Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

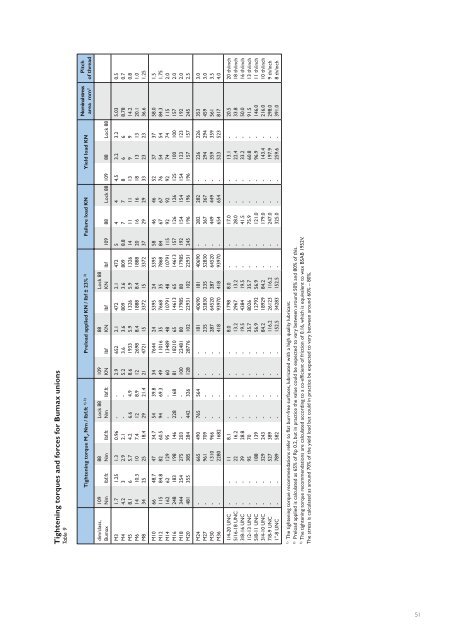

Tightening torques and forces for Bumax unions<br />

Table 9<br />

Pitch<br />

of thread<br />

Nominal stress<br />

area mm2 Tightening torque M v , Nm / Ibf.ft 1), 3) Preload applied KN / Ibf ± 23% 2) Failure load KN Yield load KN<br />

