s report to £20.6 million,<br />

and the average carriageway<br />

maintenance budget also rose.<br />

However, the percentage of<br />

highway maintenance budget<br />

spent on the carriageways<br />

has decreased. The AIA report<br />

highlights that the percentage<br />

of local authority budget is<br />

decreasing at a time it ought to<br />

be on the rise.<br />

Nicholas Lyes, RAC head of<br />

roads policy, said: “It’s time<br />

for some fresh thinking when<br />

it comes to finally getting<br />

on top of <strong>Britain</strong>’s pothole<br />

problem. Short term funding<br />

and creating pots by which<br />

local authorities can bid for<br />

cash doesn’t appear to be<br />

addressing the root cause of<br />

the problem.<br />

“Instead, the government<br />

should be looking at how it<br />

can guarantee councils the<br />

certainty of reliable long term<br />

funding so they can finally bring<br />

every road up to a standard<br />

road users think is acceptable.”<br />

10 TRANSPORT BRITAIN • APRIL 2018

. BALFOUR BEATTY ANNOUNCE THIRD<br />

PARTIAL SALE OF ITS CONNECT PLUS HOLDING<br />

INTERNATIONAL<br />

infrastructure firm Balfour<br />

Beatty has announced a third<br />

partial sale of its stake in<br />

Connect Plus.<br />

The expected profit on this<br />

particular transaction, which<br />

will see a further 5% stake<br />

sold in the organisation that is<br />

responsible for operating the<br />

M25 orbital motorway, will pay<br />

down borrowings for this year.<br />

Balfour Beatty confirmed this<br />

sale is for a cash consideration<br />

of £42 million, which is more<br />

than the valuation set by the<br />

Directors at the end of June<br />

2017.<br />

It is quite a shift in policy for<br />

the company; at the start of<br />

December, Balfour Beatty had<br />

a 40% stake in Connect Plus<br />

– which is a consortium that<br />

consists of Balfour Beatty, Egis<br />

Road Operation UK and Edge<br />

Orbital Holdings Ltd. These<br />

organisations work together<br />

to deliver highways asset care<br />

from finance and design, to<br />

build and maintenance, along<br />

with day-to-day operation.<br />

However, at the end of last<br />

year, Balfour Beatty announced<br />

two partial sales of its stake<br />

in Connect Plus: the first was<br />

for 12.5% of its sake, worth<br />

£103 million, and the second<br />

saw a further 7.5% of the<br />

stake relinquished for a cash<br />

consideration of £62 million<br />

– again, higher than the initial<br />

valuations made by company<br />

Directors last June.<br />

Now, with the sale of a further<br />

5%, it means Balfour Beatty<br />

has sold 25% of its original<br />

40% holding, for a total cash<br />

consideration of £207 million.<br />

The Group confirmed that the<br />

latest 5% was sold to funds<br />

managed by Equitix Investment<br />

Management Ltd (Equitix), who<br />

has also exercised an option on<br />

the 7.5% partial sale, meaning<br />

that the 25% sold by Balfour<br />

Beatty has been split evenly by<br />

Dalmore Capital Ltd and Equitix.<br />

The Chief Executive of Balfour<br />

Beatty, Leo Quinn, said the<br />

partial sale of its Connect Plus<br />

stake reflects the Group’s intent<br />

to its shareholders.<br />

He said: “This transaction<br />

again demonstrates the<br />

ongoing attractiveness of<br />

our infrastructure assets and<br />

is in line with our declared<br />

intent to maximise value for<br />

shareholders.”<br />

Balfour Beatty still owns 15% of<br />

Connect Plus.

