KVMRT UG ebOOKLET 2019

KVMRT UG ebOOKLET 2019

KVMRT UG ebOOKLET 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

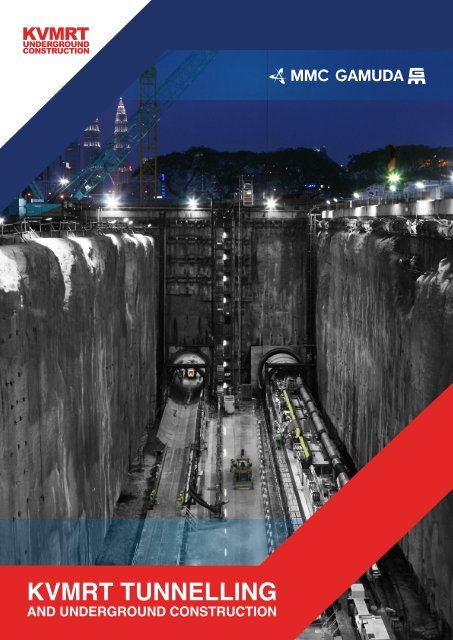

<strong>KVMRT</strong> TUNNELLING<br />

AND UNDERGROUND CONSTRUCTION

ABOUT MMC GAMUDA<br />

MMC Gamuda Joint Venture (JV) is a 50:50 joint venture<br />

between two of Malaysia’s most illustrious<br />

engineering and construction groups –<br />

MMC Corporation Berhad and Gamuda Berhad.<br />

With a combined expertise of two of Malaysia’s largest<br />

infrastructure groups with diverse experience ranging<br />

from urban rail, highways, airports, and bridges to<br />

power generation, water treatment, multi-purpose<br />

ports and sustainable township development, the JV<br />

partnership of MMC Gamuda brings together the best<br />

of Malaysian engineering like no other.<br />

Backed by a sterling track record in developing largescale<br />

projects on time, coupled with its expanding<br />

capability in engineering innovation and breakthrough<br />

solutions, MMC Gamuda is a frontrunner in the<br />

implementation of Malaysia’s new chapter in public<br />

transportation infrastructure – the Klang Valley Mass<br />

Rapid Transit (Sungai Buloh-Kajang Line) as well as<br />

(Sungai Buloh-Serdang-Putrajaya Line) and the<br />

Electrified Double Track Project (Ipoh-Padang Besar).<br />

Armed with comprehensive in-house expertise in<br />

project management skills, tunnelling, geotechnics,<br />

engineering and construction know-how, we are<br />

in the main league of construction players that is<br />

changing the infrastructure built in times to come.<br />

MMC Gamuda developed the world’s first dualpurpose<br />

tunnel designed to alleviate stormwater<br />

flooding and traffic congestion in the heart of Kuala<br />

Lumpur, known as the Stormwater Management and<br />

Road Tunnel (SMART).<br />

With a stormwater diversion channel and doubledeck<br />

motorway merged into a single tunnel, SMART<br />

is a legacy of Malaysian infrastructure development<br />

capability that stormed the world with its unique<br />

concept targeted at solving two of urban cities’ most<br />

critical dilemmas.<br />

Cochrane Station: The VD TBM being assembled in the shaft<br />

1

MMC GAMUDA <strong>KVMRT</strong> (T) SDN BHD<br />

MMC Gamuda <strong>KVMRT</strong> (T) Sdn Bhd (MGKT) was set<br />

up on 30 March 2012 to undertake the design and<br />

construction work for the underground package of<br />

Klang Valley Mass Rapid Transit (<strong>KVMRT</strong>) project. The<br />

<strong>KVMRT</strong> project is part of the Government’s Economic<br />

Transformation Programme and owned by the<br />

Government of Malaysia through MRT Corporation<br />

Sdn Bhd (MRT Corp).<br />

MGKT was awarded the RM8.2billion tunnelling<br />

package for <strong>KVMRT</strong> SBK Line which involves the<br />

design and construction of 9.5km underground<br />

tunnel with seven underground stations. MGKT<br />

won the contract through a competitive bid. The<br />

underground tunnelling alignment runs from the<br />

Semantan North Portal near the Federal Hill past<br />

the urban transport hub of KL Sentral and the busy<br />

streets of Bukit Bintang and Chinatown to the Maluri<br />

South Portal near Taman Miharja.<br />

With proven track record in carrying out tunnelling<br />

and other underground works in the challenging<br />

geology of the Klang Valley, MGKT has also won the<br />

single-largest Mass Rapid Transit (MRT) package to<br />

date worth RM15.47bil for the underground works in<br />

the recently launched MRT Sungai Buloh-Serdang-<br />

Putrajaya (SSP) Line.<br />

The underground works package involves the design,<br />

construction and completion of tunnels, underground<br />

stations and associated structures such as portals and<br />

