GM RAILING – Product Report

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>GM</strong> <strong>RAILING</strong> ®<br />

PRODUCT REPORT

TABLE OF CONTENTS<br />

Introduction P. 03<br />

<strong>GM</strong> Worlds of Colour P. 04<br />

Surface treatment & glass types P. 06<br />

<strong>GM</strong> <strong>RAILING</strong> ® Introduction P. 08<br />

<strong>GM</strong> <strong>RAILING</strong> ® Modular concept P. 10<br />

<strong>GM</strong> <strong>RAILING</strong> ® Do’s and Don’ts P. 12<br />

<strong>Product</strong> Overview <strong>–</strong> The Systems P. 14<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI SOLO P. 16<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE P. 18<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI PART P. 20<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI TOP P. 22<br />

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U P. 24<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE U P. 26<br />

<strong>GM</strong> <strong>RAILING</strong> ® PLAN P. 28<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT P. 30<br />

<strong>GM</strong> <strong>RAILING</strong> ® FRONT P. 32<br />

Detail data base P. 34<br />

Test certificates P. 36<br />

<strong>GM</strong> <strong>RAILING</strong> ® CONSTRUCTION GUARDRAIL P. 38<br />

<strong>GM</strong> <strong>RAILING</strong> ® ACCESSOIRES P. 40<br />

All from one source P. 42

GLAS MARTE<br />

COMPANY PROFILE<br />

Innovative development, competent advice, detailed planning<br />

and masterful execution <strong>–</strong> you will find all this united<br />

under the umbrella of Glas Marte.<br />

Founded in 1930, the company has successively expanded<br />

its knowledge of the versatile building material glass and today<br />

offers a wide range of products, from flat and insulating<br />

glass to a wide variety of surfaces and award-winning sliding<br />

and holding systems as well as DIBt-tested glass railings.<br />

Whether indoors or outdoors, in private or public buildings<br />

<strong>–</strong> the more complex the requirements, the more innovative<br />

and creative the concept, the more you are in good hands<br />

with Glas Marte.

4 | <strong>GM</strong> <strong>RAILING</strong> ® <strong>–</strong> <strong>GM</strong> WORLD OF COLOURS

<strong>GM</strong> WORLDS OF COLOUR<br />

EXPRESSIVE DESIGN<br />

Colour has an impact. A cool blue, a warm red or rather a<br />

fresh green <strong>–</strong> the choice of colour is of central importance<br />

in interior design. It essentially determines the atmosphere.<br />

Whether outside or inside, glass can be used to create<br />

permanent accents of colour. Quite discreet or powerfully<br />

luminous. Entire expanses, partial surfaces or with individual<br />

patterns. Glas Marte supplies hundreds of shades, applied<br />

by screen or roller printing or incorporated by way of<br />

coloured laminated glass films.<br />

Be inspired by the wide range of colours!<br />

<strong>GM</strong> WORLD OF COLOURS <strong>–</strong> <strong>GM</strong> <strong>RAILING</strong> ® | 5

SURFACE TREATMENT<br />

UNIQUE EFFECT<br />

Glass can be ultra-smooth But it doesn’t have to be. Glass Marte developed and<br />

refined various surface treatment options ranging from complex sandblasting to<br />

several types of printing to the production of to textured glass to the incorporation<br />

of the finest embroideries within the glass.<br />

When it comes to <strong>GM</strong> ICE-H ® , for example, glass material is detached from<br />

the surface, which leaves an interesting, uniquely broken surface structure with<br />

a cool, vibrant appearance. Translucent and reflective at the same time, the<br />

<strong>GM</strong> LAMIMARTEX ® Collection, where textile and glass merge into one.<br />

<strong>GM</strong> ICE-H ®<br />

6 | <strong>GM</strong> <strong>RAILING</strong> ® <strong>–</strong> SURFACE TREATMENT

GLASS TYPES<br />

SAFETY TESTED<br />

Place and purpose determine the type of glass used. As<br />

a processor and manufacturer, Glas Marte offers a wide<br />

range of glass types for this purpose: tempered, laminated<br />

and insulating glass from our own, controlled manufacturing<br />

as well as mirrors, ornamental glass, scratch resistant or<br />

shower glass to name but a few.<br />

As a customer you benefit not only from our many years of<br />

experience but also from the short distances between competent<br />

advice, ultra-modern production and proper delivery,<br />

which Glas Marte guarantees as a full-range supplier.<br />

<strong>GM</strong> LAMIMARTEX ®<br />

<strong>GM</strong> SATINATO ®<br />

<strong>GM</strong> SATINATO ® FLOWER<br />

<strong>GM</strong> TEMPERED GLASS COLORMART ®<br />

<strong>GM</strong> SATINATO ® STRAIGHT<br />

GLAS TYPES <strong>–</strong> <strong>GM</strong> <strong>RAILING</strong> ® | 7

Additional Information<br />

on <strong>GM</strong> <strong>RAILING</strong> ®<br />

<strong>GM</strong> <strong>RAILING</strong> ®<br />

THE MECHANICALLY PERFECT MODULAR SOLUTIONS<br />

As a building material and design element, glass has long been a solid architectural fixture. However,<br />

glass balustrades are still a challenge for every planner, architect or structural engineer <strong>–</strong> not to<br />

mention their construction and assembly. <strong>GM</strong> <strong>RAILING</strong> ® has developed a perfect technical modular<br />

solution for these special requirements.<br />

<strong>GM</strong> <strong>RAILING</strong> ® impresses with its versatile application possibilities. Based on five basic systems <strong>–</strong><br />