LATEST INDUSTRY NEWS<br />

//. £3 BILLION INVESTMENT CONFIRMED<br />

FOR UPGRADES ON TRANSPENNINE ROUTE<br />

A £3 billion programme of<br />

upgrades on the Transpennine<br />

route will begin next year,<br />

according to the <strong>Transport</strong><br />

Secretary.<br />

Chris Grayling was speaking in<br />

Leeds about the project, which<br />

while already underway on<br />

routes between Manchester,<br />

Liverpool and York, will also<br />

receive this further investment<br />

from Network Rail for “an<br />

ambitious rolling programme of<br />

works.”<br />

The <strong>Transport</strong> Secretary was at<br />

the <strong>Transport</strong> for the Northern<br />

Powerhouse conference,<br />

which is just one step that<br />

northern leaders want to see<br />

implemented to improve the<br />

region’s transport.<br />

He said that the government<br />

will work alongside Network Rail<br />

and local authorities along the<br />

Transpennine route so that the<br />

£3 billion investment can be<br />

maximised by way of creating<br />

stations, increasing access to the<br />

railway and unlocking housing<br />

opportunities.<br />

In addition, the subject of<br />

Crossrail 2 came up at the<br />

conference, with the <strong>Transport</strong><br />

Secretary confirming an<br />

Independent Affordability Review<br />

commissioned by <strong>Transport</strong> for<br />

London and the Department for<br />

<strong>Transport</strong>, which will ensure that<br />

affordability and value for money<br />

to the taxpayer is demonstrated<br />

throughout Crossrail 2.<br />

It is a topic of much debate;<br />

last year saw an agreement<br />

made to move forward with<br />

Crossrail 2, but it is something<br />

that the Mayors of Greater<br />

Manchester and the Liverpool<br />

City Region questioned because<br />

they were concerned that the<br />

north was neglected in favour of<br />

investment for this railway.<br />

It is hoped the £3 billion<br />

investment for the Transpennine<br />

route shows the necessary<br />

commitment to railways in<br />

the north, and also improves<br />

passenger and business<br />

experience of travelling in these<br />

areas.<br />

Mr Grayling said: “I want to<br />

realise passenger benefits from<br />

the £3 billion we have ringfenced<br />

for the Pennine route as<br />

fast as possible.<br />

“Network Rail has already<br />

begun detailed designs, and<br />

provided us with options for the<br />

Transpennine Route Upgrade<br />

to meet the objectives we’ve set<br />

out – for journey times, capacity<br />

and reliability.<br />

“That – in turn – has given us an<br />

opportunity to undertake the<br />

work in phases starting as soon<br />

as spring next year.<br />

“This is not just about meeting<br />

rising demand for train travel.<br />

It’s about transforming journeys<br />

too.”<br />

12 TRANSPORT BRITAIN • APRIL 2018

LATEST INDUSTRY NEWS<br />

//. TRANSPORT SECRETARY PUBLISHES<br />

RESPONSE TO HS2 CREWE HUB CONSULTATION<br />

THE <strong>Transport</strong> Secretary has<br />

published his consultation<br />

response for how HS2 will<br />

improve connectivity of the<br />

Crewe Hub.<br />

The consultation, which ran<br />

from July to October last year,<br />

sought views on the options<br />

that could improve Crewe’s –<br />

and the surrounding region’s<br />

– access to both conventional<br />

and high speed rail services.<br />

Comments were sought on<br />

the vision for a hub station in<br />

Crewe, as well as infrastructure<br />

options for enabling more HS2<br />

services to stop in the area.<br />

Chris Grayling spoke to the<br />

House of Commons about<br />

how the plans have changed in<br />

response to the consultation<br />

which outlines how the vision<br />

of a Crewe Hub will enable<br />

additional HS2 services to<br />

Stoke-on-Trent.<br />

As part of the response to the<br />

consultation, the <strong>Transport</strong><br />

Minister confirmed plans<br />

for HS2 Phase 2A from<br />

Birmingham to Crewe which<br />

will now see 400-metre<br />

platforms built in Crewe.<br />

These will allow longer HS2<br />

trains to split and join, which<br />

in turn will ensure more<br />

destinations are served. It also<br />

meets the government’s aims<br />

of ensuring more people have<br />

access to HS2.<br />

The government believe a<br />

Crewe Hub will generate job<br />

opportunities for the town and<br />

surrounding area; through<br />

the consultation, steps will be<br />

taken to make sure Crewe and<br />

Stoke-on-Trent can benefit<br />

from high speed rail and will<br />

build on the previous decision<br />

to ensure Crewe benefits from<br />

HS2 in 2027 – which is six years<br />

earlier than initially planned.<br />

In response to the consultation,<br />

Mr Grayling said: “We welcome<br />

the progress being made by<br />

Cheshire East Council and the<br />

local enterprise partnership<br />

in identifying how they could<br />

invest in the scheme to ensure<br />

the benefits are fully realised.”<br />

He ended his response in<br />

the Commons by reiterating<br />

HS2’s role as the “backbone”<br />

of the rail network, which will<br />

also support the government’s<br />

Industrial Strategy that will<br />

generate economic growth and<br />

skills for the UK.<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

13

LATEST INDUSTRY NEWS<br />

//. COMMUNITIES IN BUCKINGHAMSHIRE<br />

TO BENEFIT FROM £450,000 OF<br />

GOVERNMENT’S HS2 FUND<br />