escape shafts for the SSP Line underground alignment<br />

from the Jalan Ipoh north escape shaft to the Desa<br />

Waterpark south portal.<br />

The line will serve a corridor with a population of<br />

around 3 million people stretching from Sungai Buloh<br />

to Putrajaya and will include Sri Damansara, Kepong,<br />

Batu, Jalan Sultan Azlan Shah, Jalan Tun Razak, KLCC,<br />

Tun Razak Exchange, Kuchai Lama, Seri Kembangan<br />

and Cyberjaya.<br />

The SSP alignment is 52.2km of which 13.5km is<br />

underground. A total of 36 stations, 11 of them<br />

underground, will be built. At commencement of full<br />

service in the second quarter of 2022, the SSP Line is<br />

expected to have a ridership of 529,000 passengers<br />

per day. This is expected to further improve the cronic<br />

traffic congestion currently faced by Kuala Lumpur.<br />

Our Human Capital is our Wealth<br />

2

Proud to be Malaysians, Honoured to be with the Nation’s Landmark Project<br />

ABOUT <strong>KVMRT</strong> PROJECT<br />

ABOUT <strong>KVMRT</strong> PROJECT<br />

Klang Valley Mass Rapid Transit (<strong>KVMRT</strong>) Project is<br />

a rail-based public transport network, envisaged to<br />

radically improve and transform Kuala Lumpur’s public<br />

transportation coverage and to propel the Greater Kuala<br />

Lumpur into one of the top most liveable cities in the<br />

world.<br />

The MRT project which was approved by the Malaysian<br />

Government in December 2010 and launched on 8 July<br />

2011, will help ease traffic congestion and increase the<br />

public transport modal share from 18 % in 2009 to 40 %<br />

in 2020.<br />

It will be the backbone of the new sustainable transport<br />

system, integrating with LRT, Monorail, KTMB Komuter,<br />

intra-city and inter-city bus routes. The MRT project<br />

was made an Entry Point Project of the Economic<br />

Transformation Programme (ETP) under the Greater<br />

Kuala Lumpur/Klang Valley National Key Economic Area<br />

(NKEA).<br />

The ETP is being implemented by the Performance<br />

Management and Delivery Unit (Pemandu) of the Prime<br />

Minister’s Department.<br />

The first MRT line stretches from Sungai Buloh to Kajang<br />

(SBK) and will serve a catchment of 1.2 million residents<br />

travelling between populated residential, commercial<br />

centres and key employment areas in the Klang Valley.<br />

The Sungai Buloh-Kajang line covers a distance of 51km<br />

and hosts 31 stations.<br />

3<br />

The RM8.2billion tunnelling package for <strong>KVMRT</strong> SBK<br />

Line involves the design and construction of 9.5km<br />

underground tunnel with seven underground stations.<br />

MGKT won the contract through a competitive bid.<br />

The underground tunnelling alignment runs from the<br />

Semantan North Portal near the Federal Hill past the<br />

urban transport hub of KL Sentral and the busy streets of<br />

Bukit Bintang and Chinatown to the Maluri South Portal<br />

near Taman Miharja.<br />

The entire 51km MRT SBK Line is expected to be fully<br />

operational by mid-2017.<br />

The second MRT Line, the Sungai Buloh-Serdang-<br />

Putrajaya (SSP) Line will serve a corridor with a<br />

population of around 3 million people stretching<br />

from Sungai Buloh to Putrajaya and will include Sri<br />

Damansara, Kepong, Batu, Jalan Sultan Azlan Shah, Jalan<br />

Tun Razak, KLCC, Tun Razak Exchange, Kuchai Lama, Seri<br />

Kembangan and Cyberjaya.<br />

The 52.2km alignment, including13.5 km is underground<br />

will have a total of 36 stations, 11 of which will be built<br />

underground.<br />

At commencement of full service in the second quarter<br />

of 2022, the SSP Line is expected to have a ridership of<br />

529,000 passengers per day.<br />

A third line called the Circle Line is still at the planning<br />

stage.

