HDG Magazine Issue 1 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HOT DIP GALVANIZING<br />

01 | <strong>2018</strong><br />

2<br />

use of prefabrication and barged delivery to site<br />

strengthening of the existing Victorian masonry viaduct and station<br />

roof<br />

use of overwater ground investigation to inform the pier design<br />

tailored working methods in and around the three operational railway<br />

lines<br />

FE analysis of the soil structure interaction for the pile design<br />

use of bespoke lifting equipment.<br />

Technical excellence<br />

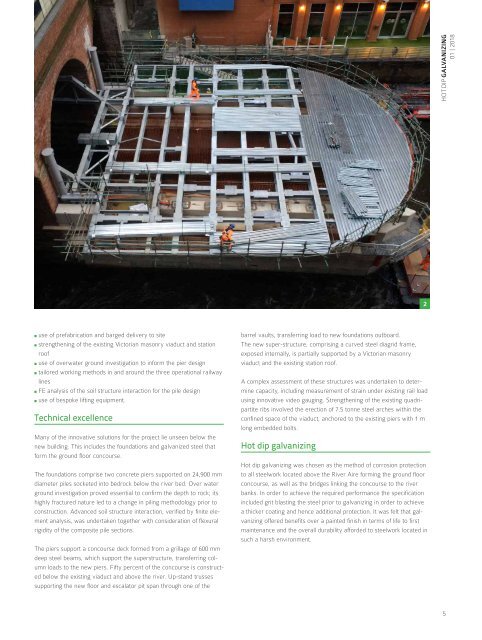

Many of the innovative solutions for the project lie unseen below the<br />

new building. This includes the foundations and galvanized steel that<br />

form the ground floor concourse.<br />

The foundations comprise two concrete piers supported on 24,900 mm<br />

diameter piles socketed into bedrock below the river bed. Over water<br />

ground investigation proved essential to confirm the depth to rock; its<br />

highly fractured nature led to a change in piling methodology prior to<br />

construction. Advanced soil structure interaction, verified by finite element<br />

analysis, was undertaken together with consideration of flexural<br />

rigidity of the composite pile sections.<br />

The piers support a concourse deck formed from a grillage of 600 mm<br />

deep steel beams, which support the superstructure, transferring column<br />

loads to the new piers. Fifty percent of the concourse is constructed<br />

below the existing viaduct and above the river. Up-stand trusses<br />

supporting the new floor and escalator pit span through one of the<br />

barrel vaults, transferring load to new foundations outboard.<br />

The new super-structure, comprising a curved steel diagrid frame,<br />

exposed internally, is partially supported by a Victorian masonry<br />

viaduct and the existing station roof.<br />

A complex assessment of these structures was undertaken to determine<br />

capacity, including measurement of strain under existing rail load<br />

using innovative video gauging. Strengthening of the existing quadripartite<br />

ribs involved the erection of 7.5 tonne steel arches within the<br />

confined space of the viaduct, anchored to the existing piers with 1 m<br />

long embedded bolts.<br />

Hot dip galvanizing<br />

Hot dip galvanizing was chosen as the method of corrosion protection<br />

to all steelwork located above the River Aire forming the ground floor<br />

concourse, as well as the bridges linking the concourse to the river<br />

banks. In order to achieve the required performance the specification<br />

included grit blasting the steel prior to galvanizing in order to achieve<br />

a thicker coating and hence additional protection. It was felt that galvanizing<br />

offered benefits over a painted finish in terms of life to first<br />

maintenance and the overall durability afforded to steelwork located in<br />

such a harsh environment.<br />

5