Buckinghamshire is the latest<br />

area to benefit from a grant as<br />

part of the delivery of HS2.<br />

The HS2 Minister, Nusrat<br />

Ghani, has announced that<br />

Wendover Woods Recreational<br />

Development project near<br />

Aylesbury in Buckinghamshire<br />

will be created thanks to a<br />

£450,000 grant.<br />

It is the latest and most<br />

significant investment for any<br />

single project up to now for<br />

the £40 million HS2 Phase One<br />

Community and Environment<br />

Fund (CEF), and Business and<br />

Local Economy Fund (BLEF).<br />

This funding, part of a £45<br />

million investment from the<br />

government, will benefit<br />

community projects along the<br />

HS2 route and provide a legacy<br />

of improvements.<br />

The extra £5 million will benefit<br />

communities along HS2 Phase<br />

2a route from Midlands to<br />

Crewe.<br />

Thanks to this £450,000 funding,<br />

Wendover Woods will benefit<br />

from a new woodland hub,<br />

adventure trail, cafe and parking<br />

for 600 visitors.<br />

As well as this development<br />

in Buckinghamshire, the<br />

investment will support a<br />

range of projects such as<br />

refurbishment of community<br />

centres and nature conservation.<br />

Not only will this help with the<br />

preservation of the area, but will<br />

also drive the economy in these<br />

local areas, bringing businesses<br />

and jobs.<br />

Ms Ghani visited the site where<br />

this new woodland hub will be<br />

built. She is excited about the<br />

projects that will come to fruition<br />

in the coming years thanks to<br />

the funds.<br />

“HS2 will be the backbone<br />

of our national rail network<br />

– supporting growth and<br />

regeneration and helping us<br />

build a <strong>Britain</strong> fit for the future.<br />

“Whilst we know there will be<br />

disruption as we deliver one of<br />

Europe’s biggest infrastructure<br />

projects, we are absolutely<br />

committed to minimising the<br />

effects of building the new<br />

railway.<br />

“It is great to see so many<br />

local projects such as the<br />

Wendover Woods recreational<br />

development project benefit<br />

from this fund, helping even<br />

more people access and enjoy<br />

our beautiful countryside.<br />

“Funding such as CEF and<br />

BLEF will help to ensure that<br />

the legacy of HS2 is shared by<br />

everyone for generations to<br />

come.”<br />

14 TRANSPORT BRITAIN • APRIL 2018

. LENDLEASE TO REDEVELOP LONDON<br />

EUSTON STATION IN PREPARATION FOR HS2<br />

LENDLEASE has been awarded<br />

the contract to redevelop<br />

London Euston station in<br />

preparation for the arrival of<br />

HS2 services.<br />

The multinational construction<br />

company was responsible for<br />

the iconic Athletes’ Village for<br />

the London 2012 Olympics<br />

and subject to the signing of<br />

contracts, will be appointed<br />

Master Development Partner.<br />

The company will work<br />

alongside the Greater London<br />

Authority and the London<br />

Borough of Camden to deliver<br />

a transformed London Euston<br />

on a 54-hectare site in and<br />

around the new station.<br />

In a recurring theme for<br />

HS2, this contract promises<br />

to deliver jobs and homes;<br />

approximately 19,000 jobs<br />

could be generated around<br />

the station site, while up to<br />

1,700 homes could be built<br />

as a result of the station<br />

redevelopment.<br />

Dan Labbad is the Chief<br />

Executive Officer International<br />

Operations for Lendlease. He<br />

said this ‘game changing’ project<br />

fits neatly with the company<br />

ethos of projects targeted.<br />

He said: “The redevelopment<br />

of Euston stands to be a real<br />

gamechanger for commuters<br />

across London and the UK.<br />

“Euston will be much more<br />

than a transport hub – and<br />

we’ll work closely with project<br />

partners to provide benefits to<br />

local people, foster business<br />

growth and deliver new homes.<br />

“This announcement is<br />

consistent with our stated<br />

strategy to grow our<br />

development pipeline in<br />

gateway cities and increasingly<br />

reallocate capital to our<br />

international operations.”<br />

The redevelopment is required<br />

given that HS2’s arrival in<br />

London will double the number<br />

of seats out of London during<br />

peak hours. This extra capacity<br />

with new access routes –<br />

making Euston one of the best<br />

connected parts of the country<br />

– needs the redevelopment to<br />

cater for the sheer size of the<br />

changes.<br />

As well as providing capacity<br />

for extra trains and unlocking<br />

homes, the project undertaken<br />

by Lendlease will comprise of<br />

commercial, retail, hotel and<br />

leisure spaces.<br />

More than a year since it was<br />

granted Royal Assent, phase<br />

one of HS2 is well underway<br />

and will provide a new<br />

connection from London to the<br />

West Midlands by 2026.<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

15

. APP SOLUTIONS ARE CHANGING<br />

THE WAY SURFACES ARE CLEANED<br />

Founded in the Netherlands more than 30 years ago, APP All Remove B.V has built up an enviable<br />

reputation of maintaining architectural beauty and integrity through its innovative solutions that<br />

remove graffiti and other vandalism on horizontal and vertical building surfaces.<br />

Business <strong>Britain</strong> spoke at length to Brigitta van Staveren, about the company’s products, its<br />