<strong>KVMRT</strong><br />

SBK Line<br />

8 July 2011:<br />

MRT project was officially<br />

launched.<br />

30 May 2013:<br />

The launch of the first<br />

Variable Density Tunnel<br />

Boring Machine (VD TBM).<br />

SBK Line<br />

SBK Line<br />

15 December 2016:<br />

Phase One of the MRT<br />

SBK Line was officially<br />

launched.<br />

17 July 2017:<br />

Phase Two of the MRT<br />

SBK Line was officially<br />

launched.<br />

SBK Line<br />

SSP Line<br />

15 September 2016:<br />

The second MRT Line i.e.<br />

SSP Line was launched .<br />

<strong>KVMRT</strong> FACTS AT A GLANCE<br />

Details SBK Line SSP Line<br />

Total Distance 51 km 52.2 km<br />

Underground Alignment 9.5 km 13.5 km<br />

Stations<br />

31 stations including 7<br />

36 stations including 9<br />

underground<br />

underground + 2 shell and core<br />

Ridership<br />

Completion<br />

Estimated daily ridership of<br />

over 400,000<br />

Phase 1: 16 December 2016<br />

Phase 2: 17 July 2017<br />

Estimated daily ridership<br />

of about 530,000<br />

Second quarter of 2022<br />

4

THE BUILDING METHODS OF<br />

THE UNDERGROUND STATIONS<br />

1<br />

Bottom-up Construction<br />

2 Top-down Construction<br />

Conventionally, buildings with underground basements are built by<br />

bottom-up method where sub-structures and super structure floors<br />

are constructed sequentially from the lowest level of basement to<br />

the top of the super-structure.<br />

To illustrate the conventional bottom-up construction further, a<br />

trench is excavated from the surface where the tunnel is constructed<br />

and then the trench is backfilled and the surface is methodologically<br />

restored afterwards.<br />

The trench could be formed using open cut methods (sides sloped<br />

back and unsupported), or with vertical faces using an excavation<br />

support system. In bottom-up construction, the tunnel is completed<br />

before it is covered up and the surface reinstated.<br />

This method however is not feasible for the large scale projects with<br />

limited construction time through extreme terrain constraints.<br />

The bottom-up construction method also comes with several<br />

benefits. Waterproofing can be applied to the outside surface of the<br />

structure.<br />

Additionally, the interior of the excavation makes it easily accessible<br />

for construction equipment and the delivery, storage and placement<br />

of materials.<br />

Supplementary drainage systems can also be installed outside the<br />

structure to channel water or divert it away from the structure.<br />

Top-down construction method builds the permanent structure<br />

components of the basement along with excavation from the top to<br />

bottom. By employing this method basement floors are constructed<br />

as the excavation progresses.<br />

The top-down method is mainly used for the two types of urban<br />

structures, tall buildings with deep basements or underground<br />

structures for example car parks, underpasses and underground<br />

stations.<br />

The top-down method is ideal for cavernous excavation projects<br />

where soil movements must be minimized. This approach is ideal for<br />

Klang Valley’s extreme geology.<br />

This construction method reduces overall construction time, and<br />

has been adopted by major projects worldwide to minimize lengthy<br />

construction periods.<br />

Typically construction begins with the installation of the retaining<br />

wall, then proceeding with load-bearing elements that will carry the<br />

future super structure, in this case of the Sungai Buloh-Kajang (SBK)<br />

Line underground stations.<br />

Basement columns are constructed before any excavation or load<br />

bearing elements take place.<br />

Tun Razak Exchange Station: Bottom-up construction method<br />

5

TUNNELLING SPECIFICATIONS<br />

Tunnelling Specifications: SBK Line<br />

Tunnelling Specifications: SSP Line<br />

13.5km 12km Dec 2017 - June 2020 6.7m<br />

6

UNDERSTANDING THE GEOLOGY<br />

BENEATH KUALA LUMPUR<br />

The alignment of the SBK Line traverses through two different geological formations which are Karstic Limestone<br />

and Kenny Hill, both of which account for approximately 50% each.<br />

For SSP Line, three different geological profiles are involved which are Kenny Hill, Karstic Limestone and Granite.<br />

