External Surface Sheathing Systems Catalogue

External Surface Sheathing Systems Catalogue

External Surface Sheathing Systems Catalogue

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

22<br />

Blue'Safe Mavi Kale ––––––––––– Pre-Application Structural Conditions and Job technique in <strong>External</strong><br />

<strong>Surface</strong> Thermal Insulation<br />

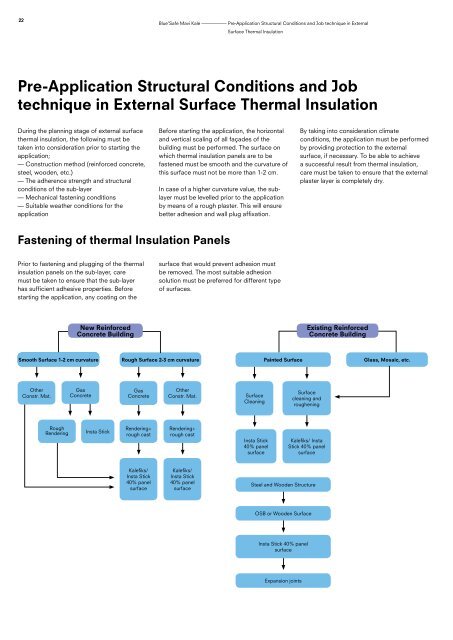

Pre-Application Structural Conditions and Job<br />

technique in <strong>External</strong> <strong>Surface</strong> Thermal Insulation<br />

During the planning stage of external surface<br />

thermal insulation, the following must be<br />

taken into consideration prior to starting the<br />

application;<br />

— Construction method (reinforced concrete,<br />

steel, wooden, etc.)<br />

— The adherence strength and structural<br />

conditions of the sub-layer<br />

— Mechanical fastening conditions<br />

— Suitable weather conditions for the<br />

application<br />

Prior to fastening and plugging of the thermal<br />

insulation panels on the sub-layer, care<br />

must be taken to ensure that the sub-layer<br />

has sufficient adhesive properties. Before<br />

starting the application, any coating on the<br />

Smooth <strong>Surface</strong> 1-2 cm curvature<br />

Other<br />

Constr. Mat.<br />

Rough<br />

Rendering<br />

New Reinforced<br />

Concrete Building<br />

Gas<br />

Concrete<br />

Insta Stick<br />

Gas<br />

Concrete<br />

Rendering+<br />

rough cast<br />

Kalefiks/<br />

Insta Stick<br />

40% panel<br />

surface<br />

Before starting the application, the horizontal<br />

and vertical scaling of all façades of the<br />

building must be performed. The surface on<br />

which thermal insulation panels are to be<br />

fastened must be smooth and the curvature of<br />

this surface must not be more than 1-2 cm.<br />

In case of a higher curvature value, the sublayer<br />

must be levelled prior to the application<br />

by means of a rough plaster. This will ensure<br />

better adhesion and wall plug affixation.<br />

Fastening of thermal Insulation Panels<br />

surface that would prevent adhesion must<br />

be removed. The most suitable adhesion<br />

solution must be preferred for different type<br />

of surfaces.<br />

Rough <strong>Surface</strong> 2-3 cm curvature<br />

Other<br />

Constr. Mat.<br />

Rendering+<br />

rough cast<br />

Kalefiks/<br />

Insta Stick<br />

40% panel<br />

surface<br />

<strong>Surface</strong><br />

Cleaning<br />

Insta Stick<br />

40% panel<br />

surface<br />

Painted <strong>Surface</strong><br />

Steel and Wooden Structure<br />

OSB or Wooden <strong>Surface</strong><br />

Insta Stick 40% panel<br />

surface<br />

Expansion joints<br />

By taking into consideration climate<br />

conditions, the application must be performed<br />

by providing protection to the external<br />

surface, if necessary. To be able to achieve<br />

a successful result from thermal insulation,<br />

care must be taken to ensure that the external<br />

plaster layer is completely dry.<br />

<strong>Surface</strong><br />

cleaning and<br />

roughening<br />

Kalefiks/ Insta<br />

Stick 40% panel<br />

surface<br />

Existing Reinforced<br />

Concrete Building<br />

Glass, Mosaic, etc.