Modular Housing and Relocatable Structure Application Channel-Ex Saferwood: Fire Retardant Treated Wood Products for Interior & Exterior Applications

Channel-Ex Saferwood line of flame resistant wood products are some of the most extensively tested/validated at wide range of structural, internal, external and wild fire scenarios in the industry. Channel-Ex Saferwood is available as the Interior & Exterior application Plywood, Lumber, LVL, Poles/stakes, Fascia, Siding, & Shake/Shingles.

Channel-Ex Saferwood line of flame resistant wood products are some of the most extensively tested/validated at wide range of structural, internal, external and wild fire scenarios in the industry. Channel-Ex Saferwood is available as the Interior & Exterior application Plywood, Lumber, LVL, Poles/stakes, Fascia, Siding, & Shake/Shingles.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

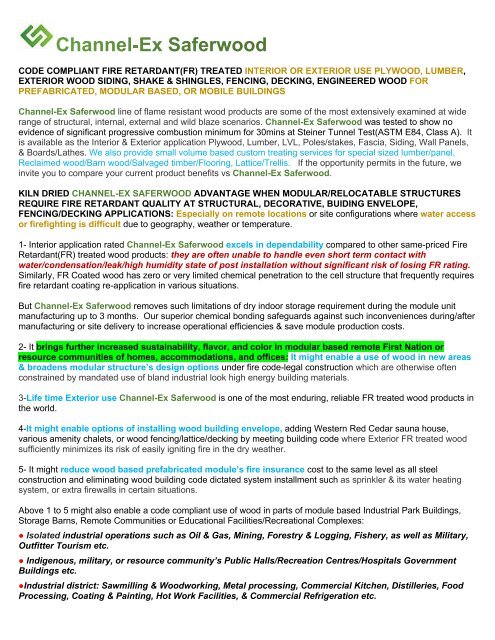

CODE COMPLIANT FIRE RETARDANT(FR) TREATED INTERIOR OR EXTERIOR USE PLYWOOD, LUMBER,<br />

EXTERIOR WOOD SIDING, SHAKE & SHINGLES, FENCING, DECKING, ENGINEERED WOOD FOR<br />

PREFABRICATED, MODULAR BASED, OR MOBILE BUILDINGS<br />

<strong>Channel</strong>-<strong>Ex</strong> <strong>Saferwood</strong> line of flame resistant wood products are some of the most extensively examined at wide<br />

range of structural, internal, external <strong>and</strong> wild blaze scenarios. <strong>Channel</strong>-<strong>Ex</strong> <strong>Saferwood</strong> was tested to show no<br />

evidence of significant progressive combustion minimum <strong>for</strong> 30mins at Steiner Tunnel Test(ASTM E84, Class A). It<br />

is available as the <strong>Interior</strong> & <strong>Ex</strong>terior application Plywood, Lumber, LVL, Poles/stakes, Fascia, Siding, Wall Panels,<br />

& Boards/Lathes. We also provide small volume based custom treating services <strong>for</strong> special sized lumber/panel,<br />

Reclaimed wood/Barn wood/Salvaged timber/Flooring, Lattice/Trellis. If the opportunity permits in the future, we<br />

invite you to compare your current product benefits vs <strong>Channel</strong>-<strong>Ex</strong> <strong>Saferwood</strong>.<br />

KILN DRIED CHANNEL-EX SAFERWOOD ADVANTAGE WHEN MODULAR/RELOCATABLE STRUCTURES<br />

REQUIRE FIRE RETARDANT QUALITY AT STRUCTURAL, DECORATIVE, BUIDING ENVELOPE,<br />

FENCING/DECKING APPLICATIONS: Especially on remote locations or site configurations where water access<br />

or firefighting is difficult due to geography, weather or temperature.<br />

1- <strong>Interior</strong> application rated <strong>Channel</strong>-<strong>Ex</strong> <strong>Saferwood</strong> excels in dependability compared to other same-priced <strong>Fire</strong><br />