Kenny Hill<br />

Karstic Limestone<br />

Granite<br />

Major tunnelling projects around<br />

the world have been successfully<br />

completed through actively<br />

anticipating, monitoring and<br />

predicting ground movement<br />

behaviours, innovative highprecision<br />

engineering, along with<br />

efficient and safe construction<br />

methods.<br />

This geology dominates from the<br />

Northern Portal at Semantan to<br />

Pavilion Shopping Complex. The<br />

Kenny Hill Formation is essentially<br />

sedimentary rock formation.<br />

It consists of a sequence of<br />

interbedded clastic sedimentary<br />

rocks such as sandstones, siltstone<br />

and shale.<br />

Such geology is challenging<br />

during tunnelling works as there<br />

is a mixture of extreme hard<br />

rock (skarn), loose silty sand and<br />

gravels due to alluvial deposits.<br />

The loose silty sands and gravels<br />

can be particularly difficult to deal<br />

with as they can contain high<br />

volumes of groundwater and act<br />

as a waterway once broken into.<br />

The fissure water can cause<br />

decompaction and ground<br />

pressure water inrush can be<br />

released that could lead to<br />

ground subsidence disrupting the<br />

ground surface causing harm to<br />

the general public.<br />

This geology dominates the area<br />

just outside the Pavilion Shopping<br />

Complex at Bukit Bintang to the<br />

Southern Portal Maluri at Cheras.<br />

The Kuala Lumpur Limestone<br />

formation is one of the most<br />

challenging formations due to its<br />

complexity.<br />

The water erosion left below the<br />

surface, cliffs, pinnacles, cavities and<br />

interconnected pathways known as<br />

solution features.<br />

The solution features can hold<br />

water and cavities are overlain<br />

by loose alluvium and any<br />

change in pressure can result in<br />

collapse. With such unpredictable<br />

geological conditions, it is vital to<br />

control ground loss and pressure<br />

fluctuations in the midst of<br />

tunnelling works to avoid sinkholes,<br />

reduce settlement and limit the<br />

impact on existing structures.<br />

Due to its riddled underground<br />

passages, some cavities may be<br />

filled with water. Karst sinkholes<br />

and ground subsidence occur when<br />

disturbances to these underground<br />

water tables cause earth and other<br />

debris to shift, disrupting the<br />

equilibrium of the system.<br />

Another possible consequence<br />

is eruptions of mud to the road<br />

surface when the tunnelling slurry<br />

finds its way to the surface during<br />

the boring process.<br />

The Granite rock is geologically<br />

younger than the Kuala Lumpur<br />

Limestone and the Kenny Hill<br />

formation. It intrudes both the<br />

Limestone and the Kenny Hill<br />

formation. The rock is exposed in<br />

various localities in city, such as in the<br />

Bukit Lanjan area (NKVE), the Mont<br />

Kiara & Sri Hartamas area, the Sri<br />

Damansara area, Damansara Perdana<br />

and Taman Tun Dr. Ismail.<br />

Granite is often weathered to various<br />

weathering grades. Wherever granite<br />

is encountered along the tunnel<br />

alignment or at the underground<br />

stations, the bedrock is inevitably<br />

covered with a residual soil mantle of<br />

varying thickness (tens of metres).<br />

Tunnelling through good quality,<br />

massive granite rock using TBM would<br />

be a straight forward, non-problematic<br />

effort except for the tear and wear of<br />

the cutting tools resulting in more<br />

frequent interventions to be carried<br />

out. However, due to the different<br />

grades of weathering of the granite,<br />

mixed face of rock and residual soils<br />

can be encountered and this can cause<br />

some difficulties.<br />

Tunnel face conditions can thus vary<br />

from full face rock, mixed face rocksoil,<br />

or full face soil. Stability of tunnel<br />

face/roof can also be affected by the<br />

orientations of the various major joints/<br />

joint sets in the granite with respect to<br />

the direction of tunnelling and adverse<br />

water conditions of rock/soil interface.<br />

7

GEOLOGICAL VIEW<br />

SBK Line<br />

SSP Line<br />

8

WORLD’S FIRST VARIABLE DENSITY SLURRY<br />

TUNNEL BORING MACHINE (VD TBM)<br />

The VD TBM is the most technologically<br />

advanced TBM in the world. It works<br />

on the principle where the density of<br />

the fresh bentonite pumped into the<br />

excavation chamber can be varied<br />

/ increased according to the ground<br />

condition, hence reducing the incidence<br />

of sinkhole, subsidence and settlement.<br />

This technological marvel has been<br />

hailed as a breakthrough by industry<br />

thought-leaders<br />

9

VARIABLE DENSITY SLURRY TUNNEL<br />

BORING MACHINE (VD TBM)<br />

With almost half of the tunnel alignment sitting in<br />

the Grade V Karstic Limestone, MMC Gamuda had<br />

proposed for this section a twin mode tunnel boring<br />

The Variable Density Slurry TBM uses higher density slurry<br />

with increased viscosity to prevent the loss of ground surface.<br />

By preventing the loss of slurry into cavities, and from<br />

-<br />

venting sinkholes that can disrupt the surface ground of<br />

the Cityscape.<br />

machine (TBM) that would operate in both ‘slurry’ and<br />

‘EPB’ modes, additionally equipped with facility to use<br />

a higher density slurry.<br />

This innovative technology was co-developed by MMC<br />

Gamuda and Herrenknecht AG. A total of six VD TBMS were<br />

used to bore the <strong>KVMRT</strong> tunnels.<br />

On this <strong>KVMRT</strong> project, six twin-mode TBMs with<br />

variable density provision were used to undertake<br />

7.5km of tunnelling through the limestone for the SBK<br />

Line, which was completed end June 2014. The same<br />

TBMs are refurbished to be used for the SSP Line.<br />

The state-of-the-art Tunnel Boring Machine excavates<br />

rock and soil with special tools while building a<br />

permanent precast concrete lining of the tunnels at<br />

the same time.<br />

The two types of TBMs deployed are:<br />

• Variable Density Slurry (VD TBM)<br />

• Earth Pressure Balance (EPB TBM)<br />

The first of its kind in the world, this specialised<br />

Tunnel Boring Machine was designed in particular<br />

to manage extreme Karstic Limestone geology. Our<br />

breakthrough engineering and high-technology<br />

approach has continuously positioned us as the<br />

leading force in Malaysia’s infrastructure planning<br />

and development, enabling us to set numerous<br />

benchmarks in the construction industry.<br />

Taking innovative engineering to the next level,<br />

we collaborated with the world’s largest tunnel<br />

boring machine manufacturer, Herrenknecht AG,<br />

to develop the world’s first Variable Density Tunnel<br />

Boring Machine (VD TBM).<br />

The VD TBM is a slurry machine designed for several<br />

modes of tunnelling, both in slurry and EPB, with a<br />

facility to vary the density of the slurry. The ‘variable<br />

density’ enhancement that led to this technological<br />

innovation is the first of its kind in the world. It is a<br />

direct result of MMC Gamuda’s previous experience<br />

from the involvement in tunnelling through the<br />

same Karstic Limestone ground conditions in<br />

The Variable<br />

the vicinity<br />

Density<br />

of Kuala<br />

Slurry<br />

Lumpur<br />

TBM uses<br />

MRT<br />

higher<br />

project,<br />

density<br />

albeit<br />

slurry<br />

with<br />

with<br />

increased<br />

a larger<br />

viscosity<br />

diameter<br />

to prevent<br />

single<br />

the<br />

dual<br />

loss<br />

purpose<br />

of ground<br />

tunnel<br />

surface.<br />

designed By preventing to alleviate the loss floods of slurry and into carry cavities, traffic and (SMART from<br />

Project).<br />

-<br />

venting sinkholes that can disrupt the surface ground of<br />

the Cityscape. The VD TBM was declared the winner of the<br />

International Tunnelling and Underground Space<br />

This innovative Awards 2014 technology in London was under co-developed the Technical by MMC<br />