UNI, LEVEL U, MASSIVE U, PLAN, BENT and FRONT — we can provide a variety of solutions to fulfil<br />

nearly all requirements. <strong>GM</strong> Engineering will be pleased to assist you in the implementation of more<br />

sophisticated special solutions.<br />

THE MODULAR CONCEPT<br />

<strong>GM</strong> <strong>RAILING</strong> ® glass balustrades consist of a prefabricated glass construction module (glass + profile<br />

are firmly connected to each other at the factory and optimally supported) and a substructure perfectly<br />

matched to the construction.<br />

Assembly can be ideally integrated into a construction schedule due to the delivery of the glass<br />

construction module (glass + profile in a prefab module). The installation of the glass itself usually only<br />

takes place during the course of the completion work. The glass and all visible surfaces are therefore<br />

optimally protected against soiling and damage caused by the construction work in the final phase of<br />

the project.<br />

Substructure<br />

Prefab glass construction<br />

module<br />

+ =<br />

<strong>GM</strong> <strong>RAILING</strong> ®<br />

Balustrades

ADVANTAGES OF THE <strong>GM</strong> <strong>RAILING</strong> ® SERIES<br />

»»<br />

Modular concept reduces construction and planning<br />

efforts<br />

»»<br />

Optimum cavity-free glass storage<br />

»»<br />

Even bedding without high stress peaks<br />

»»<br />

Infinitely adjustable<br />

»»<br />

Various construction variants possible(steel, wood<br />

and solid construction)<br />

»»<br />

Competent and comprehensive support and technical<br />

elaboration via <strong>GM</strong> Engineering<br />

»»<br />

Safety tested (test certificates available)<br />

»»<br />

All verification according to DIN 18008-4 available.<br />

»»<br />

Detail database/hundreds of design options<br />

<strong>GM</strong> <strong>RAILING</strong> ® | 9

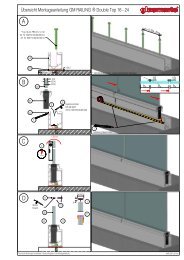

ASSEMBLY IN 2 STEPS<br />

EASY AND FAST<br />

<strong>GM</strong> <strong>RAILING</strong> ® balustrade systems allow for linear bearings without the need for<br />

vertical columns due to prefabricated glass construction modules in conjunction<br />

with a substructure profile and a continuous handrail.<br />

The prefabricated glass construction modules are mounted in the substructure<br />

profiles, which are to be installed on-site, and screwed together using cylinder<br />

screws or special spacers. This screw connection allows for tolerance compensation<br />

of the vertical position at rail height. Due to the fixing in the mounting rail,<br />

no glass drillings are necessary. This reduces planning and assembly effort as<br />

well as costs. Systematisation can generate benefits across all areas.<br />

EXPLAINED STEP BY STEP<br />

Simple<br />

mounting<br />

Infinitely adjustable<br />

+ =<br />

Uniform glass bearing<br />

without stress peaks<br />

10 | <strong>GM</strong> <strong>RAILING</strong> ® <strong>–</strong> MODULAR CONCEPT

STANDARD-COMPLIANT DESIGN<br />

OF GLASS BALUSTRADES<br />

<br />

DO’S<br />

<br />

DON’TS<br />

PRESSURE-FREE INSTALLATION<br />

Low constraint storage<br />

DIN 18008-1 <strong>–</strong> 10.1.3<br />

ÖN B 3716-1 <strong>–</strong> 6.2<br />

SIGAB 002 <strong>–</strong> 5.3<br />

Forced strain due to installation<br />

Wedges must not be used<br />

(local stresses)<br />

UNCHANGEABLE<br />

POSITION STABILITY<br />

Position stability through destabilising<br />

effects<br />

EN 1990<br />

CHANGE THROUGH USE<br />

Non rectifiable serviceability limit state due to<br />

e.g. dirt (gravel ...)<br />

Indirect effects from ice, snow and wetness influence<br />

storage conditions<br />

Environmental influences with effect on the<br />

durability of the supporting structure<br />

UNEXPECTED STRAINS<br />

Avoidance of influences from the substructure<br />

on the glass railing, e.g. deformations<br />

DIN 18008-1 <strong>–</strong> 3.1.1 and 7.1.5 I<br />

ÖN B 3716-1 <strong>–</strong> 1<br />

Substructure may negatively influence<br />

the glass statics<br />

Our interpretation of standards and technical guidelines; This list does not claim to be exhaustive.<br />

12 | <strong>GM</strong> <strong>RAILING</strong> ® <strong>–</strong> DO‘S AND DON‘TS

PRODUCT OVERVIEW<br />

<strong>GM</strong> <strong>RAILING</strong> ® <strong>–</strong> THE SYSTEMS<br />

UNIVERSAL from Page 16<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI<br />

THE UNIVERSAL SOLUTION<br />

The <strong>GM</strong> <strong>RAILING</strong> ® UNI system can be easily integrated into a wide variety<br />

of constructions thanks to the consistent modular structure of the various<br />

variants, giving planners a unique freedom of design.<br />

IN THE<br />

GROUND<br />

from Page 24<br />

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U<br />

FOR INSTALLATION WITH EXPOSED CONCRETE<br />

The <strong>GM</strong> <strong>RAILING</strong> ® LEVEL U system is designed for applications in which the<br />

mounting unit for the glass railing is recessed in the floor surface <strong>–</strong> concrete.<br />

Only the relevant base and protruding glass itself are to be seen.<br />

LATERAL/<br />

ON TOP<br />

from Page 26<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE U<br />

FOR INDIVIDUAL PLANNING DETAILS<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE U is a glass railing designed for installations where<br />

the construction is no longer accessible from the side. The profile can be<br />

attached to a solid structure from above as well as from the side.<br />

FLUSH-<br />

MOUNTED<br />

from Page 28<br />

<strong>GM</strong> <strong>RAILING</strong> ® PLAN<br />

FOR HIGHEST ARCHITECTURAL NEEDS<br />

The <strong>GM</strong> <strong>RAILING</strong> ® PLAN fastening concept is a railing fastening that uses<br />

clear and direct architectural vocabulary. It impresses due to its flush-mounting<br />

and is refined in its details. Glass is the only thing visible, without fail.<br />

BENT from Page 30<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT<br />

FOR BENT GLASS BALUSTRADES<br />

The greatest advantage of the <strong>GM</strong> <strong>RAILING</strong> ® BENT system is the systematisation<br />

of fastening and storage. The glass base, which is manufactured to<br />

the highest quality and remains consistent over all radii and bending shapes,<br />

permits systematic statics.<br />

ATTIKA<br />

INSIDE<br />

from Page 32<br />

<strong>GM</strong> <strong>RAILING</strong> ® FRONT<br />

FOR TRANSPARENT RAISING OF THE BALUSTRADE<br />

<strong>GM</strong> <strong>RAILING</strong> ® FRONT is designed for lateral mounting on the side facing<br />

the viewer, in a solid brick foundation or low wall above the cornice of a<br />

classical façade.<br />

14 | <strong>GM</strong> <strong>RAILING</strong> ®

<strong>GM</strong> <strong>RAILING</strong> ® UNI SOLO<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI PART<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI TOP<br />

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE UT<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE US<br />

<strong>GM</strong> <strong>RAILING</strong> ® PLAN 1<br />

<strong>GM</strong> <strong>RAILING</strong> ® PLAN 2<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT TOP<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT SIDE<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT MASSIVE TOP<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT MASSIVE SIDE<br />

