Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

In such a plant, the drying cycles<br />

are extended with 24 to 45 hours<br />

being quite common in certain<br />

cases. This is a direct result of<br />

the low evaporative rate which<br />

normally is in the region of<br />

0.15 to 0.25 lb/ft2hr.<br />

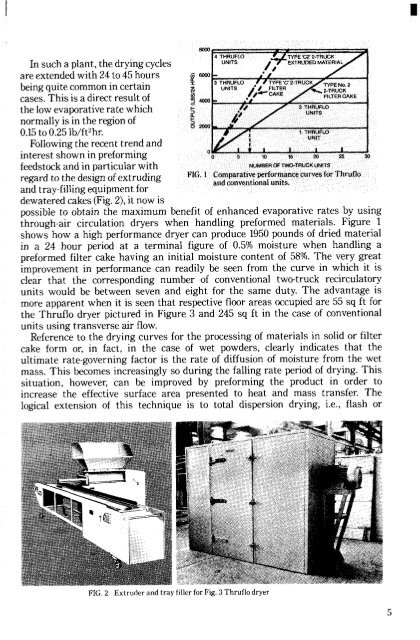

Following the recent trend and<br />

interest shown in preforming<br />

feedstock and in particular with<br />

regard to the design of extruding<br />

and tray-filling equipment for<br />

dewatered cakes (Fig. 2), it now is<br />

possible to obtain the maximum benefit of enhanced evaporative rates by using<br />

through-air circulation dryers when handling preformed materials. Figure 1<br />

shows how a high performance dryer can produce 1950 pounds of dried material<br />

in a 24 hour period at a terminal figure of 0.5% moisture when handling a<br />

preformed filter cake having an initial moisture content of 58%. The very great<br />

improvement in performance can readily be seen from the curve in which it is<br />

clear that the corresponding number of conventional two-truck recirculatory<br />

units would be between seven and eight for the same duty. The advantage is<br />

more apparent when it is seen that respective floor areas occupied are 55 sq ft for<br />

the Thruflo dryer pictured in Figure 3 and 245 sq ft in the case of conventional<br />

units using transverse air flow.<br />

Reference to the drying curves for the processing of materials in solid or filter<br />

cake form or, in fact, in the case of wet powders, clearly indicates that the<br />

ultimate rate-governing factor is the rate of diffusion of moisture from the wet<br />

mass. This becomes increasingly so during the falling rate period of drying. This<br />

situation, however, can be improved by preforming the product in order to<br />

increase the effective surface area presented to heat and mass transfer. The<br />

logical extension of this technique is to total dispersion drying, i.e., flash or<br />

FIG. 2 Extruder and tray filler for Fig. 3 Thruflo dryer<br />

5