Gamuda Innovation and Herrenknecht of the Year AG. Category A total and of six has VD since TBMS been were<br />

used adopted to bore the in many <strong>KVMRT</strong> tunnelling tunnels. projects worldwide in<br />

different geology.<br />

10

EARTH PRESSURE BALANCE TUNNEL<br />

BORING MACHINE (EPB TBM)<br />

The Earth Pressure Balance TBM is employed to manage the Kenny Hill formation, to meet its inherent<br />

cohesiveness and plasticity.<br />

This TBM uses excavated soil to provide continuous support to the tunnel face by balancing the earth pressure<br />

against the forward pressure of the machine.<br />

Typical Earth Retaining System & Station Construction in Kenny Hill<br />

Traffic is diverted for the construction of the station box, while a diaphragm wall construction is installed as a<br />

temporary & permanent structure. Both strutting and ground anchors are used in the excavation of Kenny Hill.<br />

Slabs and internal station structures are constructed and the ground above the roof is backfilled. Traffic is<br />

reinstated above the station box once construction is completed.<br />

11

SAFE TUNNELLING METHOD<br />

TBMs are safer as a tunnelling<br />

method:<br />

Tunnel Boring Machines have<br />

revolutionised tunnelling methods,<br />

making it possible to create<br />

underground spaces in highly built-up<br />

cities with overwhelming population<br />

density<br />

12

MRT SUNGAI BULOH-KAJANG LINE<br />

(SBK LINE) ALIGNMENT<br />

Malaysia is heralding a new era never before seen<br />

in its over five decades of independence with<br />

the strategic implementation of the Economic<br />

Transformation Programme (ETP), envisioned to<br />

carry our country to developed status by the year<br />

2020. The ETP’s grandeur vision is outlined under<br />

the 12 National Key Economic Areas (NKEAs).<br />

Klang Valley Mass Rapid Transit (<strong>KVMRT</strong>) is the<br />

single most important enabling factor for the<br />

crystalisation of the Greater Kuala Lumpur/Klang<br />

Valley NKEA, transforming Malaysia into a worldclass<br />

economic and tourism hub.<br />

As one of the Entry Point Projects highlighted<br />

under the Greater Kuala Lumpur/Klang Valley<br />

NKEA, building an integrated urban mass rapid<br />

transit system will provide greater connectivity for<br />

the public. This will also invigorate the local public<br />

transportation system by forming the backbone of<br />

Klang Valley’s Integrated Rail Network, consisting of<br />

the Light Rail Transit (Kelana Jaya and Ampang LRT<br />

Lines), KTM Komuter, Monorail, KLIA Ekspres and KLIA<br />

Transit.<br />

The MRT is a step ahead in placing Kuala Lumpur<br />

among the top cosmopolitan and most liveable cities<br />

in the world, enabling easy connectivity for up to<br />

1.2 million residents traversing between populated<br />

residential districts, business centres, commercial<br />

centres, and key employment areas in the urban and<br />

suburb corridors of the Klang Valley.<br />

13

<strong>KVMRT</strong> SBK Line:<br />

- Quick Facts<br />

51km in length<br />

9.5km is underground<br />

31 stops<br />

24 elevated stations<br />

7 underground stations<br />

14

MRT SUNGAI BULOH-SERDANG-PUTRAJAYA LINE<br />

(SSP LINE) ALIGNMENT<br />

15

S22 Bandar Malaysia South<br />

Provisional Station<br />

16

FORTIFYING TUNNEL STRENGTH WITH<br />

SEGMENTAL LININGS<br />

Segmental linings are traditionally the primary support layer in tunnel construction. Approximately 11,500<br />

rings of tunnel segment lining, with a thickness of 275mm are built for the <strong>KVMRT</strong> project to provide resistance<br />

against external pressure. They offer axial support for the thrust rams of TBM and maintain its progress.<br />

All completed tunnel lining are designed to withstand a variety of factors. Essentially they are:<br />

17

INTRODUCING INNOVATION - Steel Fibre Reinforced Concrete (SFRC)<br />

On this project, we introduced for the first time the use of Steel Fibre Reinforced Concrete (SFRC) for the tunnel<br />

lining segments. Of the 20 odd kilometres of tunnels on SBK Line, over 90% were lined by segments reinforced<br />

only with steel fibres. In the remaining 10%, rebar cages were used to increase the bending moment capacity to<br />

suit localised loading conditions.<br />

Advantages of SFRC Segments<br />

- The use of SFRC was advocated mainly for its benefits in improving durability due to its ability to reduce crack<br />

width and spalling as well as stop water path that causes corrosion of rebar.<br />

- The prevention of crack propagation also helps reduce the need for leak repairs in the tunnels and provides<br />

better freedom for installation of M&E fixtures on the linings without having to avoid rebars while drilling.<br />

- Productivity is increased as labour is no longer required for rebar cage fabrication and placement. Manpower for<br />

supervision and checks is also reduced.<br />

The Challenges<br />

18

19

THE UNDERGROUND<br />

CONSTRUCTION PROCESS<br />

Underground Works Sequence<br />

10 main TBMs were deployed to complete the 9.5km alignment<br />

with 4 launch shafts located in Semantan, Pudu, Cochrane and Maluri, spanning over 5 tunnel drives.<br />

