5 Design Elements for Safe, Heavy-duty Racking

Most fabricators have some type of heavy-duty racking, and the specifics behind their design shouldn’t be overlooked. Poorly designed racking can be one of the most dangerous hazards on the shop floor.

Most fabricators have some type of heavy-duty racking, and the specifics behind their design shouldn’t be overlooked. Poorly designed racking can be one of the most dangerous hazards on the shop floor.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

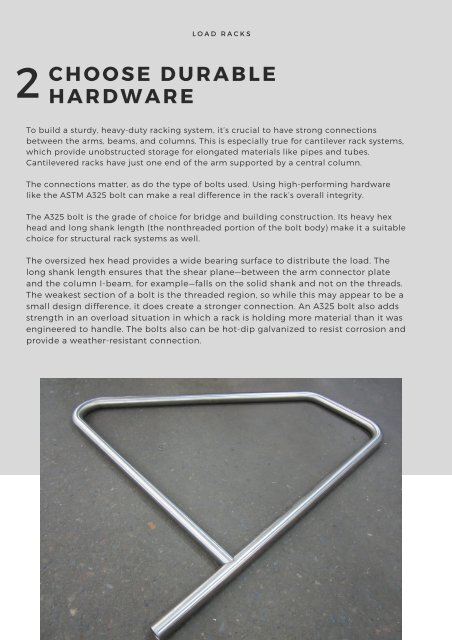

uild a sturdy, heavy-<strong>duty</strong> racking system, it’s crucial to have strong connections<br />

To<br />

the arms, beams, and columns. This is especially true <strong>for</strong> cantilever rack systems,<br />

between<br />

provide unobstructed storage <strong>for</strong> elongated materials like pipes and tubes.<br />

which<br />

racks have just one end of the arm supported by a central column.<br />

Cantilevered<br />

connections matter, as do the type of bolts used. Using high-per<strong>for</strong>ming hardware<br />

The<br />

the ASTM A325 bolt can make a real difference in the rack’s overall integrity.<br />

like<br />

A325 bolt is the grade of choice <strong>for</strong> bridge and building construction. Its heavy hex<br />

The<br />

and long shank length (the nonthreaded portion of the bolt body) make it a suitable<br />

head<br />

oversized hex head provides a wide bearing surface to distribute the load. The<br />

The<br />

shank length ensures that the shear plane—between the arm connector plate<br />

long<br />

the column I-beam, <strong>for</strong> example—falls on the solid shank and not on the threads.<br />

and<br />

weakest section of a bolt is the threaded region, so while this may appear to be a<br />

The<br />

design difference, it does create a stronger connection. An A325 bolt also adds<br />

small<br />

in an overload situation in which a rack is holding more material than it was<br />

strength<br />

to handle. The bolts also can be hot-dip galvanized to resist corrosion and<br />

engineered<br />

a weather-resistant connection.<br />

provide<br />

L O A D R A C K S<br />

C H O O S E D U R A B L E<br />

2<br />

H A R D W A R E<br />

choice <strong>for</strong> structural rack systems as well.