<strong>GM</strong> <strong>RAILING</strong> ® FRONT AIO<br />

<strong>GM</strong> <strong>RAILING</strong> ® FRONT AIT<br />

<strong>GM</strong> <strong>RAILING</strong> ® | 15

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® UNI SOLO<br />

2<br />

+/- 20 mm<br />

SPECIAL ADVANTAGES<br />

h 3 = 6<br />

26<br />

46<br />

»»<br />

Suspension profile is mounted<br />

onto on-site steel construction<br />

25.5<br />

33<br />

gb<br />

»»<br />

Cost-effective application with<br />

many different solutions<br />

»»<br />

Vertical position infinitely adjustable<br />

»»<br />

AbP P-2018-3064<br />

htot = 1085 - 1285<br />

h 2 =185 h 1 = 900 - 1100<br />

A<br />

ca<br />

29<br />

90<br />

61<br />

V<br />

ca<br />

10<br />

12<br />

br<br />

scbs<br />

bb<br />

hb<br />

150<br />

ffl<br />

aj<br />

hr<br />

h-of = 35<br />

d 1 = 69 ± 3<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® UNI SOLO 20 | 2. <strong>GM</strong> <strong>RAILING</strong> ® UNI SOLO 30<br />

1<br />

+/- 20 mm<br />

h 3 = 6<br />

8<br />

24<br />

29<br />

hr<br />

gb<br />

17.5<br />

21.5<br />

25.5<br />

htot = 1060 - 1460<br />

h 1 = 900 - 1300<br />

A<br />

77<br />

V<br />

hb<br />

29<br />

48<br />

ffl<br />

ca<br />

12<br />

ad<br />

h 2 = 162<br />

cpc<br />

10 8<br />

12<br />

br<br />

dte min. 60<br />

134<br />

af<br />

aj<br />

scbs<br />

h-of = 39<br />

d 1 = 68 ± 3

<strong>GM</strong> <strong>RAILING</strong> ® UNI SOLO<br />

SUITED FOR STEEL SUBSTRUCTURE<br />

Due to the use of a simple structural steel as substructure, UNI SOLO is a<br />

versatile and extremely adaptable series of the glass railing system<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI.<br />

The innumerable possibilities for substructure design facilitate the planning and<br />

execution of the <strong>GM</strong> <strong>RAILING</strong> ® glass railing system, especially for renovations<br />

and conversions. The UNI SOLO series is also optimally compatible with the<br />

design requirements of the various construction types.<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI SOLO | 17

8<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE<br />

2<br />

+/- 20 mm<br />

SPECIAL ADVANTAGES<br />

h³ = 4<br />

24<br />

29<br />

hr<br />

»»<br />

Low construction depth, particularly<br />

effective even in staircase<br />

and ramp areas<br />

»»<br />

Versatile fastening possibilities<br />

htot = 1060 - 1260<br />

h 1 = 900 - 1100<br />

A<br />

17.5<br />

21.5<br />

25.5<br />

gb<br />

V<br />

hb<br />

»»<br />

Vertical position infinitely<br />

adjustable<br />

»»<br />

AbP P-2018-3064<br />

h 2 = 162<br />

cpc<br />

70<br />

26 44<br />

ffl<br />

ca<br />

br<br />

12<br />

dte min. 57<br />

af<br />

uc<br />

aj<br />

bb<br />

h-of = 46<br />

d 1 = 73 ± 3<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE 20 | 2. <strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE 16<br />

1<br />

+/- 20 mm<br />

h 3 = 6<br />

8<br />

24<br />

29<br />

hr<br />

gb<br />

17.5<br />

21.5<br />

25.5<br />

htot = 1060 - 1460<br />

h 1 = 900 - 1300<br />

A<br />

77<br />

V<br />

hb<br />

29<br />

48<br />

ffl<br />

ca<br />

h 2 = 162<br />

cpc<br />

br<br />

dte min. 57<br />

af<br />

uc<br />

aj<br />

h-of = 50<br />

d 1 = 79 ± 3

<strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE<br />

FOR LATERAL ASSEMBLY<br />

The substructure of <strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE is specially designed to be<br />

laterally attached to the supporting structure.<br />

Particularly for designs involving ceilings, ramps and stairs, the shallow<br />

construction depth allows for well thought-out detailed planning that takes into<br />

account the often limited space available in the staircase area. One central<br />

advantage of the system is the easy fastening to very flat base superstructures<br />

on the glass railing. <strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE thus makes it possible to implement<br />

an extremely wide range of detailed solutions, particularly indoors.<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI SIDE | 19

h<br />

8<br />

8<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® UNI PART<br />

2<br />

+/- 20 mm<br />

SPECIAL ADVANTAGES<br />

h³ = 4<br />

24<br />

29<br />

hr<br />

»»<br />

For mounting at the component<br />

edge<br />

17.5<br />

21.5<br />

25.5<br />

gb<br />

»»<br />

Penetration-resistant roof sealing<br />

with excellent thermal insulation<br />

»»<br />

Construction can be used irrespective<br />

of the building situation<br />

htot = 1060 - 1260<br />

1 = 900 - 1100<br />

A<br />

cpc<br />

26<br />

70<br />

44<br />

V<br />

ca<br />

hb<br />

82<br />

ffl<br />

»»<br />

Vertical position infinitely adjustable<br />

»»<br />

AbP P-2018-3064<br />

h 2 = 162<br />

af<br />

aj<br />

br<br />

uc<br />

dte 82<br />

162<br />

h-of = 41<br />

d 1 = 68 ± 3<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® UNI PART 20 | 2. <strong>GM</strong> <strong>RAILING</strong> ® UNI PART 16<br />