Tunnelling Sequence<br />

pre escavated<br />

20

PLANNING & DESIGN OF<br />

UNDERGROUND STATIONS<br />

The early stages of <strong>KVMRT</strong> construction involved<br />

rigorous planning and design of the track alignment,<br />

stations, shafts and other underground structures to<br />

ensure the <strong>KVMRT</strong> system functions optimally with the<br />

following safety precautions.<br />

STANDARDS AND CODES OF PRACTICES<br />

All design work for the <strong>KVMRT</strong> project<br />

conforms to the Standards and Codes<br />

of Practiced issued by British Standard<br />

Institution (BSI).<br />

All underground stations and<br />

structures with public access are<br />

design for safe evacuation in case of<br />

fire and other emergency. These safety<br />

requirements are in accordance to the<br />

National Fire Protection Association<br />

(NFPA 13) for fixed guide way transit<br />

and passenger rail systems.<br />

19 21

ARCHITECTURAL DESIGN - AESTHETICS & FINISHES<br />

THE 7 UNDERGROUND STATIONS SBK LINE<br />

Theme: Transition – The Fusion of Our History and Modern<br />

Malaysia<br />

Theme: Confluence – Where Tradition meets Our<br />

Contemporary lifestyle<br />

Theme: Independence – A Tribute to the Spirit of Malaysia<br />

and Her Independence<br />

Theme: Dynamic – Vibrant Colours to Express the Dynamic<br />

Energy of Bukit Bintang<br />

Theme: Islamic Corporate – Reflecting a Developing<br />

Corporate Location and Dynamic Business Hub<br />

Theme: Urban Living – Reflecting Style, Fun and<br />

Cheerfulness<br />

Theme: New Generation – Revitalizing Older Communities<br />

via Connectivity<br />

22

THE SUCCESSFUL TBM<br />

BREAKTHRO<strong>UG</strong>HS OF SBK LINE<br />

Semantan to Muzium Negara<br />

(13/06/2013) (24/12/2014)<br />

Cochrane to Tun Razak Exchange<br />

(19/07/2013) (09/01/2014)<br />

Semantan to Muzium Negara<br />

(14/07/2013) (16/01/2014)<br />

Bukit Bintang to Pudu Launch Shaft<br />

(16/08/2014) (18/10/2014)<br />

Cochrane to Maluri<br />

(09/11/2013) (24/04/2014)<br />

Cochrane to Maluri<br />

(28/09/2013) (08/04/2014)<br />

Pudu Launch Shaft to Merdeka<br />

(05/05/2014) (06/10/2014)<br />

Bukit Bintang to Pudu Launch Shaft<br />

(24/07/2014) (16/10/2014)<br />

Muzium Negara to Pasar Seni<br />

(28/03/2014) (29/10/2014)<br />

Pudu Launch Shaft to Merdeka<br />

(04/11/2014) (04/01/2015)<br />

Merdeka to Pasar Seni<br />

(28/10/2014) (03/01/2015)<br />

23

TUNNELLING TRAINING ACADEMY (TTA)<br />

UPSKILLING ON YOUNG WORKFORCE<br />

Tunnelling Training Academy (TTA), launched by the<br />

fourth Prime Minister of Malaysia and the Perdana<br />

Leadership Foundation Honourary President Yang<br />

Amat Berbahagia Tun Dr. Mahathir Mohamad<br />

in December 2011, is MMC Gamuda’s initiative<br />

in developing a sustainable source of young<br />

Malaysians who are proficient in tunnelling which is<br />

a highly specialised area of work.<br />

Consistent with the Government’s aspirations to<br />

transform Malaysia into a high-income nation<br />

by the year 2020 through the creation of niche<br />

value-added employment opportunities in<br />

high technology industries, TTA is producing<br />

a steady stream of specialists, technicians and<br />

skilled manpower to support the roll-out of the<br />

underground works for the <strong>KVMRT</strong> project in the<br />

Klang Valley, as well as similar tunnelling projects in<br />

other parts of the world.<br />

At an initial cost of RM10 million for facilities set-up<br />

and development of skilled, technical and specialist<br />

training modules, TTA, since its inception has<br />

trained a total of 1000 skilled tunnelling workers<br />

for the industry, of which many are already making<br />

a decent living and making their way towards a<br />

rewarding career in tunnelling from working at<br />

various <strong>KVMRT</strong>, SBK Line underground project sites.<br />

<strong>KVMRT</strong> Lines that are part of the Klang Valley Urban Rail<br />

Development Plan.<br />

TTA is in collaboration with the Construction Industry<br />

Development Board (CIDB) in the assessment and award<br />

of the relevant skills certificates for participants. Also In<br />

cooperation with the government, students from Institut<br />

Kemahiran Belia Negara (IKBN) and Kolej Komuniti are<br />

recruited into TTA for industry-specific skills enhancement<br />

programmes.<br />

The range of facilities available at TTA include indoor<br />

classrooms, on-site tunnel boring machine cutterwheel,<br />

shotcrete mould, testing unit for annular gap filling<br />

(grouting), testing unit for foam production, laboratory<br />

apparatus, as well as equipment and devices for<br />

tunnelling data acquisition and analysis, and erector<br />

simulator for tunnel segment ring building.<br />

TTA is also expected to cater for the training<br />

needs of additional workers required for future<br />

Trainees undergoing training at the TTA<br />

24

TBM REFURBISHMENT PLANT<br />

Aerial view of TBM refurbishment plant at Waiko Engineering in Pusing, Perak<br />