journey, and future expansion plans.<br />

Can you tell us a bit about<br />

the company and its origins?<br />

APP was founded in 1985, the<br />

brainchild of our current CEO’s<br />

father, Piet Nuijs. He started the<br />

business to clean, protect and<br />

maintain horizontal and vertical<br />

building surfaces.<br />

Initially, it was a case of<br />

purchasing products to try and<br />

keep the surfaces and built<br />

environment clean. Along the<br />

way, we started to cooperate<br />

with different organisations to<br />

try and find a way to produce<br />

our own protective coatings.<br />

Now, we have our own product<br />

engineers, we take care of our<br />

own production and shipping<br />

around the world. Our product<br />

engineer tries to develop one or<br />

two new products a year, which<br />

is something we strive for, and<br />

we have our own laboratory to<br />

do this, which has produced<br />

three mainline coating<br />

products.<br />

What we do with the coatings<br />

we have is get them to the<br />

various surfaces. For example,<br />

if you have a concrete surface<br />

and want a special finish to<br />

it, we can adapt our coating<br />

to that finish. That is what we<br />

do; we can create tailor-made<br />

products for each client and<br />

organisation.<br />

The impregnation for horizontal<br />

surfaces and the permanent<br />

anti-graffiti have also evolved<br />

along the way, becoming more<br />

and more apt to protect all<br />

kinds of architectural surfaces<br />

from pollution.<br />

In our privately-owned<br />

laboratory in Beers, the<br />

Research & Development<br />

department is engaged in<br />

research, product and process<br />

development and provides<br />

technical support to our<br />

customers.<br />

To do so we are supported<br />

by teams of scientists and<br />

engineers from various national<br />

and international universities<br />

16 TRANSPORT BRITAIN • APRIL 2018

and knowledge institutions in<br />

the particular field of surface<br />

protection.<br />

In this way we are well<br />

organised to provide the<br />

knowledge and the skill for<br />

customer-oriented research<br />

and advice. Specific product<br />

features for individual projects<br />

and new products and<br />

processes can be extensively<br />

tested to optimise end<br />

products.<br />

How did you get involved<br />

with markets outside of the<br />

Netherlands?<br />

We had a lot of projects at<br />

the start; one of the biggest<br />

and largest projects was the<br />

protection of the sound walls<br />

of the train track that crosses<br />

Rotterdam to Germany. It had<br />

sound barriers of concrete that<br />

were like a canvass for graffiti.<br />

They had to be protected and<br />

since we’ve been doing this<br />

since 1985 we were granted the<br />

tender and protected them.<br />

The concrete sound wall wasn’t<br />

along the whole track - but<br />

where the rail track passes<br />

cities. These sound barriers<br />

were protected with our<br />

products. Once we protected<br />

them, they were defaced with<br />

graffiti, which our engineers<br />

removed – together with the<br />

coating – and then we applied<br />

another layer of coating. That<br />

is how we provide protection<br />

as a way of working, even since<br />

1985!<br />

We have seven fully-fledged<br />

teams in the Netherlands,<br />

one of which is always near<br />

a potential customer. When<br />

people call to say they have<br />

graffiti on their walls, we remove<br />

this within five days, unless it is<br />

extremely offensive language,<br />

in which case this will be gone<br />

within 24 hours thanks to our<br />

contemporary market approach<br />

that offers customers problemsolving<br />

concepts.<br />

What do you feel you have<br />

been able to offer the UK<br />

market that nobody else<br />

can?<br />

We are not yet in the UK<br />

market but we have a very<br />

close relationship with a<br />

Belgian concrete producer,<br />

and this company produces<br />

architectural concrete that is<br />

used in the UK. It was used on<br />

the Athletes Village for the 2012<br />

Olympics in London, and these<br />

concrete frames were protected<br />

in the factory in Belgium with<br />

a solution that was developed<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