1<br />

+/- 20 mm<br />

h³ = 4<br />

8<br />

24<br />

29<br />

hr<br />

gb<br />

17.5<br />

21.5<br />

25.5<br />

htot = 1060 - 1260<br />

h 1 = 900 - 1100<br />

A<br />

29<br />

77<br />

48<br />

V<br />

hb<br />

8<br />

ffl<br />

ca<br />

cpc<br />

h 2 = 162<br />

82<br />

br<br />

uc<br />

af<br />

aj<br />

dte 80<br />

160<br />

h-of = 45<br />

d 1 = 74 ± 3

<strong>GM</strong> <strong>RAILING</strong> ® UNI PART<br />

FOR SEALING AND THERMAL INSULATION SYSTEMS<br />

The <strong>GM</strong> <strong>RAILING</strong> ® UNI PART series is designed to be mounted on the component<br />

edge. <strong>GM</strong> <strong>RAILING</strong> ® UNI PART is the excellent solution for highly<br />

insulated, energy-efficient areas of the building envelope such as roof terraces<br />

or balconies above living spaces.<br />

Due to the position on the edge of the component, the insulated components<br />

can be combined with the <strong>GM</strong> <strong>RAILING</strong> ® UNI PART glass railing in an architecturally<br />

appealing manner while reducing the disturbance to the heat-insulating<br />

building envelope to a minimum.<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI PART | 21

h<br />

8<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® UNI TOP<br />

2<br />

+/- 20 mm<br />

SPECIAL ADVANTAGES<br />

h³ = 4<br />

24<br />

29<br />

hr<br />

»»<br />

The substructure profile is both<br />

the border for floor construction<br />

or screed.<br />

»»<br />

An integrally formed flange can<br />

be used as a support surface<br />

for a raised floor.<br />

htot = 1060 - 1260<br />

h 1 = 900 - 1100<br />

A<br />

cpc<br />

26<br />

17.5<br />

21.5<br />

25.5<br />

70<br />

44<br />

gb<br />

V<br />

hb<br />

ffl<br />

»»<br />

Vertical position infinitely adjustable<br />

»»<br />

AbP P-2018-3064<br />

h 2 = 162<br />

af<br />

aj<br />

h-of = 26<br />

dte ≥ 76<br />

br<br />

uc<br />

bb<br />

196± 3<br />

160 (min. 157)<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® UNI TOP 20 | 2. <strong>GM</strong> <strong>RAILING</strong> ® UNI TOP 16<br />

1<br />

+/- 20 mm<br />

h³ = 4<br />

8<br />

24<br />

29<br />

hr<br />

gb<br />

17.5<br />

21.5<br />

25.5<br />

htot = 1060 - 1260<br />

1 = 900 - 1100<br />

A<br />

29<br />

77<br />

47<br />

V<br />

hb<br />

ffl<br />

cpc<br />

br<br />

h 2 = 162<br />

uc<br />

165<br />

af<br />

aj<br />

bb<br />

h-of=29<br />

dte ≥ 76<br />

202± 3

<strong>GM</strong> <strong>RAILING</strong> ® UNI TOP<br />

FOR MOUNTING ON CEILINGS WITH FLOOR<br />

STRUCTURE<br />

The substructure of <strong>GM</strong> <strong>RAILING</strong> ® UNI TOP is specially designed to be<br />

attached to the supporting structure from above.<br />

The cross section of the substructure allows a simple connection of the sealing<br />

and insulation levels to the glass railing due to the curved flank. The technical<br />

requirements for the waterproofing of terrace surfaces and other walkable<br />

external surfaces can thus be optimally planned and executed.<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI TOP | 23

50<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® LEVEL U<br />

2<br />

SPECIAL ADVANTAGES<br />

»»<br />

Mounting construction not visible<br />

d=74<br />

ffl<br />

»»<br />

Assembly and adjustment of the<br />

glass construction module from<br />

above<br />

146<br />

149<br />

»»<br />

Aesthetically extremely appealing,<br />

lightweight appearance<br />

sr<br />

dbs<br />

»»<br />

Exact concrete groove defines<br />

geometry<br />

»»<br />

AbP A-15-014<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® LEVEL U | 2. <strong>GM</strong> <strong>RAILING</strong> ® LEVEL U FORMWORK PROFILE<br />

1<br />

+/- 20 mm<br />

h3= 6<br />

8<br />

24<br />

29<br />

hr<br />

gb<br />

17.5<br />

21.5<br />

25.5<br />

htot = 1044 - 1444<br />

h 1 = 900 - 1300<br />

A<br />

50<br />

74<br />

37 ±3<br />

50<br />

V<br />

ca<br />

hb<br />

ffl<br />

aj<br />

aw<br />

h 2 = 144<br />

bt<br />

sr<br />

dbs

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U<br />

FOR INSTALLATION WITH EXPOSED CONCRETE<br />

The <strong>GM</strong> <strong>RAILING</strong> ® LEVEL U system is designed for applications in which the<br />

mounting unit for the glass railing is recessed in the floor surface — concrete.<br />

Only the relevant base and protruding glass itself are to be seen.<br />

The fall protection glazing protrudes from a groove in the floor. This is<br />

achieved by means of a special formwork profile, which has to be assembled<br />

before concreting. The constructive "inner workings" are only introduced after<br />

the formwork profile has been removed.<br />

For the <strong>GM</strong> <strong>RAILING</strong> ® LEVEL U system, the profile is removed from the concrete<br />

after the curing process. This procedure defines a clear geometry for the<br />

glass assembly.<br />

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U | 25

8<br />

h-of = 39<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® MASSIVE U<br />

2<br />

+/- 20 mm<br />

SPECIAL ADVANTAGES<br />

h³ = 4<br />

24<br />

29<br />

hr<br />

»»<br />

Suitable for a wide range of<br />

installation situations<br />

17.5<br />

21.5<br />

25.5<br />

gb<br />

»»<br />

Assembly and adjustment of the<br />

glass construction module from<br />

above<br />

htot = 1056 - 1456<br />

h 1 = 900 - 1300<br />

A<br />

40<br />

80<br />

40<br />

V<br />

ca<br />

aj<br />

hb<br />

ffl<br />

»»<br />

Clear geometrical shape<br />

h 2 = 156<br />

bt<br />

dte ≥ 50<br />

»»<br />

AbP A-15-014<br />

uc<br />

bb<br />

d 1 90<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® MASSIVE UT | 2. <strong>GM</strong> <strong>RAILING</strong> ® MASSIVE US<br />