The TBM refurbishment plant located at Waiko<br />

Engineering in Pusing, Perak was set up in 2015<br />

as one of the initiatives of the MRT Project Offset<br />

Programme, providing the platform to develop<br />

high technology in Malaysia through cooperation<br />

with foreign contractors and suppliers.<br />

The initiative, in partnership with Herrenknecht<br />

AG, would see the refurbishment, upgrading and<br />

modification of almost the entire fleet of TBMs<br />

deployed in the building of the Sungai Buloh-<br />

Kajang Line (SBK Line).<br />

Tunnelling Training Academy, supervised by experts from<br />

Herrenknecht AG.<br />

Under the initiative, Herrenknecht AG will collaborate<br />

with local steel and heavy engineering specialist, Waiko<br />

Engineering Works Sdn Bhd, to jointly carry out the TBM<br />

refurbishment works. Waiko is one of the beneficiaries for<br />

TBM refurbishment and components manufacturing in<br />

Malaysia, as part of the <strong>KVMRT</strong> offset agreement under<br />

MRT Corp and the Malaysian Industry-Government Group<br />

for High Technology.<br />

With the setting up of the refurbishment plant, it<br />

would enable the transfer of TBM expertise and<br />

refurbishment technology to Malaysia and its<br />

regional peers. It offers a new learning opportunity<br />

and exposure to our local talents to such training<br />

and experience in the highly-specialised operation<br />

of TBM refurbishment which helps Malaysian<br />

talents to be highly marketable worldwide.<br />

The refurbishment works is conducted by a<br />

team of experienced local engineers, supervisors<br />

and trained tunnel crew from MMC Gamuda’s<br />

VD TBM going through testing and inspection by the TTA crew<br />

25

BUILDING INFORMATION MODELLING (BIM)<br />

MMC Gamuda is one of the forerunners in the<br />

use of Building Information Modelling (BIM) in<br />

Malaysia, a technology to measure and validate<br />

site progress relating to construction works.<br />

It is currently being implemented for the<br />

underground portion of the Klang Valley MRT<br />

project and the SSP Line underground package<br />

is the first infrastructure project in Malaysia to<br />

be delivered using the BIM process.<br />

BIM, in accordance with the UK BIM level 2<br />

mandates, is the means by which everyone can<br />

understand a building through the use of a<br />

digital model built using data contributed in a<br />

collaborative fashion – before, during and after<br />

construction. The use of BIM is now mandated<br />

throughout the company.<br />

3D model for future Chan Sow Lin Station<br />

MMC Gamuda has also invested significant<br />

cost in setting up a BIM academy, the first in<br />

Malaysia, to train its staff so they could design<br />

and operate the automated process. The<br />

academy was set up to facilitate the human<br />

capital development process, which will train<br />

over 1,000 staff in BIM – in 3D, 4D and 5D<br />

workflows over the next two years and the<br />

training is based on the requirements of the UK<br />

PAS 1192-2.<br />

The training will help the change in the<br />

construction industry as far as reducing<br />

inefficiencies and wastage are concerned<br />

as well as help to add value in terms of<br />

local human capital development as more<br />

employees, including subcontractors, are<br />

trained to use BIM.<br />

BIM training at<br />

Shamelin<br />

3D model for Mechanical, Electrical & Plumbing (MEP)<br />

at Muzium Negara Station<br />

26

TECHNOLOGY & INNOVATION<br />

ADOPTED AT <strong>KVMRT</strong> UNDERGROUND SITES (SBK LINE)<br />

Adaptation of Surface Mining<br />

Technology for deep rock excavation<br />

in urban metro underground station<br />

Used at Tun Razak Exchange MRT Station Site<br />

- Replaces conventional drill and blast method<br />

with mechanised production using surface mining<br />

technology. Overcomes typical shortcomings<br />

associated with drill and blast like excessive<br />

vibration, noise and fly rock.<br />

- Circumvents restrictions imposed by authorities<br />

on blasting hence improves productivity in<br />

construction.<br />

- First in Malaysia to successfully complete an<br />

underground metro station excavation using<br />

surface miners.<br />

Low Headroom Piling Machine<br />

Used at Maluri MRT Station Site<br />

- Customised bore piling machine working in<br />

headroom-constrained condition.<br />

- Developed jointly for bore piling works<br />

underneath high tension cables at Maluri<br />

Underground Station.<br />

- Height of boring rig reduced from conventional<br />

15.8m to 7.5m to work safely under the height<br />

clearance made available at 9.0m.<br />

- Prevented the need to relocate the high tension<br />

cables which can be costly and time consuming.<br />

- The new development was used subsequently in<br />

projects in Australia.<br />

- World’s shortest bore piling rig.<br />

Silent Piler for hard ground<br />

Used at Bukit Bintang MRT Station Site<br />

- First of its kind used in Malaysia.<br />

- Compact and light that it can eliminate or<br />

minimise negative social impact from vibration,<br />

noise and discharged of soils.<br />

- High piling quality with no risk of machines<br />

overturning.<br />

- Allows piling work to be carried out at<br />

constrained spaces and slopes.<br />

- Helps to shorten the construction duration.<br />

- World’s shortest bored piling rig.<br />

27