<strong>Retardant</strong>(FR) treated wood products: they are often unable to h<strong>and</strong>le even short term contact with<br />

water/condensation/leak/high humidity state of post installation without significant risk of losing FR rating.<br />

Similarly, FR Coated wood has zero or very limited chemical penetration to the cell structure that frequently requires<br />

fire retardant coating re-application in various situations.<br />

But <strong>Channel</strong>-<strong>Ex</strong> <strong>Saferwood</strong> removes such limitations of dry indoor storage requirement during the module unit<br />

manufacturing up to 3 months. Our superior chemical bonding safeguards against such inconveniences during/after<br />

manufacturing or site delivery to increase operational efficiencies & save module production costs.<br />

2- It brings further increased sustainability, flavor, <strong>and</strong> color in modular based remote First Nation or<br />

resource communities of homes, accommodations, <strong>and</strong> offices: It might enable a use of wood in new areas<br />

& broadens modular structure’s design options under fire code-legal construction which are otherwise often<br />

constrained by m<strong>and</strong>ated use of bl<strong>and</strong> industrial look high energy building materials.<br />

3-Life time <strong>Ex</strong>terior use <strong>Channel</strong>-<strong>Ex</strong> <strong>Saferwood</strong> is one of the most enduring, reliable FR treated wood products in<br />

the world.<br />

4-It might enable options of installing wood building envelope, adding Western Red Cedar sauna house,<br />

various amenity chalets, or wood fencing/lattice/decking by meeting building code where <strong>Ex</strong>terior FR treated wood<br />

sufficiently minimizes its risk of easily igniting fire in the dry weather.<br />

5- It might reduce wood based prefabricated module’s fire insurance cost to the same level as all steel<br />

construction <strong>and</strong> eliminating wood building code dictated system installment such as sprinkler & its water heating<br />

system, or extra firewalls in certain situations.<br />

Above 1 to 5 might also enable a code compliant use of wood in parts of module based Industrial Park Buildings,<br />

Storage Barns, Remote Communities or Educational Facilities/Recreational Complexes:<br />

● Isolated industrial operations such as Oil & Gas, Mining, Forestry & Logging, Fishery, as well as Military,<br />

Outfitter Tourism etc.<br />

● Indigenous, military, or resource community’s Public Halls/Recreation Centres/Hospitals Government<br />

Buildings etc.<br />

●Industrial district: Sawmilling & <strong>Wood</strong>working, Metal processing, Commercial Kitchen, Distilleries, Food<br />

Processing, Coating & Painting, Hot Work Facilities, & Commercial Refrigeration etc.

● Storages <strong>for</strong> such as food, hay, wood, certain minerals, pharmaceutical products, plastic as well as where<br />

combustible pallets or items are stocked. Barns/Farm Buildings/Sheds.<br />

OUR COMPANY:<br />

ABOUT CHANNEL-EX:<br />

Custom outsourcing manufacturer of <strong>Fire</strong> <strong>Retardant</strong> Plywood/Lumber(<strong>Ex</strong>terior <strong>and</strong> <strong>Interior</strong> applications,<br />

US/Canadian building code compliant: CLASS A), <strong>and</strong> other products including Western Red Cedar(WRC) located<br />

in Vancouver BC. We have been working closely over 20yrs with the leading <strong>Fire</strong> <strong>Retardant</strong> <strong>Wood</strong> Treatment<br />

company Chemco of Ferndale WA, USA.<br />

<strong>Channel</strong>-<strong>Ex</strong> selects consistent long-term quality log & fibre suppliers to develop a strong relationship from its<br />

inception in 2005. Since our sister company <strong>Channel</strong> Original(CO) was established in 1998 in Yokohama Japan,<br />