1<br />

+/- 20 mm<br />

h 3 = 6<br />

8<br />

24<br />

29<br />

hr<br />

gb<br />

17.5<br />

21.5<br />

25.5<br />

htot = 1052 - 1452<br />

h 2 = 152 h1 = 900 - 1300<br />

A<br />

40<br />

80<br />

40<br />

V<br />

ca<br />

aj<br />

uc<br />

bt<br />

hb<br />

bb<br />

ffl<br />

d = 90<br />

dte ≥ 105

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE U<br />

FOR INDIVIDUAL PLANNING DETAILS<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE U is a railing fastening concept for glass railing<br />

according to DIN 18008-4 for installations where the construction is no<br />

longer accessible from the side. The profile can be attached to a solid<br />

structure from above as well as from the side.<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE is the structural profile for all scenarios. It is multifunctional<br />

and therefore also very popular for private use.<br />

The U series is characterised by a clear geometric shape.<br />

<strong>GM</strong> <strong>RAILING</strong> ® MASSIVE U | 27

h<br />

8<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® PLAN<br />

2<br />

+/- 20 mm<br />

SPECIAL ADVANTAGES<br />

»»<br />

Clear architectural language<br />

»»<br />

Only the whole glass is visible<br />

without substructure profiles<br />

»»<br />

Can also be used for very high,<br />

suspended ceiling constructions.<br />

h tot = 1060 - 1260 h2 = 1 = 157 900 - 1100<br />

h³ = 4<br />

A<br />

24<br />

29<br />

21.5<br />

25.5<br />

hr<br />

gb<br />

V<br />

br<br />

uc<br />

bb<br />

aj<br />

hb<br />

dte ≥ 58<br />

ffl<br />

»»<br />

Flush connections possible<br />

h-of = 39<br />

d 1 = 60 ± 3<br />

Typ L<br />

Typ V<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® PLAN 1 | 2. <strong>GM</strong> <strong>RAILING</strong> ® PLAN 2<br />

1<br />

+/- 20 mm<br />

htot = 1060 - 1260<br />

h 1 = 900 - 1100 8<br />

A<br />

h³ = 4<br />

29<br />

21.5<br />

25.5<br />

h-of = 39<br />

hr<br />

gb<br />

V<br />

hb<br />

ffl<br />

ca<br />

uc<br />

bb<br />

dte ≥ 58<br />

h 2 = 160<br />

br<br />

aj<br />

d 1 = 61 ± 3

<strong>GM</strong> <strong>RAILING</strong> ® PLAN<br />

FOR HIGHEST ARCHITECTURAL NEEDS<br />

The <strong>GM</strong> <strong>RAILING</strong> ® PLAN fastening concept is a railing fastening that uses<br />

clear and direct architectural vocabulary. It impresses due to its flush-mounting<br />

and is refined in its details.<br />

Glass is the only thing visible, without fail.<br />

What starts as glazing preventing falls at the railing merges flush with the construction<br />

at the contact point on the floor. The exterior glass area exceeds the<br />

floor and ceiling constructions and only ends at its intersection with the ceiling<br />

lying below. The mounts themselves cannot be seen, there are no protruding<br />

elements on the outside of the glass and there is no change in materials. The<br />

<strong>GM</strong> <strong>RAILING</strong> ® PLAN system is our premium product<br />

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U | 29

8<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® BENT<br />

2<br />

+/- 20 mm<br />

SPECIAL ADVANTAGES<br />

h³=4<br />

24<br />

29<br />

hr<br />

gb<br />

»»<br />

Simple mountable substructure.<br />

17.5<br />

21.5<br />

25.5<br />

»»<br />

Only the glass is bent, construction<br />

and bearing profiles<br />

adapt to the glass and enable<br />

optimum glass bedding.<br />

»»<br />

Convex, concave, regular and<br />

free bending shapes possible<br />

htot = 1050 - 1250<br />

h 2 = 150 h1 = 900 - 1100<br />

A<br />

ca<br />

cp<br />

cop<br />

aj<br />

40<br />

80<br />

40<br />

V<br />

rg<br />

br<br />

uc<br />

hb<br />

dte ≥ 55<br />

ffl<br />

»»<br />

Excellent tolerance compensation<br />

d 1 = 86<br />

h-of = 40<br />

»»<br />

AbP A-12-013/AbP A-13-021<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® BENT MT | 2. <strong>GM</strong> <strong>RAILING</strong> ® BENT MS<br />

1<br />

+/- 20 mm<br />

h³=4<br />

8<br />

29<br />

hr<br />

gb<br />

21.5<br />

25.5<br />

htot = 1052 - 1252<br />

h 2 = 152 h 1 = 900 - 1100<br />

A<br />

ca<br />

cp<br />

cop<br />

40<br />

80<br />

40<br />

V<br />

rg<br />

br<br />

uc<br />

ucb<br />

bb<br />

hb<br />

152 (min. 150)<br />

ffl<br />

aj<br />

46<br />

80 145<br />

dte ≥ 120<br />

dte ≥ 200

<strong>GM</strong> <strong>RAILING</strong> ® BENT<br />

FOR BENT GLASS BALUSTRADES<br />

Glass balustrades for modern architecture. The greatest advantage of the<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT system is the systematisation of fastening and storage.<br />

The glass base, which is manufactured to the highest quality and remains<br />

consistent over all radii and bending shapes, permits systematic statics and<br />

therefore also allows for a substantially simplified certification procedure.<br />

Technical implementation solutions are developed to the highest level and<br />

optimally adapted to customer-specific requirements and situations. Depending<br />

on the strength of the curvature <strong>–</strong> bending radius <strong>–</strong> the static system of<br />

one-sided glass clamping becomes increasingly complex with a multitude of<br />

different stress situations and functional states.<br />

<strong>GM</strong> <strong>RAILING</strong> ® BENT has solved this task flexibly, safely and ingeniously<br />

simply.<br />

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U | 31

8<br />

HUD<br />

+/- 20 mm<br />

More information<br />

on <strong>GM</strong> <strong>RAILING</strong> ® FRONT<br />

SPECIAL ADVANTAGES<br />

2<br />

ld<br />

26<br />

19<br />

23<br />

28<br />

34<br />

hr<br />

h 3 = 6<br />

»»<br />

Especially for low walls above<br />

the cornice of a classical façade<br />

and brick benches<br />

»»<br />

Only the whole glass is visible<br />

without substructure profiles<br />

»»<br />

AbP A-15-001/AbP A-13-017<br />

ws<br />

dte ≥ 40<br />

A<br />

v-of = 36<br />

13.5<br />

15<br />

17.5<br />

21.5<br />

gb<br />

V<br />

uc<br />

br<br />

bb<br />

aj<br />

h 2 ≥ 300 h1 max = 1000<br />

htot = 1300<br />

hb<br />

bb<br />

bt<br />

32<br />

d 1 = 51<br />

h-of = 40<br />

ffl<br />

1. <strong>GM</strong> <strong>RAILING</strong> ® FRONT AI0 | 2. <strong>GM</strong> <strong>RAILING</strong> ® FRONT AIT<br />