Impact Protection Vehicle (IPV)<br />

Used extensively at all Sites<br />

- First of its kind introduced in Malaysia.<br />

- To enhance safety when working in live traffic areas<br />

where closures are required.<br />

- Mobile Traffic Management System that comes in<br />

the form of a lorry-mounted crash attenuator and<br />

crash cushion.<br />

- It protects workers when carrying out essential<br />

traffic management and road works.<br />

- Also provides protection for traffic personnel<br />

working in front of the lorry. Mandatory in<br />

countries like Britain, US and many parts of Europe, saves<br />

the hassle of having to use flagmen and putting up with<br />

human error.<br />

- Since its introduction, other highway operators in Malaysia<br />

have shown interest in using the IPV for safer working<br />

environment.<br />

- Provides greater control during temporary traffic<br />

management operations and enhances safety for road<br />

users and MMC Gamuda’s personnel.<br />

- IPV serves to absorb side or rear impact from oncoming<br />

vehicles and reduces momentum which in turn prevents<br />

serious injury.<br />

Special Ground Anchor Drilling &<br />

Hacking Machine (Low Head Room<br />

Hacker)<br />

Used at Pasar Seni MRT Station Site<br />

- Brought in from Singapore, first to be used in<br />

Malaysia.<br />

- Can fit into locations as low as 1.7m.<br />

- Can handle variable soil and groundwater<br />

conditions.<br />

- Able to hack hard material (concrete) and excavate<br />

in confined spaces.<br />

- Rarely used due to its high technology involved<br />

and unique size.<br />

- Fully electrically-powered machine for excavation<br />

and hacking.<br />

- Uses wireless system and is operated using remote<br />

control.<br />

- It can be used at confined spaces and corners. Its small<br />

size allows easy manoeuvrability and accessibility.<br />

- By using the machine, it can make a difference of at<br />

least 8 months to the timeline, compared to the existing<br />

methods used and it is cost-efficient<br />

28

FIRST IN MALAYSIA<br />

– INITIATIVES by SAFETY, HEALTH & ENVIRONMENT DEPARTMENT<br />

Flashover Training<br />

MMC Gamuda <strong>KVMRT</strong> (T) Sdn Bhd (MGKT) is<br />

committed to ensuring Safety and Quality is given<br />

top priority. We have established a safe & healthy<br />

working culture throughout the organization,<br />

aiming at preventing injuries and ill-health to<br />

our employees, subcontractors, public and third<br />

parties as well as preventing any damage or loss<br />

to property, plant & equipment.<br />

One of the biggest risks in tunnelling works is<br />

when there is fire in a tunnel. With the confined<br />

space and lack of permanent ventilation, the<br />

speed, direction and layering of the smoke can<br />

cause one’s life.<br />

Flashover Training in session<br />

To ensure the safety of our tunnellers, special<br />

training called flashover training was introduced<br />

to the staff. The flashover training is a first of its<br />

kind in Malaysia, introduced by MGKT in Malaysia.<br />

A flashover is a condition where an explosive<br />

burst occurs when a fire is so hot that gases and<br />

smoke ignite. The training includes exposing<br />

the trainees on how to recognise the signs of a<br />

flashover and the risk involved.<br />

Flashover Demonstration<br />

Trained & Qualified First responders Serving the Project<br />

The first of such an initiative by a Malaysian contractor, we initiated our very own Paramedic and Firefighting<br />

teams to respond to any incidents, round-the-clock.<br />

29

AWARDS & ACHIEVEMENTS<br />

<strong>2019</strong> International Safety Awards,<br />

For exemplary management of health,<br />

safety and environmental risks<br />

Winner for Community Engagement<br />

Category<br />

Five Star in British Safety Council<br />

Health and Safety Audit<br />

A significant 1st in Malaysia<br />

Highly Commended for<br />

Community Engagement Award Category<br />

BEST PROJECT AWARD<br />

(INFRASTRUCTURE)<br />

Malaysian Construction Industry<br />

Excellence Awards (MCIEA) 2017<br />

INNOVATION AWARD<br />

Variable Density in Tunnelling Technique,<br />

Malaysian Construction Industry<br />

Excellence Awards (MCIEA) 2017<br />

Derek Eng Jia Yih named ITA<br />

Young Tunneller Of The Year<br />

2015 International Safety Awards,<br />

For exemplary management of health,<br />

safety and environmental risks<br />

Honorary Certification for Safety and Health year<br />

2015 during construction MRT TRX Station,<br />

by Department of Occupational Safety and<br />

Health<br />

Technical Innovation<br />

Variable Density TBM - MRT Line 1<br />

30

For more<br />

information<br />

about the project,<br />

please visit our<br />

MRT Info Centre<br />

For more information,<br />

visit our MRT INFO CENTRE<br />

or call our MRT HOTLINE<br />

at 1800-82-6868<br />

Tel: +603-2385 8000<br />

MMCGamudaMRT<br />

MMCGamudaMRT<br />

MMCGamudaMRT<br />

MMCGamudaMRT

![[Exhibit 6] Tunnelling Virtual Reality Walk](https://img.yumpu.com/62890814/1/184x260/exhibit-6-tunnelling-virtual-reality-walk.jpg?quality=85)

![[Exhibit 2] Autonomous Tunnel Boring Machine](https://img.yumpu.com/62883468/1/190x107/exhibit-2-autonomous-tunnel-boring-machine.jpg?quality=85)

![[Exhibit 1] Tunnelling Centralised Command Control Centre (TC4) Statistics](https://img.yumpu.com/62879681/1/190x107/exhibit-1-tunnelling-centralised-command-control-centre-tc4-statistics.jpg?quality=85)