Solenoid ON/OFF Control Valve E5250-10

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SOLENOID <strong>ON</strong>/<strong>OFF</strong><br />

C<strong>ON</strong>TROL VALVE, <strong>E5250</strong>-<strong>10</strong><br />

Envotec Model <strong>E5250</strong>-<strong>10</strong> Pilot Operated <strong>Solenoid</strong> control<br />

valves are <strong>ON</strong>/<strong>OFF</strong> type designed to open or close with<br />

receiving an electrical signal to the 3-way solenoid pilot control.<br />

The signal to the solenoid to open or close can also achieved<br />

by flow switches, float switches, level sensing electrodes,<br />

pressure switches, timers and other similar electrical signals.<br />

The 3-way solenoid pilot provisioned with manual override<br />

knob, in the event of power failure the knob can be turned to<br />

function the valve in a manual mode. Turning the knob back to<br />

original position activates the valve to auto mode.<br />

The valve can be configured to normally open or normally<br />

closed based on user requirements.<br />

FEATURES<br />

• High hydrodynamic section globe body, w/o stagnation<br />

pockets<br />

• NSF Approved epoxy coating internal/external suits<br />

potable(drinking) water applications<br />

• Simple structure, easy installation/disassembly<br />

• Head loss and cavitation risks reduction<br />

• Excellent corrosion strength<br />

• Conformity with both European and American standards<br />

• <strong>Valve</strong> equipped with pilot strainer to protect foreign debris<br />

entering to the pilot system<br />

• <strong>Valve</strong> equipped with isolation cocks for easy maintenance<br />

• Maintenance and repairs is possible without removing the<br />

main valve body from the line.<br />

• <strong>Valve</strong> equipped with pressure gauge for physical<br />

visualization of inlet/outlet pressure<br />

• Main-valve body provisioned with drain plug for flushing out<br />

dirt during the preliminary installation and when required.<br />

• <strong>Valve</strong> equipped with position indicator for physical<br />

visualization of valve open/close position<br />

TECHNICAL SPECIFICATI<strong>ON</strong>S<br />

Max. Working Pressure: 16 bar (232 psi)<br />

Max. Working Temperature: 80ºC (176°F)<br />

Nominal Diameter: DN32~ DN600<br />

Fluid Medium: Water<br />

<strong>Solenoid</strong> Coil Voltage: 24, 240VAC, 50Hz / 24, 240VDC<br />

(Other voltages are available on request).<br />

APPLICATI<strong>ON</strong>S<br />

• Water supply, distribution & pump stations<br />

• Water treatment<br />

• Water supply stations (airports, marine and fluvial ports)<br />

• Sports complexes, Swimming pools, Aquariums, Amusement<br />

parks<br />

• Suitable for Residential, Commercial, Industrial, Irrigation,<br />

Fire protection & similar installations<br />

3<br />

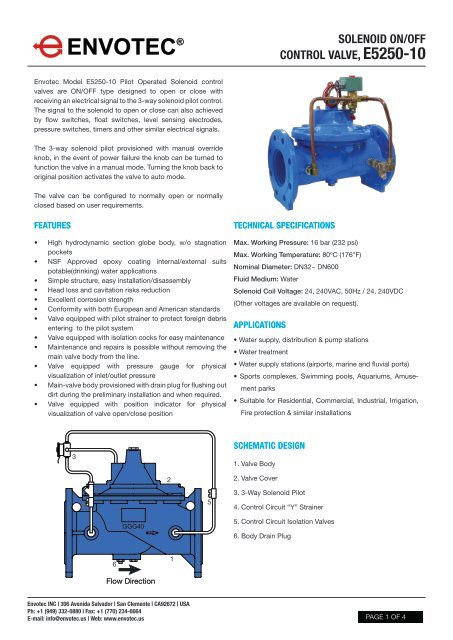

SCHEMATIC DESIGN<br />

1. <strong>Valve</strong> Body<br />

5<br />

4<br />

2<br />

5<br />

2. <strong>Valve</strong> Cover<br />

3. 3-Way <strong>Solenoid</strong> Pilot<br />

4. <strong>Control</strong> Circuit “Y” Strainer<br />

GGG40<br />

5. <strong>Control</strong> Circuit Isolation <strong>Valve</strong>s<br />

6. Body Drain Plug<br />

6<br />

1<br />

Flow Direction<br />

Envotec INC | 306 Avenida Salvador | San Clemente | CA92672 | USA<br />

Ph: +1 (949) 332-0880 | Fax: +1 (770) 234-6664<br />

E-mail: info@envotec.us | Web: www.envotec.us PAGE 1 OF 4

MAIN VALVE, E5000 PILOT, E53-<strong>10</strong><br />

Body & Cover: Ductile Iron ASTM A536<br />

Coating: Fusion Bonded Epoxy Coating to 300 Microns<br />

Seat/Stem/Spring: Stainless Steel 316<br />

Diaphragm/Disc/O-ring: EPDM<br />

Diaphragm Washer: Stainless Steel 316<br />

Disc Retainer/Guide: Stainless Steel 316<br />

Cover Bearing: Stainless Steel 316<br />

Cover Bolts/Seat Screws: Stainless Steel 316<br />

Body/Cover Plugs: Stainless Steel 316<br />

STANDARD PILOT SYSTEM<br />

Ball <strong>Valve</strong> (Isolation Cocks): Brass , EBV-BR<strong>10</strong>0<br />