1<br />

+/- 20 mm<br />

23<br />

28<br />

34<br />

h 3 = 6<br />

ld<br />

26<br />

hr<br />

gb<br />

13.5<br />

15<br />

17.5<br />

21.5<br />

A<br />

V<br />

h 1 max = 900<br />

htot = 1040<br />

hb<br />

ws<br />

v-of = 36<br />

uc<br />

dte ≥ 40<br />

br<br />

h2 = 140<br />

bb<br />

aj<br />

32<br />

d = 53<br />

d 1 = 56<br />

h-of = 40<br />

ffl

<strong>GM</strong> <strong>RAILING</strong> ® FRONT<br />

FOR TRANSPARENT RAISING OF THE BALUSTRADE<br />

<strong>GM</strong> <strong>RAILING</strong> ® FRONT is designed for lateral mounting on the side facing<br />

the viewer, in a solid brick foundation or low wall above the cornice of a<br />

classical façade.<br />

The <strong>GM</strong> <strong>RAILING</strong> ® FRONT fixing concept is an elegant glass railing which<br />

creates transparent, weightless-appearing raised balustrades, technically<br />

perfected and of the highest quality. <strong>GM</strong> <strong>RAILING</strong> ® FRONT functions as a fall<br />

protection system and is an independent design element, which gives every<br />

building structure a touch of extravagance.<br />

<strong>GM</strong> <strong>RAILING</strong> ® LEVEL U | 33

DETAIL DATA BASE<br />

CUMULATIVE KNOW-HOW<br />

The many years of experience of our versed glass construction technicians is<br />

the basis for object-related detail solutions which have contributed significantly<br />

to the successful realisation of a wide variety of properties, from detached<br />

houses to impressive corporate headquarters. You too can benefit from this<br />

wealth of experience and learn more connection details and design options of<br />

<strong>GM</strong> <strong>RAILING</strong> ® systems via our extensive <strong>GM</strong> <strong>RAILING</strong> ® database.<br />

Do you need individual support for special design tasks? Our specialists will be<br />

happy to assist you with the creation of the required special solutions.<br />

In cooperation with our own development department, we leave no stone<br />

unturned when ensuring your planning task is solved to your satisfaction, taking<br />

technical and economic aspects into account.<br />

We passionately strive to live up to our position as a spearhead in terms of<br />

technological prowess and expertise.<br />

DETAILS AVAILABLE AS DWG, DXF OR PDF FILE AT:<br />

EPAPER.GLASMARTE.AT<br />

34 | <strong>GM</strong> <strong>RAILING</strong> ®

NUMEROUS ADDITIONAL<br />

DETAILS CAN BE EASILY<br />

DOWNLOADED AT<br />

EPAPER.GLASMARTE.AT

<strong>GM</strong> <strong>RAILING</strong> ® TEST CERTIFICATES<br />

PATENTED, TESTED 100-FOLD, INTERNATIONALLY ACCEPTED<br />

According to DIN 18008-4 - 6.1, the effects of damage to any parapet element (including the failure<br />

of end plates) must be proven. In case of failure of a parapet element, especially in the interaction<br />

of handrail and broken glass, this can best be demonstrated by experiments.<br />

Depending on the glass choice (VSG from 2x tempered safety glass or VSG 2x TVG or VSG 2x float<br />

glass) and film thickness, the results of breakage tests may vary drastically. The broken glass partially<br />

has a residual stability or residual supporting properties. Depending on the type of glass, this can<br />

have a positive or negative impact on the overall system. To date, no method is known to us, as to<br />

how the residual strength of broken glass can be conclusively demonstrated mathematically. For this<br />

reason, <strong>GM</strong> <strong>RAILING</strong> has performed hundreds of glass breakage tests with original components up to<br />

a single length of 4 m.<br />

In addition, we have static verifications for all series and a very large pool of permits for special<br />

situations or requirements. <strong>GM</strong> <strong>RAILING</strong> ® is also able to take your individual requirements into account<br />

thanks to a certified calculation program.<br />

LAMINATED GLASS/<br />

FLOAT<br />

LAMINATED/TVG<br />

LAMINATED/<br />

TEMPERED<br />

TESTING LAB<br />

<strong>GM</strong> <strong>RAILING</strong> ® GLASS BALUSTRADES HAVE BEEN SUBMITTED TO COUNTLESS TESTS.<br />

Fracture resistance, stability, load-bearing capacity, residual stability are just a few of the many parameters<br />

that we constantly monitor and test in our test laboratory. We are able to do so, in addition to a<br />

high level of expertise, due to the appropriate equipment of various testing facilities.<br />

In addition to the classic pendulum impact test, residual stability, fracture resistance, reaction to tensile<br />

and compressive loads and stability of brackets and suspension profiles are tested, recorded and<br />

logged with DKD-calibrated testing machines.<br />

<strong>GM</strong> <strong>RAILING</strong> ® is subjected to regular material and component tests by internal and external test centres.<br />

GENERAL TEST CERTIFICATES ISSUED BY THE BUILDING AUTHORITIES<br />

<strong>GM</strong> <strong>RAILING</strong> ®<br />

<strong>GM</strong> <strong>RAILING</strong> ® SERIES<br />

TEST CERTIFICATE NO.<br />

OF THE RESPECTIVE TEST INSTITUTE<br />

TEST TYPE<br />

UNI AbP P-2018-3064 Shock-like action <strong>–</strong> pendulum impact<br />

MASSIVE/LEVEL AbP A-15-014 Shock-like action <strong>–</strong> pendulum impact<br />

FRONT AIO<br />

FRONT AIT<br />

BENT (VSG from TVG or ESG)<br />

BENT (VSG from Float)<br />

AbP A-15-001<br />

AbP A-13-017<br />

AbP A-12-013<br />

AbP A-13-021<br />

Shock-like action <strong>–</strong> pendulum impact<br />

Shock-like action <strong>–</strong> pendulum impact<br />

Shock-like action <strong>–</strong> pendulum impact<br />

Shock-like action <strong>–</strong> pendulum impact<br />

36 | <strong>GM</strong> <strong>RAILING</strong> ®

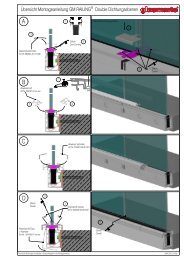

<strong>GM</strong> <strong>RAILING</strong> ® CONSTRUCTION GUARD RAIL<br />

COMPREHENSIVE RANGE<br />

FOR ALL SYSTEMS<br />

Glas Marte has developed a special construction guardrail for all <strong>GM</strong> <strong>RAILING</strong> ®<br />

