National Scientific 2008-9 Catalogue

This catalogue contains product details of products from National Scientific. If you have any questions about National Scientific products or wish to discuss the pricing and delivery of products from this manufacturer, or any of the many other Manufacturers we represent, please do not hesitate to contact us either by email Sales@greyhoundchrom.com or rachel@greyhoundchrom.com (Greyhound Chromatography’s Sales Manager). We are proud of our long-standing relationships with our customers and agents. We value our agent network highly and are constantly looking to appoint new agents with the right expertise, in areas where we are not represented. Please email sales@greyhoundchrom.com if you are interested in becoming one of our agents. Visit https://www.greyhoundchrom.com for a full range of Chromatography consumables, including Certified Reference Standards and Materials, Solvents, Reagents and Laboratory Chemicals.

This catalogue contains product details of products from National Scientific. If you have any questions about National Scientific products or wish to discuss the pricing and delivery of products from this manufacturer, or any of the many other Manufacturers we represent, please do not hesitate to contact us either by email Sales@greyhoundchrom.com or rachel@greyhoundchrom.com (Greyhound Chromatography’s Sales Manager).

We are proud of our long-standing relationships with our customers and agents. We value our agent network highly and are constantly looking to appoint new agents with the right expertise, in areas where we are not represented. Please email sales@greyhoundchrom.com if you are interested in becoming one of our agents.

Visit https://www.greyhoundchrom.com for a full range of Chromatography consumables, including Certified Reference Standards and Materials, Solvents, Reagents and Laboratory Chemicals.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

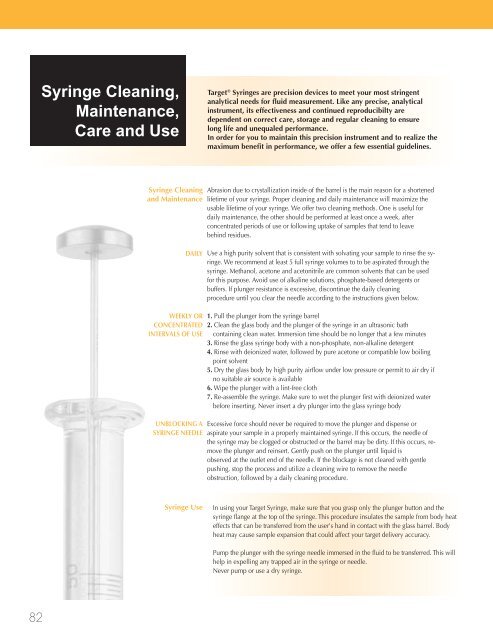

Syringe Cleaning,<br />

Maintenance,<br />

Care and Use<br />

Target ® Syringes are precision devices to meet your most stringent<br />

analytical needs for fluid measurement. Like any precise, analytical<br />

instrument, its effectiveness and continued reproducibilty are<br />

dependent on correct care, storage and regular cleaning to ensure<br />

long life and unequaled performance.<br />

In order for you to maintain this precision instrument and to realize the<br />

maximum benefit in performance, we offer a few essential guidelines.<br />

Syringe Cleaning<br />

and Maintenance<br />

DAILY<br />

WEEKLY OR<br />

CONCENTRATED<br />

INTERVALS OF USE<br />

UNBLOCKING A<br />

SYRINGE NEEDLE<br />

Abrasion due to crystallization inside of the barrel is the main reason for a shortened<br />

lifetime of your syringe. Proper cleaning and daily maintenance will maximize the<br />

usable lifetime of your syringe. We offer two cleaning methods. One is useful for<br />

daily maintenance, the other should be performed at least once a week, after<br />

concentrated periods of use or following uptake of samples that tend to leave<br />

behind residues.<br />

Use a high purity solvent that is consistent with solvating your sample to rinse the syringe.<br />

We recommend at least 5 full syringe volumes to to be aspirated through the<br />

syringe. Methanol, acetone and acetonitrile are common solvents that can be used<br />

for this purpose. Avoid use of alkaline solutions, phosphate-based detergents or<br />

buffers. If plunger resistance is excessive, discontinue the daily cleaning<br />

procedure until you clear the needle according to the instructions given below.<br />

1. Pull the plunger from the syringe barrel<br />

2. Clean the glass body and the plunger of the syringe in an ultrasonic bath<br />

containing clean water. Immersion time should be no longer that a few minutes<br />

3. Rinse the glass syringe body with a non-phosphate, non-alkaline detergent<br />

4. Rinse with deionized water, followed by pure acetone or compatible low boiling<br />

point solvent<br />

5. Dry the glass body by high purity airflow under low pressure or permit to air dry if<br />

no suitable air source is available<br />

6. Wipe the plunger with a lint-free cloth<br />

7. Re-assemble the syringe. Make sure to wet the plunger first with deionized water<br />

before inserting. Never insert a dry plunger into the glass syringe body<br />

Excessive force should never be required to move the plunger and dispense or<br />

aspirate your sample in a properly maintained syringe. If this occurs, the needle of<br />

the syringe may be clogged or obstructed or the barrel may be dirty. If this occurs, remove<br />

the plunger and reinsert. Gently push on the plunger until liquid is<br />

observed at the outlet end of the needle. If the blockage is not cleared with gentle<br />

pushing, stop the process and utilize a cleaning wire to remove the needle<br />

obstruction, followed by a daily cleaning procedure.<br />

Syringe Use<br />

In using your Target Syringe, make sure that you grasp only the plunger button and the<br />

syringe flange at the top of the syringe. This procedure insulates the sample from body heat<br />

effects that can be transferred from the user's hand in contact with the glass barrel. Body<br />

heat may cause sample expansion that could affect your target delivery accuracy.<br />

Pump the plunger with the syringe needle immersed in the fluid to be transferred. This will<br />

help in expelling any trapped air in the syringe or needle.<br />

Never pump or use a dry syringe.<br />

82