17

specifically for new concrete.<br />

Usually, you can only protect<br />

concrete after 28 days because<br />

it has to be secure first, but this<br />

solution we have developed can<br />

be used on concrete right after<br />

de-casting it. This makes it very<br />

easy to keep frames clean, even<br />

after installation.<br />

For the UK specifically, we feel<br />

we are ideally placed because of<br />

our track record in developing<br />

and producing functional<br />

coatings that protect the built<br />

environment.<br />

We develop and produce<br />

functional coatings that<br />

protect the built environment.<br />

Architects demand that their<br />

creations are delivered CLEAN.<br />

But how to achieve that when<br />

there is always oil, chewing gum,<br />

urine, water, exhaust gases,<br />

graffiti and soot?<br />

APP creates impregnations<br />

that can be used to protect<br />

most kind of building materials<br />

against these pollutions. Our<br />

in-house developed products<br />

do not change the visual or<br />

physical properties of the everinnovative<br />

building materials.<br />

Our impregnation for<br />

horizontal surfaces transforms<br />

porous substrates into ultrahydrophobic<br />

and oleophobic<br />

supersurfaces that repel water,<br />

oil-based contaminants and<br />

other stains. It is environmentally<br />

friendly, water based, vapour<br />

permeable and zero-VOC. The<br />

surface is protected and without<br />

change; it is completely invisible.<br />

Our semi-permanent and<br />

BIOBASED anti-graffiti system<br />

provides an efficient and<br />

weather resistant protection<br />

against graffiti. A mix of 100%<br />

natural polysaccharides and<br />

water. After drying it forms<br />

an extremely thin, invisible,<br />

protective film and leaves the<br />

surface completely vapour<br />

permeable. Graffiti is easily<br />

removed without the use of any<br />

harsh products; just hot water!<br />

Our coatings protect various<br />

commercial, civil engineering<br />

and infrastructure projects, art<br />

and heritage against graffiti, oil,<br />

chewing gum, urine, exhaust<br />

fumes and soot.<br />

In this way we offer a solution<br />

for the cleaning and keeping<br />

clean various architectural<br />

surfaces. Our protective<br />

systems are suitable for the<br />

ever-innovative materials used<br />

in construction, production<br />

facilities, architectural buildings,<br />

food industry, retail and<br />

automotive production and<br />

communication industry.<br />

Could you give us an idea of<br />

the sectors your clients are in?<br />

We have a wide range of clients<br />

including companies that<br />

undertake building maintenance,<br />

owner associations of flat<br />

buildings; infrastructure builders;<br />

general construction companies;<br />

façade maintenance companies;<br />

we have a lot of managers of<br />

shopping centres that are clients<br />

of ours, but they are individual<br />

clients. We also could be looking<br />

for an agent or distributor.<br />

There are lots more, and we<br />

work alongside municipality,<br />

province and government<br />

authorities.<br />

How many countries do you<br />

have clients in?<br />

Our expertise are used in so<br />

many countries, including the<br />

United States, Australia, Turkey,<br />

France, Cyprus, Spain, Germany,<br />

Poland, Czech Republic. We<br />

have a client in Indonesia,<br />

Portugal, Ireland, Sweden,<br />

18 TRANSPORT BRITAIN • APRIL 2018

Norway, to give you an idea.<br />

How do you get your<br />

products to these places?<br />

It’s done by always networking.<br />

We visit fares, we put fares on<br />

where people visit us, and word<br />

of mouth has served us well.<br />

That is the way we have been<br />

able to enlarge our network,<br />

and also with our products,<br />

which are very well known.<br />

People searching on Google<br />

will always be directed to our<br />

company.<br />

What is your strategy for<br />

acquiring clients, and what<br />

is it about your service that<br />

your clients like?<br />

The service clients are looking<br />

for is to make sure they use<br />

less man hours and cleaning<br />

products to keep their surfaces<br />

clean. This is something we can<br />

provide with our impregnations<br />

which can protect floors, any<br />

mineral surface etc, from<br />

pollution.<br />

Anything such as spillages in<br />

restaurants, you can protect<br />

these floors from penetration of<br />

the dirt. You can still clean them<br />

but it will be easier, quicker,<br />

and you’ll need less products to<br />

clean them.<br />

This also counts for the outside<br />

of buildings too; you can protect<br />

them against graffiti. I know<br />

there are lots of anti-graffiti<br />

products in the UK, such as<br />

wax-based products.<br />

That is very good because<br />

you can apply that wax-based<br />

product which will protect a<br />

surface for 5-7 years, and any<br />

anti-graffiti removal products<br />

will take graffiti off the wax.<br />

The wax though, needs using<br />

90°C water and 150bar to be<br />

removed; this may seriously<br />

damage a surface.<br />

The good thing about our<br />

product is it’s a sacrificial<br />

product; you have to apply one<br />

layer, let it dry and then apply<br />

another layer. When there’s<br />

graffiti on it, you soak up the first<br />

layer until it comes off, together<br />

with the graffiti. You then apply<br />

another new layer so the surface<br />

is protected again.<br />

Then again, say an owner of a<br />

building wants the anti-graffiti<br />

removing because he wants a<br />

layer of paint on the outside, you<br />

can take all of this off the wall,<br />

which is something you cannot<br />

do with a wax-based product.<br />

We feel our product is<br />

something that the UK market<br />

can therefore thrive on, and<br />

we look to reach these clients<br />

by presenting ourselves at<br />

expositions and fairs, which we<br />

travel to all over the world.<br />

We also make use of the<br />

internet, networking tools such<br />

as LinkedIn, as well as word of<br />

mouth because of the success<br />

of our product.<br />

In your opinion, why do your<br />

products stand out from<br />

those of your competitors?<br />

Many companies use<br />

