MTL - BROCHURE 2018 SINGLE PAGES

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

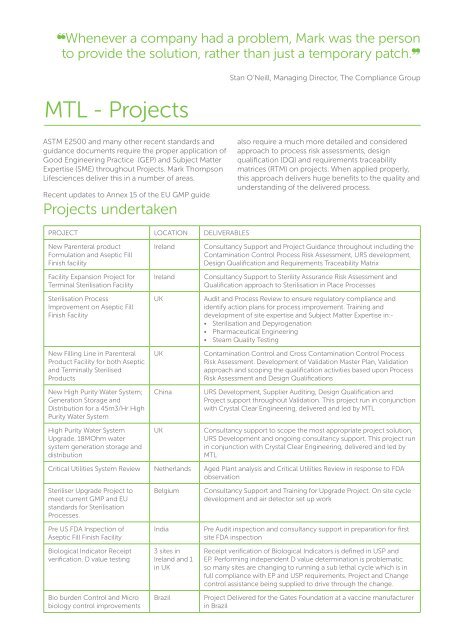

❝Whenever a company had a problem, Mark was the person<br />

to provide the solution, rather than just a temporary patch.❞<br />

<strong>MTL</strong> - Projects<br />

Stan O’Neill, Managing Director, The Compliance Group<br />

ASTM E2500 and many other recent standards and<br />

guidance documents require the proper application of<br />

Good Engineering Practice (GEP) and Subject Matter<br />

Expertise (SME) throughout Projects. Mark Thompson<br />

Lifesciences deliver this in a number of areas.<br />

Recent updates to Annex 15 of the EU GMP guide<br />

Projects undertaken<br />

also require a much more detailed and considered<br />

approach to process risk assessments, design<br />

qualification (DQ) and requirements traceability<br />

matrices (RTM) on projects. When applied properly,<br />

this approach delivers huge benefits to the quality and<br />

understanding of the delivered process.<br />

PROJECT LOCATION DELIVERABLES<br />

New Parenteral product<br />

Formulation and Aseptic Fill<br />

Finish facility<br />

Facility Expansion Project for<br />

Terminal Sterilisation Facility<br />

Sterilisation Process<br />

Improvement on Aseptic Fill<br />

Finish Facility<br />

New Filling Line in Parenteral<br />

Product Facility for both Aseptic<br />

and Terminally Sterilised<br />

Products<br />

New High Purity Water System;<br />

Generation Storage and<br />

Distribution for a 45m3/Hr High<br />

Purity Water System<br />

High Purity Water System<br />

Upgrade. 18MOhm water<br />

system generation storage and<br />

distribution<br />

Ireland<br />

Ireland<br />

UK<br />

UK<br />

China<br />

UK<br />

Consultancy Support and Project Guidance throughout including the<br />

Contamination Control Process Risk Assessment, URS development,<br />

Design Qualification and Requirements Traceability Matrix<br />

Consultancy Support to Sterility Assurance Risk Assessment and<br />

Qualification approach to Sterilisation in Place Processes<br />

Audit and Process Review to ensure regulatory compliance and<br />

identify action plans for process improvement. Training and<br />

development of site expertise and Subject Matter Expertise in:-<br />

• Sterilisation and Depyrogenation<br />

• Pharmaceutical Engineering<br />

• Steam Quality Testing<br />

Contamination Control and Cross Contamination Control Process<br />

Risk Assessment. Development of Validation Master Plan, Validation<br />

approach and scoping the qualification activities based upon Process<br />

Risk Assessment and Design Qualifications<br />

URS Development, Supplier Auditing, Design Qualification and<br />

Project support throughout Validation. This project run in conjunction<br />

with Crystal Clear Engineering, delivered and led by <strong>MTL</strong><br />

Consultancy support to scope the most appropriate project solution,<br />

URS Development and ongoing consultancy support. This project run<br />

in conjunction with Crystal Clear Engineering, delivered and led by<br />

<strong>MTL</strong><br />

Critical Utilities System Review Netherlands Aged Plant analysis and Critical Utilities Review in response to FDA<br />

observation<br />

Steriliser Upgrade Project to<br />

meet current GMP and EU<br />

standards for Sterilisation<br />

Processes.<br />

Pre US FDA Inspection of<br />

Aseptic Fill Finish Facility<br />

Biological Indicator Receipt<br />

verification. D value testing<br />

Bio burden Control and Micro<br />

biology control improvements<br />

Belgium<br />

India<br />

3 sites in<br />

Ireland and 1<br />

in UK<br />

Brazil<br />

Consultancy Support and Training for Upgrade Project. On site cycle<br />

development and air detector set up work<br />

Pre Audit inspection and consultancy support in preparation for first<br />

site FDA inspection<br />

Receipt verification of Biological Indicators is defined in USP and<br />

EP. Performing independent D value determination is problematic<br />

so many sites are changing to running a sub lethal cycle which is in<br />

full compliance with EP and USP requirements. Project and Change<br />

control assistance being supplied to drive through the change.<br />

Project Delivered for the Gates Foundation at a vaccine manufacturer<br />

in Brazil