Lock 88<br />

KN Ibf 109 88 Lock 88 109 88 Lock 88<br />

88<br />

KN Ibf<br />

109<br />

KN Ibf<br />

Lock 88<br />

Nm Ibf.ft<br />

88<br />

Nm Ibf.ft<br />

109<br />

Nm Ibf.ft<br />

dim/class,<br />

Bumax<br />

0.5<br />

0.7<br />

0.8<br />

1.0<br />

1.25<br />

5.03<br />

8.78<br />

14.2<br />

20.1<br />

36.6<br />

3.2<br />

6<br />

9<br />

13<br />

23<br />

3.2<br />

6<br />

9<br />

13<br />

23<br />

4.5<br />

8<br />

13<br />

18<br />

33<br />

4<br />

7<br />

11<br />

16<br />

29<br />

4<br />

7<br />

11<br />

16<br />

29<br />

5<br />

8.8<br />

14<br />

20<br />

37<br />

472<br />

809<br />

1326<br />

1888<br />

3372<br />

2.1<br />

3.6<br />

5.9<br />

8.4<br />

15<br />

472<br />

809<br />

1326<br />

1888<br />

3372<br />

2.1<br />

3.6<br />

5.9<br />

8.4<br />

15<br />

652<br />

3.6<br />

1933<br />

2698<br />

4721<br />

2.9<br />

5.2<br />

8.6<br />

12<br />

21<br />

-<br />

-<br />

4.9<br />

8.9<br />

21.4<br />

-<br />

-<br />

6.6<br />

12<br />

29<br />

0.96<br />

2.1<br />

4.2<br />

7.4<br />

18.4<br />

1.3<br />

2.9<br />

5.7<br />

10<br />

25<br />

1.25<br />

3<br />

6<br />

10.3<br />

25<br />

1.7<br />

4.2<br />

8.1<br />

14<br />

34<br />

M3<br />

M4<br />

M5<br />

M6<br />

M8<br />

1.5<br />

1.75<br />

2.0<br />

2.0<br />

2.0<br />

2.5<br />

58.0<br />

84.3<br />

115<br />

157<br />

192<br />

245<br />

37<br />

54<br />

74<br />

100<br />

123<br />

157<br />

37<br />

54<br />

74<br />

100<br />

123<br />

157<br />

52<br />

76<br />

92<br />

125<br />

154<br />

196<br />

46<br />

67<br />

92<br />

126<br />

154<br />

196<br />

46<br />

67<br />

92<br />

126<br />

154<br />

196<br />

58<br />

84<br />

115<br />

157<br />

192<br />

245<br />

5395<br />

7868<br />

10791<br />

14613<br />

17985<br />

22931<br />

24<br />

35<br />

48<br />

65<br />

80<br />

102<br />

5395<br />

7668<br />

10791<br />

14613<br />

17985<br />

22931<br />

24<br />

35<br />

48<br />

65<br />

80<br />

102<br />

7644<br />

11016<br />

13489<br />

18210<br />

22481<br />

28776<br />

34<br />

49<br />

60<br />

81<br />

100<br />

128<br />

39.8<br />

69.3<br />

-<br />

168<br />

-<br />

326<br />

54<br />

94<br />

-<br />

228<br />

-<br />

442<br />

34.7<br />

60.5<br />

95<br />

146<br />

203<br />

284<br />

47<br />

82<br />

129<br />

198<br />

275<br />

385<br />

48.7<br />

84.8<br />

62<br />

183<br />

254<br />

355<br />

66<br />

115<br />

162<br />

248<br />

344<br />

481<br />

M10<br />

M12<br />

M14<br />

M16<br />

M18<br />

M20<br />

3.0<br />

3.0<br />

3.5<br />

4.0<br />

20 th/inch<br />

18 th/inch<br />

16 th/inch<br />

13 th/inch<br />

11 th/inch<br />

10 th/inch<br />

9 th/inch<br />

8 th/inch<br />

353<br />

459<br />

561<br />

817<br />

226<br />

294<br />

359<br />

523<br />

226<br />

294<br />

359<br />

523<br />

-<br />

-<br />

-<br />

-<br />

282<br />

367<br />

449<br />

654<br />

282<br />

367<br />

449<br />

654<br />

-<br />

-<br />

-<br />

-<br />

40690<br />

52830<br />

64520<br />

93970<br />

181<br />

235<br />

287<br />

418<br />

40690<br />

52830<br />

64520<br />

93970<br />

181<br />

235<br />

287<br />

418<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

564<br />

-<br />

-<br />

-<br />

765<br />

-<br />

-<br />

-<br />

490<br />

709<br />

966<br />

1682<br />

665<br />

961<br />

1310<br />

2280<br />

-<br />

-<br />

-<br />

-<br />

20.5<br />

33.8<br />

50.0<br />

91.5<br />

146.0<br />

216.0<br />

298.0<br />

391.0<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

13.1<br />

22.4<br />

33.2<br />

60.8<br />

96.9<br />

143.4<br />

197.9<br />

259.6<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

17.0<br />

28.0<br />

41.5<br />

75.9<br />

121.0<br />

179.0<br />

247.0<br />

325.0<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

8.0<br />

13.2<br />

19.5<br />

35.7<br />

56.9<br />

84.2<br />

116.2<br />

152.5<br />

1798<br />

2967<br />

4384<br />

8026<br />

12792<br />

18929<br />

26123<br />

34283<br />

8.0<br />

13.2<br />

19.5<br />

35.7<br />

56.9<br />

84.2<br />

116.2<br />

152.5<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

8.1<br />

16.2<br />

28.8<br />

70<br />

139<br />

243<br />

389<br />

582<br />

11<br />

22<br />

39<br />

95<br />

188<br />

329<br />

527<br />

789<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

M24<br />

M27<br />

M30<br />

M36<br />

1/4-20 UNC<br />

5/16-18 UNC<br />

3/8-16 UNC<br />

1/2-13 UNC<br />

5/8-11 UNC<br />

3/4-10 UNC<br />

7/8-9 UNC<br />

1"-8 UNC<br />

1) The tightening torque recommendations refer to fl at burr-free surfaces, lubricated with a high quality lubricant.<br />

2) Preload applied is calculated as 65% of Rp 0.2, but in practice the value could be expected to vary between around 50% and 80% of this.<br />

3) The tightening torque recommendations are calculated according to a co-effi cient of friction of 0.16, which is equivalent to wax BSAB 1952V.<br />

The stress is calculated as around 70% of the yield load but could in practice be expected to vary between around 60% – 80%.<br />

51