Polyurethane, silanes/siloxanes<br />

or wax for protection of<br />

surfaces. We prefer to use<br />

polysaccharides the building<br />

blocks of nature.<br />

This makes our functional<br />

coatings safe for the engineers<br />

that use them, biodegradable,<br />

easy to apply, graffiti resistant.<br />

The three products are:<br />

• Sacrificial anti-graffiti<br />

coating is what it says,<br />

sacrificial, if need be it<br />

can be COMPLETELY 100%<br />

REMOVED, and the surface<br />

will be left clean and ready<br />

for other treatments.<br />

Without the use of harsh<br />

chemicals, just warm<br />

water. This is why the Dutch<br />

Monument Care accepted<br />

this system for use on<br />

monuments and objects<br />

of art.<br />

Graffiti can be removed<br />

by the use of ONLY hot<br />

water and adapted<br />

pressure. It is completely<br />

damp-open or vapour<br />

permeable, and comes with<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

19

a warranty of anything<br />

between two to five years.<br />

• Permanent anti-graffiti<br />

coating can NOT BE taken<br />

off of the surface.<br />

Graffiti can be removed<br />

by the use of hot water<br />

and adapted pressure and<br />

a mild graffiti remover. Like<br />

the sacrificial anti-graffiti,<br />

this one is also vapour<br />

permeable and only needs<br />

to be applied once. It<br />

comes with a 10-year<br />

warranty.<br />

• Permanent impregnation<br />

for horizontal surfaces; this<br />

solution penetrates the<br />

pores right under the<br />

surface, making floors<br />

much easier to clean.<br />

Our permanent<br />

impregnation product can<br />

be used on the vast<br />

majority of mineral surfaces<br />

and comes with a warranty<br />

of at least five to eight<br />

years.<br />

All three of our base<br />

products are 100% invisible<br />

on any wall or floor, and<br />

they do not change the feel<br />

or texture of the surfaces<br />

they are applied to.<br />

What are your biggest<br />

challenges and what are<br />

your future plans?<br />

Expanding outside of the<br />

Netherlands is always a<br />

challenge. In this country,<br />

our daughter company<br />

GevelMeesters does all the<br />

work, but we have big plans<br />

on expanding outside of the<br />

Netherlands. We have large<br />

clients in Australia, the United<br />

States; and clients in in many<br />

European countries.<br />

Where we don’t have a fixed<br />

client however, is in the<br />

United Kingdom, and this is a<br />

marketplace we want to break<br />

into. We also want to break into<br />

the Russian market.<br />

Is there anything else you’d<br />

like to mention?<br />

We started in the Netherlands,<br />

but are rapidly growing in<br />

Europe and overseas. We want<br />

this growth to move into the UK<br />

market and believe we are well<br />

placed to do this because not<br />

only does APP sell products, but<br />

we also sell solutions too.<br />

Our team prides itself on<br />

offering a complete package<br />

of products and services<br />

solutions to our customers,<br />

complete with instructions<br />

and demonstrations by project<br />

engineers.<br />

20 TRANSPORT BRITAIN • APRIL 2018

In partnership with<br />

www .tcp. e u.com<br />

Powered by HYMERA<br />

R<br />

Bright thinking<br />

illuminating the future<br />

Hydrogen fuel cell lighting,<br />

surveillance and off-grid power<br />

helping to reduce carbon emissions<br />

Zero Emissions<br />

Zero CO<br />

Zero NO<br />

2<br />

X<br />

Section 61<br />

Compliant<br />

Virtually silent<br />

TCP160 (1) 0318<br />

MEMBER<br />

nqa<br />

ISO 9001<br />

Registered<br />

Quality<br />

Management<br />

015<br />

nqa<br />

ISO 14001<br />

Registered<br />

Environmental<br />

Management<br />

015<br />

ID: 000989<br />

REQUEST A TRIAL!<br />

0845 3717626

. STOPPING DIESEL BEYOND THE TRACKS. THE<br />

NEED FOR ‘CLEANER, GREENER’ RAIL IS VITAL<br />

IN a speech delivered by<br />

Minister in the Department<br />

for <strong>Transport</strong> and Minister for<br />

London, Jo Johnson, in February,<br />

pollution and carbon emissions<br />

were once again brought to the<br />

forefront of discussion; this time<br />

with the focus on the rail sector.<br />

Jo Johnson declared his<br />

ambition to see all diesel-only<br />

trains off the track by 2040<br />

stating that:<br />

“by decarbonising rail, we’ll<br />

reduce pollutants and improve<br />

air quality…”<br />

Jo Johnson gave particular<br />

mention to the consideration<br />

of hydrogen engines replacing<br />

battery and diesel in the future<br />

announcing that he would like<br />

to see ‘hydrogen train trials<br />

on the UK railway as soon as<br />

possible’ and continued by<br />

asserting that, ‘hydrogen offers<br />

an affordable and<br />

potentially much<br />

cleaner alternative to diesel’.<br />

But the notion of a<br />

decarbonised railway extends<br />

beyond the finished product,<br />

beyond the objective to replace<br />

all diesel-only trains, and looks<br />

further back down the track to<br />

the construction of our railways<br />

and the working practises to<br />

bring this ambition to fruition.<br />

As Jo Johnson said in his speech:<br />

‘the drive to decarbonise must<br />

come from all sectors of the<br />

industry’.<br />

22 TRANSPORT BRITAIN • APRIL 2018

The impetus to reduce<br />

carbon emissions in the rail<br />

construction sector has seen<br />

strong and steady drive over<br />

the last year with Crossrail now<br />

having set a target to reduce<br />

carbon footprint and reduce<br />

construction related energy<br />

by 8% which ‘equates to some<br />

30,000t of carbon saved during<br />

the construction phase on<br />

energy efficiency measures<br />

alone’.<br />

We are now all too aware of the<br />

alarming statistics surrounding<br />

the cost of air pollution to<br />

our society, with thousands<br />

upon thousands of premature<br />

deaths every year attributed<br />

to harmful emissions pumped<br />

into the air we breathe. The rail<br />

industry has already stepped up<br />

their response to this crisis by<br />

utilising some alternative hybrid<br />

and hydrogen fuelled plant on<br />

maintenance and construction<br />

projects around the capital<br />

and across the UK. In doing so,<br />

