50th Bro V2 18-11

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2000s<br />

2000s<br />

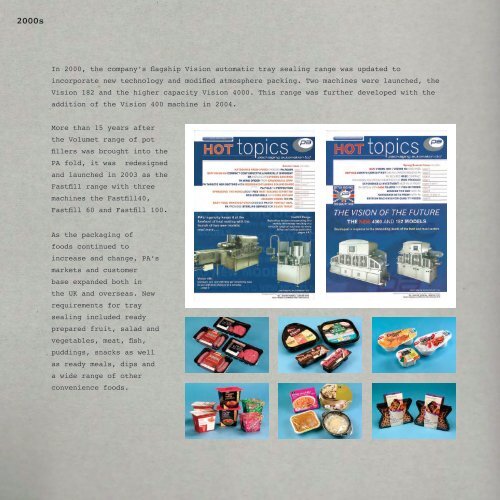

In 2000, the company’s flagship Vision automatic tray sealing range was updated to<br />

incorporate new technology and modified atmosphere packing. Two machines were launched, the<br />

Vision <strong>18</strong>2 and the higher capacity Vision 4000. This range was further developed with the<br />

addition of the Vision 400 machine in 2004.<br />

More than 15 years after<br />

the Volumet range of pot<br />

fillers was brought into the<br />

PA fold, it was redesigned<br />

and launched in 2003 as the<br />

Fastfill range with three<br />

machines the Fastfill40,<br />

Fastfill 60 and Fastfill 100.<br />

As the packaging of<br />

foods continued to<br />

increase and change, PA’s<br />

markets and customer<br />

base expanded both in<br />

the UK and overseas. New<br />

requirements for tray<br />

sealing included ready<br />

prepared fruit, salad and<br />

vegetables, meat, fish,<br />

puddings, snacks as well<br />

as ready meals, dips and<br />

a wide range of other<br />

convenience foods.<br />

The high speed fully electric single lane eclipse X demonstrates<br />

the latest in tray sealing technology. Speeds of up to 150 packs<br />

per minute single lane highlight the advancements in sealing<br />

capabilities. Reduced energy consumption, increased efficiency,<br />

ruggedness and operator friendliness have all been achieved with<br />

this design.<br />

The eclipse range of equipment, bring to the tray sealing market<br />

versatility and unique developments born out of PA’s 50 years of<br />

experience in the industry.<br />

eclipse<br />

• E-Seal - fully electrical machine requiring zero air<br />

• Can seal up to 150 packs per minute single lane<br />

• High speed (ITS) Intelligent Transfer System<br />

• Ultimate in sealing flexibility<br />

• 2 minute tool changeovers<br />

• Energy efficient<br />

• Indisputable reliability<br />

• Environmental considerations incorporated into the<br />

design<br />

• Ultra lightweight and quick release tooling<br />

• Inbuilt TDS (Tool Docking System) automatically aligns<br />

electrical and gas connectors on the tool<br />

eclipse x<br />

In early 2010 the Eclipse range<br />

of equipment was unveiled by the<br />

company. The range was launched<br />

in answer to a requirement from<br />

the food industry for quicker,<br />

more efficient, flexible machines.<br />

It also accommodated the high<br />

speed transfer of lower viscosity<br />

products into the machine without<br />

spilling them. HMI operated servos<br />

now controlled all of the moving<br />

parts of the machine.<br />

The twin lane high speed eclipse<br />

machine was launched at the Foodex<br />

show in 2010. This was soon<br />

followed by the smaller SL3 and<br />

SL4 machines in 20<strong>11</strong> which allowed<br />

users to make the transition from<br />

pneumatics to completely electric<br />

machines.<br />

Subsequently the PA<strong>18</strong>2 which was<br />

first designed in 1976 was brought<br />

bang up to date and was also made<br />

fully electric and relaunched as<br />

the Eclipse R.<br />

In 2013 a great leap forward in<br />

technology enabled the development<br />

the very high speed sealing with<br />

the fastest throughput of any<br />

single lane flexible tray sealer at<br />

150 packs per minute.