What is Corrugated Stainless Steel Tubing

Corrugated Stainless Steel Tubing (CSST) is a flexible, stainless steel pipe used to supply natural gas and propane in residential, commercial and industrial structures.

Corrugated Stainless Steel Tubing (CSST) is a flexible, stainless steel pipe used to supply natural gas and propane in residential, commercial and industrial structures.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

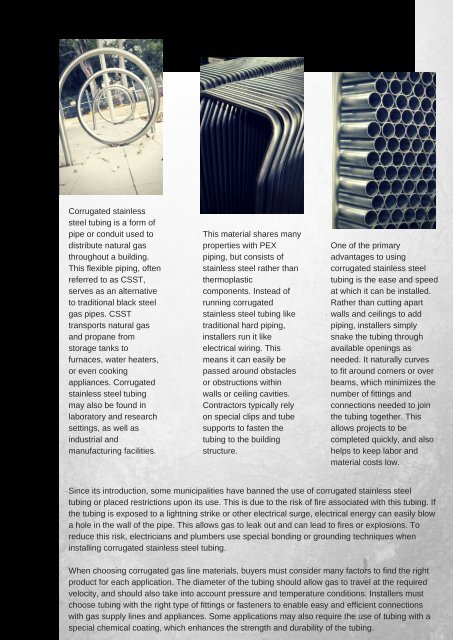

<strong>Corrugated</strong> stainless<br />

steel tubing <strong>is</strong> a form of<br />

pipe or conduit used to<br />

d<strong>is</strong>tribute natural gas<br />

throughout a building.<br />

Th<strong>is</strong> flexible piping, often<br />

referred to as CSST,<br />

serves as an alternative<br />

to traditional black steel<br />

gas pipes. CSST<br />

transports natural gas<br />

and propane from<br />

storage tanks to<br />

furnaces, water heaters,<br />

or even cooking<br />

appliances. <strong>Corrugated</strong><br />

stainless steel tubing<br />

may also be found in<br />

laboratory and research<br />

settings, as well as<br />

industrial and<br />

manufacturing facilities.<br />

Th<strong>is</strong> material shares many<br />

properties with PEX<br />

piping, but cons<strong>is</strong>ts of<br />

stainless steel rather than<br />

thermoplastic<br />

components. Instead of<br />

running corrugated<br />

stainless steel tubing like<br />

traditional hard piping,<br />

installers run it like<br />

electrical wiring. Th<strong>is</strong><br />

means it can easily be<br />

passed around obstacles<br />

or obstructions within<br />

walls or ceiling cavities.<br />

Contractors typically rely<br />

on special clips and tube<br />

supports to fasten the<br />

tubing to the building<br />

structure.<br />

One of the primary<br />

advantages to using<br />

corrugated stainless steel<br />

tubing <strong>is</strong> the ease and speed<br />

at which it can be installed.<br />

Rather than cutting apart<br />

walls and ceilings to add<br />

piping, installers simply<br />

snake the tubing through<br />

available openings as<br />

needed. It naturally curves<br />

to fit around corners or over<br />

beams, which minimizes the<br />

number of fittings and<br />

connections needed to join<br />

the tubing together. Th<strong>is</strong><br />

allows projects to be<br />

completed quickly, and also<br />

helps to keep labor and<br />

material costs low.<br />

Since its introduction, some municipalities have banned the use of corrugated stainless steel<br />

tubing or placed restrictions upon its use. Th<strong>is</strong> <strong>is</strong> due to the r<strong>is</strong>k of fire associated with th<strong>is</strong> tubing. If<br />

the tubing <strong>is</strong> exposed to a lightning strike or other electrical surge, electrical energy can easily blow<br />

a hole in the wall of the pipe. Th<strong>is</strong> allows gas to leak out and can lead to fires or explosions. To<br />

reduce th<strong>is</strong> r<strong>is</strong>k, electricians and plumbers use special bonding or grounding techniques when<br />

installing corrugated stainless steel tubing.<br />

When choosing corrugated gas line materials, buyers must consider many factors to find the right<br />

product for each application. The diameter of the tubing should allow gas to travel at the required<br />

velocity, and should also take into account pressure and temperature conditions. Installers must<br />

choose tubing with the right type of fittings or fasteners to enable easy and efficient connections<br />

with gas supply lines and appliances. Some applications may also require the use of tubing with a<br />

special chemical coating, which enhances the strength and durability of the tubing.