systems for the period between substructure and glass assembly. By using a<br />

temporary building solution, all dangerous work in the fall area is significantly<br />

reduced when installing glass to prevent falls.<br />

The construction handrail is delivered to the construction site together. Over the<br />

course of assembling the glass modules, the auxiliary railing is dismantled and<br />

taken back by <strong>GM</strong> <strong>RAILING</strong> ® .<br />

A late glass module assembly is the best protection against damage during the<br />

construction period. This also prevents the glass railings from needing to be<br />

cleaned again.<br />

Overview of the most important features<br />

»»<br />

Substructure is assembled<br />

»»<br />

Construction auxiliary railing is hooked in and screwed in place<br />

»»<br />

All other trades can be completed in the meantime<br />

»»<br />

Construction guardrail is dismantled<br />

»»<br />

Glass railing is inserted<br />

38 | <strong>GM</strong> <strong>RAILING</strong> ®

DOWNLOAD ORDER<br />

FORM AT<br />

EPAPER.GLASMARTE.AT

8<br />

<strong>GM</strong> <strong>RAILING</strong> ® ACCESSORIES<br />

<strong>GM</strong> <strong>RAILING</strong> ® also offers additional products such as handrails and cover profiles in a wide range<br />

of designs and materials. Our development team is also happy to design individual special solutions.<br />

HANDRAILS<br />

<strong>GM</strong> <strong>RAILING</strong> ® offers a wide range of handrail variants. In addition to ground or polished stainless<br />

steel profiles we also offer wooden sheathing in various shapes and types of wood. Corner connections<br />

ensure exact aligning.<br />

As outlined in DIN 18008-4 - 6.1 <strong>–</strong> special proofs for category B glass parapets, <strong>GM</strong> <strong>RAILING</strong> ®<br />

handrails are able to transfer the rail loads to neighbouring elements, end posts or anchoring to the<br />

building in the event of complete failure of a parapet element.<br />

<strong>Product</strong> benefits:<br />

»»<br />

All verification according to DIN 18008-4 available.<br />

»»<br />

Due to the optimum glass clamping in the lower area, the handrail is mounted on the upper glass<br />

edge without having to align it.<br />

22<br />

18/20/24<br />

STAINLESS STEEL<br />

Available in Extralight,<br />

Light and Solid<br />

versions for all glass<br />

thicknesses<br />

WOOD<br />

For all glass thicknesses<br />

available in: Maple,<br />

birch, beech, oak,<br />

cherry, larch and nut<br />

(others on request)<br />

GLAS<br />

Glass edge protection<br />

"GLASS STRIPE" made<br />

of drawn transparent<br />

borosilicate glass,<br />

bonded in grey and<br />

black<br />

HANDRAIL<br />

SUPERIOR<br />

Can be used in<br />

combination with all<br />

glass thicknesses and<br />

series<br />

COVERING PROFILES<br />

<strong>GM</strong> <strong>RAILING</strong> ® cover profiles guarantee a visually appealing finished design. There are no limits to<br />

the design. The covers are available as standard as aluminium clip profiles with a height of 160 to<br />

280 mm in aluminium or stainless steel as edge profiles. Special solutions such as gypsum plasterboards<br />

or mirrors are also available on request.<br />

An inner metal edge has also been constructed at the transition to the floor covering in order to protect<br />

the floor from excessive moisture during wet cleaning.<br />

<strong>Product</strong> benefits:<br />

»»<br />

Simple mounting and dismantling of system components<br />

»»<br />

Screw fastenings not visible<br />

»»<br />

Numerous design advantages even when servicing is required<br />

40 | <strong>GM</strong> <strong>RAILING</strong> ®

<strong>GM</strong> <strong>RAILING</strong> ®<br />

ALL FROM ONE SOURCE<br />

1. Personal consultation| Order<br />

2. Technical planning<br />

1<br />

3. Detailed planning by <strong>GM</strong> <strong>RAILING</strong> ®<br />

4. Approved plan by customer<br />

5. <strong>Product</strong>ion, delivery by <strong>GM</strong> <strong>RAILING</strong> ®<br />

6. Assembly, material delivery, installation support<br />

Comprehensive information about our glass railing systems such as brochures,<br />

tender texts, installation instructions and detailed solutions are available on our<br />

ePaper: epaper.glasmarte.at<br />

Please also refer to the particularly easy-to-use planning manuals of the<br />

<strong>GM</strong> <strong>RAILING</strong> ® UNI system. The shortest and cheapest way to go from an idea<br />

to an elegant glass balustrade.<br />

3<br />

5<br />

42 | <strong>GM</strong> <strong>RAILING</strong> ®

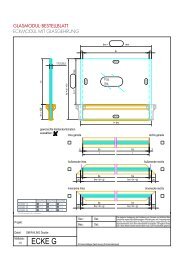

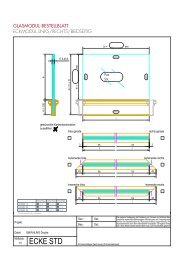

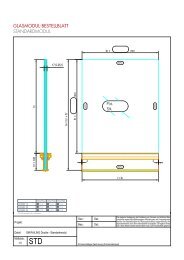

Querschnitt<br />

M 1 : 2<br />

40<br />

75<br />

Glas 16<br />

52<br />

41<br />

OKFF<br />

10<br />

KPO<br />

KPO<br />

KPO<br />

KPO<br />

41<br />

10<br />

41<br />

52<br />

Grundriss<br />

M 1 : 20<br />

A<br />

Ansicht<br />

M 1 : 20<br />

V<br />

Glas 1823<br />

KPO<br />

POS. 1.4<br />

KPO<br />

Einhängeprofil 1753<br />

Naturmaß 3587<br />

10<br />

Glas 1823<br />

KPO<br />

POS. 1.4<br />

KPO<br />

Einhängeprofil 1753<br />

Ansicht<br />

M 1 : 20<br />

Glas 1423<br />

KPO<br />

POS. 1.2<br />

KPO<br />

Einhängeprofil 1283<br />

Naturmaß 1397<br />

KPO<br />

10<br />

KPO<br />

KPO<br />

KPO<br />

Glas 1017<br />

A bb. Artikelnr.: P os. Stück L H nei gen1 s chwenk en1 s chwenk en2 nei gen2 B emer kung<br />

