Advantages of Laser Cutting Technique - Form2000 Sheetmetal

Laser cut sheet metal technology is widely used in manufacturing and production industry due to its various advantages. Read this document to gain more insights about laser technology for cutting and shaping the sheet metals. For more information visit https://www.form2000.com.au/capabilities/laser-cutting.php

Laser cut sheet metal technology is widely used in manufacturing and production industry due to its various advantages. Read this document to gain more insights about laser technology for cutting and shaping the sheet metals. For more information visit https://www.form2000.com.au/capabilities/laser-cutting.php

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Sheetmetal</strong><br />

<strong>Form2000</strong><br />

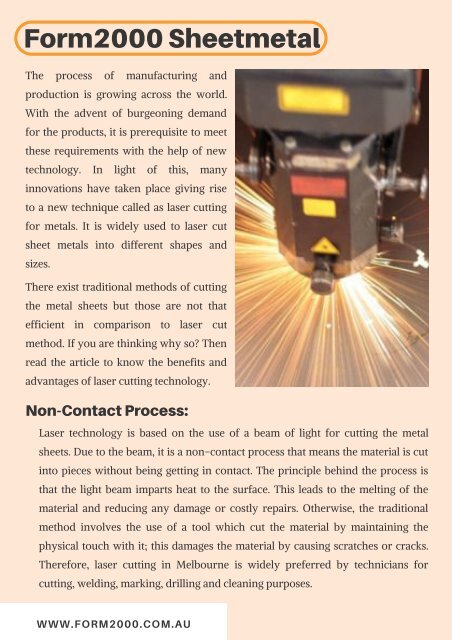

The process <strong>of</strong> manufacturing and<br />

production is growing across the world.<br />

With the advent <strong>of</strong> burgeoning demand<br />

for the products, it is prerequisite to meet<br />

these requirements with the help <strong>of</strong> new<br />

technology. In light <strong>of</strong> this, many<br />

innovations have taken place giving rise<br />

to a new technique called as laser cutting<br />

for metals. It is widely used to laser cut<br />

sheet metals into different shapes and<br />

sizes.<br />

There exist traditional methods <strong>of</strong> cutting<br />

the metal sheets but those are not that<br />

efficient in comparison to laser cut<br />

method. If you are thinking why so? Then<br />

read the article to know the benefits and<br />

advantages <strong>of</strong> laser cutting technology.<br />

Process:<br />

Non-Contact<br />

<strong>Laser</strong> technology is based on the use <strong>of</strong> a beam <strong>of</strong> light for cutting the metal<br />

sheets. Due to the beam, it is a non-contact process that means the material is cut<br />

into pieces without being getting in contact. The principle behind the process is<br />

that the light beam imparts heat to the surface. This leads to the melting <strong>of</strong> the<br />

material and reducing any damage or costly repairs. Otherwise, the traditional<br />

method involves the use <strong>of</strong> a tool which cut the material by maintaining the<br />

physical touch with it; this damages the material by causing scratches or cracks.<br />

Therefore, laser cutting in Melbourne is widely preferred by technicians for<br />

cutting, welding, marking, drilling and cleaning purposes.<br />

WWW.FORM2000.COM.AU