they have begun to significantly<br />

reduce emissions on sites thus<br />

benefiting the environment and<br />

consequently the occupational<br />

health of the workforce.<br />

Hydrogen fuel cell products<br />

like TCP’s Ecolite TH200 LED<br />

light tower and the Genie<br />

Eco CCTV tower - just some<br />

of TCP’s range which have<br />

already been put to use on<br />

projects such as Crossrail<br />

Anglia, Whitechapel and Hayes<br />

- both use BOC’s HYMERA®<br />

fuel cell as a sustainable power<br />

source and therefore provide<br />

a green energy solution. With<br />

no internal combustion engine<br />

or harmful emissions, products<br />

like these can be used in<br />

enclosed spaces such as tunnel<br />

work and provide solutions for<br />

environmentally sensitive areas<br />

where there must be zero risk<br />

of contamination.<br />

The Ecolite range is powered<br />

through a system in which<br />

hydrogen combines with<br />

oxygen (from the atmosphere)<br />

in a fuel cell, to produce<br />

electricity with the only emission<br />

being water vapour. This<br />

process is virtually silent which<br />

is important for work at night,<br />

in built-up residential areas and<br />

means users of the Ecolite fuel<br />

cell product range can easily<br />

comply to the section 61 noise<br />

pollution act.<br />

The possibilities of other<br />

clean air solutions within the<br />

rail construction sector are<br />

not limited to lighting and<br />

surveillance systems alone.<br />

TCP’s off-grid power supplies<br />

and mobile environmental work<br />

stations are among some of<br />

the other alternatives which<br />

have already been put into<br />

operation on projects within<br />

the industry resulting in the<br />

reduction of noise complaints<br />

and the opportunity to<br />

significantly cut back on the<br />

amount of diesel generators,<br />

and the consequential adverse<br />

environmental emissions.<br />

The use of hydrogen fuel cell<br />

replacements for diesel and<br />

petrol plant has seen a positive<br />

growth and with running costs<br />

for these hydrogen alternatives<br />

becoming ‘cost neutral’ against<br />

those of traditional diesel units,<br />

the appeal of hybrid, hydrogen,<br />

alternatives has become one<br />

that doesn’t ‘cost the earth’.<br />

With the successful<br />

implementation of hydrogen<br />

powered buses in some of our<br />

major cities, it’s time for the rail<br />

industry to follow suit. In his<br />

speech, Jo Johnson asked for<br />

the industry to report back by<br />

the autumn with a ‘clear long<br />

term strategy with consistent<br />

objectives and incentives’. It’s<br />

time to make tracks towards a<br />

greener, cleaner future for the<br />

rail industry.<br />

For more information on the<br />

hydrogen fuel cell range of<br />

products available from TCP Ltd,<br />

please contact us at ecolite@<br />

tcp.eu.com or call on 01621<br />

850777, with five depots across<br />

the UK we are able to supply<br />

nationwide.<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

23

LATEST INDUSTRY NEWS<br />

//. CROSSRAIL LTD RELEASE IMAGES<br />

THAT HIGHLIGHT ELIZABETH LINE<br />

CONSTRUCTION PROGRESS<br />

CROSSRAIL Ltd has released a<br />

series of images that highlight<br />

the progress of work to deliver<br />

the Elizabeth line.<br />

London’s newest railway – 73<br />

miles in length – will connect<br />

the capital to the home<br />

counties, with 10 new stations<br />

constructed to service the<br />

Elizabeth line.<br />

The project has made<br />

great strides in the last<br />

year; Crossrail Ltd recently<br />

confirmed more than 90% of<br />

the project is now complete.<br />

To mark this level of progress,<br />

the series of images highlight<br />

the progress made on the<br />

construction part of this huge<br />

infrastructure project which is<br />

now in its final stages.<br />

Elizabeth line stations are<br />

now being fitted out and only<br />

recently, the first train was<br />

driven through the tunnels,<br />

with other tests to come.<br />

Images include those of<br />

Paddington station’s 21-metre<br />

long escalators; Bond Street<br />

western ticket hall which<br />

will lead passengers to the<br />

platforms 28 metres below<br />

ground; Whitechapel station’s<br />

striking framework is also<br />

profiled, where the integrated<br />

ticket hall will be located.<br />

The images released by<br />

Crossrail Ltd also display the<br />

Old Oak Common depot,<br />

complete with a view of the<br />

stunning new fleet of trains,<br />

which will be maintained at the<br />

depot.<br />

Howard Smith is the<br />

Operations Director for the<br />

Elizabeth line. He is excited at<br />

the vision of these ‘dynamic’<br />

spaces.<br />

“Seeing our striking new<br />

stations take shape is an<br />

extremely exciting time for<br />

all involved in the historic<br />

Elizabeth line project. We<br />

look forward to opening<br />

these dynamic new spaces to<br />

Londoners and visitors when<br />

we launch the railway in nine<br />

months’ time.”<br />

Andrew Wolstenholme, Chief<br />

Executive of Crossrail, added:<br />

“After almost a decade of hard<br />

work from tens of thousands<br />

of men and women across the<br />

country, the construction of the<br />

Elizabeth line has entered its<br />

final stages.<br />

“This fantastic set of new<br />

images shows the huge<br />

amount that has been<br />

achieved.”<br />

24 TRANSPORT BRITAIN • APRIL 2018

LATEST INDUSTRY NEWS<br />

//. ELIZABETH LINE TRAIN DRIVEN THROUGH<br />

NEW TUNNELS FOR THE FIRST TIME<br />

THE first Elizabeth line train<br />

has undergone testing in the<br />

brand new tunnels through<br />

London.<br />

A significant milestone, the<br />

train was driven from Abbey<br />

Wood into the new tunnels<br />

at Plumstead Portal and<br />

under the Thames towards<br />

the Connaught Tunnel before<br />

returning to the station.<br />

With less than a year until<br />

the new rail line opens in<br />

London – one of the biggest<br />

infrastructure projects in<br />

Europe – testing is the next<br />

step to ensure that the line is<br />

ready.<br />

Built by Bombardier engineers<br />

in Derby, the test run of the<br />

Elizabeth line train is the first<br />

of hundreds that will take place<br />