V SG 2X8 ESG 4xFolie 1.4 2 1823 1017 4x Klarfolie (1.52mm)<br />

V SG 2X8 ESG 4xFolie 1.3 2 1644 1017 4x Klarfolie (1.52mm)<br />

V SG 2X8 ESG 4xFolie 1.2 1 1423 1017 4x Klarfolie (1.52mm)<br />

V SG 2X8 ESG 4xFolie 1.1 1 1007 1017 4x Klarfolie (1.52mm)<br />

V SG 2X8 ESG 4xFolie 1.5 2 1999 1017 4x Klarfolie (1.52mm)<br />

504166 1.5 1 1999 90,00° 90,00° 90,00° 90,00°<br />

504166 *** 1.5 1 1929 90,00° 90,00° 90,00° 90,00°<br />

504166 *** 1.4 1 1753 90,00° 90,00° 90,00° 90,00°<br />

504166 *** 1.4 1 1753 90,00° 90,00° 90,00° 90,00°<br />

504166 *** 1.3 1 1574 90,00° 90,00° 90,00° 90,00°<br />

504166 *** 1.3 1 1574 90,00° 90,00° 90,00° 90,00°<br />

504166 *** 1.2 1 1283 90,00° 90,00° 90,00° 90,00°<br />

504166 *** 1.1 1 937 90,00° 90,00° 90,00° 90,00°<br />

564105 27<br />

564106 27<br />

564172 8<br />

564173 8<br />

564601 27<br />

*** A chtung! Kleben nach Plan<br />

Spedition:<br />

Montage:<br />

Abholung:<br />

Ergänzungen:<br />

Gezeichnet.: Harish Makwana<br />

Auftraggeber: Schlosserei Gräsel GmbH<br />

Kommission: EFH Gräsel, Riegelsberg<br />

Planinhalt<br />

140°<br />

Versand / <strong>GM</strong>:<br />

Glas intern + MB:<br />

Objektnummer:<br />

Auftragsnummer, Material:<br />

Auftragsnummer, Glas:<br />

Ansicht / Grundriss<br />

Querschnitt / Details<br />

Ausdruck vom:<br />

90°<br />

45°<br />

neigen 1 neigen 2<br />

schwenken 1 schwenken 2<br />

Verkehrsseite<br />

Abdeckung<br />

Achsen<br />

Bauseits<br />

Alu<br />

Beton<br />

Dämmung<br />

Edelstahl<br />

22.5° 22.5°<br />

L<br />

Freigabe<br />

ACHTUNG:<br />

45°<br />

Datum<br />

Bitte unterfertigt retour<br />

90°<br />

Sämtliche Maße und Details sind zu<br />

Kontrolliert und zur Ausführung freigegeben<br />

A.<br />

32409_F_V01_V001b<br />

Object - Glasbau - Elemente / <strong>GM</strong> <strong>RAILING</strong><br />

Datum: 20.03.2013<br />

Plan Nr.:<br />

B er ei ch :<br />

140°<br />

Glas<br />

Holz<br />

Kunststoff/Silikon<br />

UK/Profil<br />

Putz<br />

Stahl<br />

- Kantenschutz oder Handlaufanbindung falls erforderlich bauseits!<br />

- Anbindung an Baukörper und Abdichtung sind bauseitige Leistungen.<br />

- Dargestellte Abdichtungen in der Zeichnung sind schematisch.<br />

- Bauseitige Leistungen sind nicht gesondert hervor gehoben.<br />

- Lochbohrungen und Fräsungen in den Unterkonstruktionsprofilen sowie<br />

3D-Darstellungen sind als maßabhängige Symboldarstellungen zu verstehe<br />

kontrollieren und nach der Freigabe einzuhalten!<br />

Die Gläser werden nach diesen Plänen produziert!<br />

Gezeichnet:<br />

Das Urheberrecht an dieser Zeichnung und allen<br />

Empfänger anvertraut sind, verbleibt jederzeit un<br />

schriftliche Genehmigung dürfen sie nicht kopier<br />

niemals dritten Personen mitgeteilt oder zugängli<br />

A rt:<br />

Unte<br />

For t l<br />

Proje<br />

Blattgrös<br />

2<br />

Naturmaß = Stahlinnenkante<br />

Einzelheit Y<br />

Naturmaß = Stahlinnenkante 1397 Detail 3<br />

Naturmaß Naturmaß Naturmaß Naturmaß = Stahlinnenkante Stahlinnenkante Stahlinnenkante Stahlinnenkante 3336<br />

Ansicht<br />

M 1 : 20<br />

M 1 : 20<br />

Ansicht<br />

Detail 2<br />

Einhängeprofil 1999<br />

KPO<br />

POS. 1.5<br />

KPO<br />

Glas 1999<br />

Detail 3<br />

116°<br />

Naturmaß 3992<br />

Naturmaß 991<br />

Glas 1007<br />

KPO<br />

Ansicht<br />

M 1 : 20<br />

POS. 1.1<br />

KPO<br />

Einhängeprofil 937<br />

Gl as 1017<br />

Glasausstand 900<br />

Geländerhöhe 900<br />

Einhängeprofil 1929<br />

KPO<br />

POS. 1.5<br />

KPO<br />

Glas 1999<br />

90°<br />

Detail 1<br />

116°<br />

Naturmaß 3336<br />

Glas 1644<br />

Glas 1644<br />

Einhängeprofil 1574<br />

Einhängeprofil 1574<br />

Detail 2<br />

Naturmaß = Stahlinnenkante 991<br />

Ansicht<br />

M 1 : 20<br />

KPO<br />

KPO<br />

KPO<br />

KPO<br />

KPO<br />

KPO<br />

KPO<br />

P OS. 1.3<br />

KPO<br />

KPO<br />

KPO<br />

KPO<br />

P OS. 1.3<br />

KPO<br />

V<br />

A<br />

Absturzseite<br />

115<br />

Glaseinstand 115<br />

Detail 1<br />

A<br />

4<br />

V<br />

Naturmaß = Stahlinnenkante 3992<br />

H<br />

Naturmaß = Stahlinnenkante 3587<br />

railing<br />

A-6900 Bregenz, Brachsenweg 39, Tel.: +43 5574 6722-0, Fax: -544, www.glasmarte.at, railing@glasmarte.at<br />

6

Technical changes, as well as printing and typing errors reserved. | V190101<br />

Glas Marte GmbH | Brachsenweg 39 | A 6900 Bregenz<br />

T +43 5574 6722-0 | office@glasmarte.at I www.glasmarte.at