CO has grown in sizes with 5 WRC sales offices/distribution centres as a producer-supplier of Japan’s dominant<br />

fire retardant treated WRC exterior siding product WILL WALL & the largest high value WRC lumber dealer<br />

across the country, with a prized specialty Yaku Sugi Cedar lumber manufacturing facility in the Southern Japan,<br />

<strong>and</strong> a Hokkaido Hardwood Flooring plant in its North. <strong>Channel</strong>-<strong>Ex</strong> likewise has been managing CO's fire retardant<br />

wood & other product procurement, production, & quality control activities in North America.<br />

<strong>Channel</strong>-<strong>Ex</strong> web site is: http://www.channel-ex.com<br />

ABOUT CHEMCO:<br />

Our <strong>Channel</strong>-<strong>Ex</strong> <strong>Saferwood</strong> partner <strong>and</strong> one of the world’s premier treatment companies <strong>for</strong> fire retardant wood<br />

<strong>and</strong> engineered wood products. It leads the North American <strong>Fire</strong> <strong>Retardant</strong> <strong>Wood</strong> Treatment industry by becoming<br />

the first technology supplier of Cedar Shakes <strong>and</strong> Shingle <strong>for</strong> roof application in the state of Cali<strong>for</strong>nia.<br />

<strong>Channel</strong> Original <strong>and</strong> Chemco collaborated to create the first FR treated siding product that was able to pass the<br />

stringent testing required in Japan <strong>and</strong> gained approvals <strong>for</strong> semi-combustible <strong>and</strong> non-combustible ratings.<br />

Chemco web site is: https://www.chemco.org<br />

ADVANTAGE FOR INDUSTRIAL APPLICATION:<br />

In addition to <strong>Modular</strong> based building exterior cladding/interior decoration & structural application, <strong>Channel</strong>-ex<br />

<strong>Saferwood</strong> can benefit Industrial sector with its introduction of flame resistant raw material wood <strong>for</strong> FR plank wood<br />

or LVL Scaffolding, Formwork, Plywood cover of Construction Hoistway & other Temporary <strong>Structure</strong>s, Plywood<br />

Welding Mat, Marine Timber, Electrical Equipment mount/structures, Utility Poles, FR<br />

Crating/Pallet/Dunnage/Cradle, & industrial Mat applications.<br />

PRODUCT PRICING:<br />

CURRENT OFFER:<br />

INTERIOR USE FRT PRODUCTS, THIS PRODUCT ALLOWS TEMPORARY OUTSIDE STORAGE UPTO<br />

3 MONTHS.<br />

EXTEROIR PRODUCT PRICE IS ABOUT +15% of INTERIOR USE PRODUCTS.<br />

PLYWOOD: 4x8'<br />

Specie: Douglas Fir<br />

Thickness: 3/8"(9.5mm), 1/2"(12.5mm), 5/8"(15.5mm), 3/4"(18.5mm), 1”(25mm)<br />

LUMBER:<br />

Specie: Douglas Fir, SPF, Hemlock, Western Red Cedar<br />

Size: 2x3, 2X4, 2X6, 8-20'.

CUSTOM TREATMENT OF WOOD SIDING, UTILITY POLES, TIMBERS, LVL IS PROVIDED<br />

specie: SPF, Western Red Cedar, Douglas Fir, Hemlock, Aspen<br />

Should you have a question about our products, please feel free to inquire us at Ben@channel-ex.com or 604-989-<br />

5087.<br />

Ben Rusuisiak<br />

Specialty <strong>Wood</strong> <strong>Products</strong>, North American Sales<br />

<strong>Channel</strong>-<strong>Ex</strong> Trading Corp.<br />

1001-543 Granville Street, Vancouver, BC V6C1X8 Canada<br />

Office: 1(604)416-1450<br />

Fax: 1(604)416-1451<br />

Cell: 1(604)989-5087<br />

E-mail: ben@channel-ex.com<br />

Web: www.channel-ex.com