between now and December<br />

2018.<br />

This latest milestone –<br />

coming hot on the heels of<br />

confirmation that the project<br />

is more than 90% complete<br />

– is the start of a rigorous<br />

testing process of the railway<br />

and signalling infrastructure<br />

to make sure that safe and<br />

reliable services are in place<br />

once this Elizabeth line<br />

train and others like it are<br />

operational.<br />

The Elizabeth line also supports<br />

the draft <strong>Transport</strong> Strategy<br />

outlined by the Mayor of<br />

London that wants to improve<br />

public transport and reduce<br />

reliance on car journeys.<br />

Howard Smith is the<br />

Operations Director for the<br />

Elizabeth line, which will be run<br />

by <strong>Transport</strong> for London (TfL).<br />

He is “thrilled” that testing has<br />

started.<br />

He said: “This is a huge<br />

milestone for the project,<br />

nine years after construction<br />

first began. I’m thrilled to<br />

see the first train make its<br />

maiden voyage from Abbey<br />

Wood through the brand new<br />

tunnels.<br />

“Crucial testing is now<br />

underway to validate the<br />

safety and reliability of the<br />

Elizabeth line ahead of the<br />

launch. We look forward to<br />

welcoming customers onto our<br />

new railway this December,<br />

when their experience of<br />

travelling across London will be<br />

transformed for the better.”<br />

As the year goes on, signage<br />

will be installed in stations<br />

serviced by Crossrail, and the<br />

interior work at these locations<br />

will also be completed.<br />

APRIL 2018 • TRANSPORT BRITAIN<br />

25

INNOVATION WITH<br />

PURPOSE: BOSS CABINS<br />

EXPLAINS HOW ITS<br />

SOLUTIONS HELP THE<br />

INDUSTRY.<br />

Established in 2010, Boss Cabins<br />

is the market leader in the<br />

manufacturing of welfare cabins.<br />

The company’s Managing Director,<br />

Matthew Wordsworth, explains<br />

how the aims of Boss Cabins result<br />

in the creation of products and<br />

solutions for industries, and how<br />

innovation is driven.<br />

At Boss Cabins, we have a simple<br />

saying that runs through the core<br />

of our business and everything our<br />

customers can expect: we don’t<br />

innovate for the sake of it.<br />

This might sound cliched, but it’s<br />

entirely true. Since our inception in<br />

2010, we’ve become the market leader<br />

in the design, build and manufacture<br />

of mobile and static welfare cabins.<br />

Industries far and wide have been<br />

able – and have the potential – to<br />

benefit greatly from the solutions we<br />

can offer. We have experience working<br />

in markets as varied as construction,<br />

haulage, healthcare and agriculture.<br />

Our welfare cabins are used in<br />

government contracts, the highways<br />

and rail industries, where we offer<br />

solutions that are not only safe, but<br />

hugely efficient.<br />

That final point goes back to our<br />

mantra of innovation; in an era where<br />

organisations are trying to achieve greater<br />

efficiency, we’ve brought a product to the<br />

market which does just that.

Our Eco Ultimate provides the<br />

user with huge financial savings<br />

because the generators use<br />

much less energy. This also<br />

achieves the aim of reducing<br />

emissions, as less diesel is<br />

burned too.<br />

It is a system that would<br />

bring much greater levels of<br />

productivity for projects in<br />

highways and rail.<br />

The Eco Ultimate is the next<br />

level of fuel efficiency because,<br />

instead of continually using<br />

energy, we offer something that<br />

is completely functional but is<br />

intelligent enough to only use<br />

electricity and fuel when they<br />

are required.<br />

In previous years, you would<br />

see generators that are<br />

approximately 7kva. Our system<br />

has halved this, while ensuring<br />

that everything within the<br />

cabin such as hot water and<br />

electricity, work just as before.<br />

It means that a generator can<br />

turn itself on and off on demand,<br />

prioritising the appliances that<br />

are used for electricity.<br />

We wanted to create a cabin<br />

that is as user friendly as<br />

a house; our Eco Ultimate<br />

achieves this because the<br />

customer doesn’t have to think<br />

of energy usage – the system is<br />

smart enough to do that itself.<br />

Based on our field testing, the<br />

unit costs approximately 56p<br />

to run each day – a significant<br />

saving, and a groundbreaking<br />

system for the welfare industry,<br />

which can improve fuel<br />

efficiency by up to 75%. The<br />

efficiency really is through the<br />

roof.<br />

The Eco Ultimate system – like<br />

all of our welfare cabins –<br />

has been brought to market<br />

because it is a way of innovating<br />

to solve a problem.<br />

As a company, we know that we<br />

can’t always get things right, but<br />

what our clients can absolutely<br />

expect is that they’ll never be<br />

let down. We stand behind the<br />

quality of these products, which<br />

are backed by more than 50<br />

years of industry experience,<br />

and seek to find the solution<br />

that fits the needs of each and<br />

every client.<br />

And through our commitment<br />

to innovation to make a<br />

different, at Boss Cabins, we’re<br />

confident we will continue to<br />

make our customers happy.

. SERIES OF MILESTONES HIT BY NETWORK<br />

RAIL ON ELIZABETH LINE ROUTE<br />

MILESTONES on the Crossrail<br />

project have been reached<br />

after it was announced<br />

railway upgrades have been<br />

completed on the Elizabeth line<br />

route.<br />

Network Rail has undertaken<br />

the work at Pudding Mill Lane,<br />

Plumstead and Westbourne<br />

Park, while Gidea Park sidings<br />

have been improved so that full<br />

length Elizabeth line trains can<br />

be accommodated.<br />

In another of a series of<br />

milestones on Crossrail,<br />

signalling between Pudding<br />

Mill Lane to Shenfield has been<br />

updated in order to support<br />

Elizabeth line services.<br />

These upgrades are key in<br />

guaranteeing the railway<br />

infrastructure is in place by<br />

December 2018 when the first<br />

Elizabeth line services will run<br />

in London.<br />