Y-Strainer: Bronze ASTM B62, ES-BZ<strong>10</strong>0<br />

Body: Brass<br />

Seals & Disc: NBR<br />

Core Tube: 305 Stainless Steel<br />

Core & Plug Nut: 430F Stainless Steel<br />

Core Springs: 302 Stainless Steel<br />

Shading Coil: Copper<br />

Disc-Holder: CA<br />

Core Guide: CA (<strong>10</strong>.1 and 17.1 Watt only)<br />

PILOT CIRCUIT<br />

Tubing: Copper<br />

Tube Fittings: Brass<br />

OTHER C<strong>ON</strong>FIGURATI<strong>ON</strong>S<br />

<strong>E5250</strong>-11 Booster Pump <strong>Control</strong> <strong>Valve</strong><br />

<strong>E5250</strong>-12 Booster Pump <strong>Control</strong> <strong>Valve</strong> with Mechanical Lift Check<br />

WEIGHT & DIMENSI<strong>ON</strong>S<br />

ØD L H B<br />

WEIGHT<br />

(Kgs)<br />

32 180 220 165 17<br />

40 180 220 165 17<br />

50 230 220 165 17<br />

65 290 230 185 20<br />

80 3<strong>10</strong> 290 200 26<br />

<strong>10</strong>0 350 3<strong>10</strong> 235 35<br />

125 400 340 270 48<br />

150 480 440 300 85<br />

200 600 535 360 115<br />

250 730 560 425 140<br />

300 850 660 485 420<br />

350 980 695 555 530<br />

400 1<strong>10</strong>0 985 620 800<br />

500 1250 <strong>10</strong>40 730 950<br />

600 1450 <strong>10</strong>95 845 1350<br />

700 1650 1305 9<strong>10</strong> 2600<br />

800 1850 1360 <strong>10</strong>25 3000<br />

All dimensions in: mm<br />

Envotec INC | 306 Avenida Salvador | San Clemente | CA92672 | USA<br />

Ph: +1 (949) 332-0880 | Fax: +1 (770) 234-6664<br />

E-mail: info@envotec.us | Web: www.envotec.us PAGE 2 OF 4

CAVITATI<strong>ON</strong> CURVE<br />

Too high pressure loss and too low downstream pressure<br />

may cause valve deterioration. To determine if<br />

cavitation is due to pressure conditions, it is necessary<br />

to refer to cavitation curve. Just in case reduce ∆p by<br />

installing more cascade flow control valves will help<br />

valve to work outside cavitation zone.<br />

A. Cavitation free zone<br />

B. Cavitation zone<br />

Kv FACTOR<br />

Kv factor values expressed in m3/h are intended for fully open valve and refer to flow rate which passing through the valve, causes<br />

a pressure loss equal to 1 bar.<br />

DN 50 65 80 <strong>10</strong>0 125 150 200 250 300 350 400 500 600 700 800<br />

Kv(m3/h) 50 52 1<strong>10</strong> 136 198 288 490 7<strong>10</strong> 1390 1530 2280 3220 3920 7200 7400<br />

Note: It is recommended to install by a experienced/ trained product installer. You are required to thoroughly read all installation instructions<br />

and product safety information before beginning the installation of this product. Local plumbing codes shall govern installation requirements.<br />

Ensure that all applicable national, local building codes and safety rules are observed throughout the installation.<br />

Envotec INC | 306 Avenida Salvador | San Clemente | CA92672 | USA<br />

Ph: +1 (949) 332-0880 | Fax: +1 (770) 234-6664<br />

E-mail: info@envotec.us | Web: www.envotec.us PAGE 3 OF 4

INSTALLATI<strong>ON</strong> REQUIREMENTS<br />

Recommended to install valves in horizontal position.<br />

Avoid installing valves 6" and above in a vertical discharge position.<br />

If your installation requires vertical position, consult factory or specify at the time of order.<br />

MAINTENANCE REQUIREMENTS<br />

An Isolation valve (Gate valve/Butterfly valve/Ball valve) should be installed before and after the automatic<br />

control valve for easy maintenance without draining the piping system.<br />

SIZING REQUIREMENTS<br />

Following are the different stage of automatic control valve installations considering minimum flow, maximum flow & pressure<br />

drop across the valve (cavitation) ∆p (P1-P2).<br />

TYPICAL SOLENOID VALVE STATI<strong>ON</strong><br />

Level Sensing <strong>Control</strong>ler<br />

Float Switches<br />

Pressure Switch<br />

Flow Switch<br />

Timers<br />

PLC<br />

BMS/SCADA<br />

GGG40<br />

Flow Direction<br />

Envotec® reserves the right to change or modify product design, construction, specifications or materials without prior notice and without<br />

incurring any obligation to make such changes and modifications on Envotec products previously or subsequently sold.<br />

Envotec INC | 306 Avenida Salvador | San Clemente | CA92672 | USA<br />

Ph: +1 (949) 332-0880 | Fax: +1 (770) 234-6664<br />

E-mail: info@envotec.us | Web: www.envotec.us PAGE 4 OF 4