Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

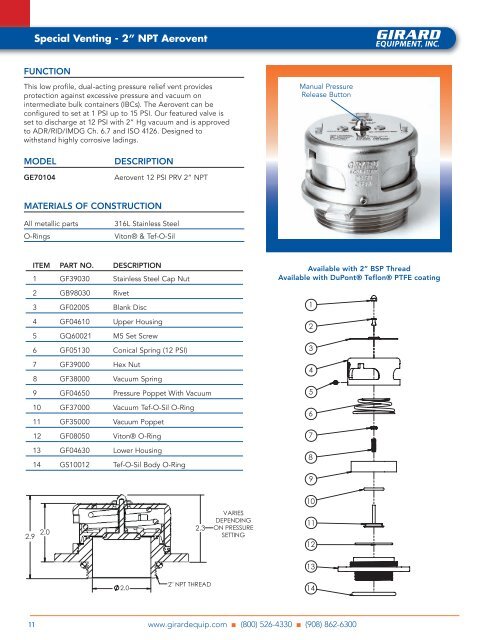

Special Venting - 2” NPT Aerovent<br />

FUNCTION<br />

This low profile, dual-acting pressure relief vent provides<br />

protection against excessive pressure and vacuum on<br />

intermediate bulk containers (IBCs). The Aerovent can be<br />

configured to set at 1 PSI up to 15 PSI. Our featured valve is<br />

set to discharge at 12 PSI with 2” Hg vacuum and is approved<br />

to ADR/RID/IMDG Ch. 6.7 and ISO 4126. Designed to<br />

withstand highly corrosive ladings.<br />

Manual Pressure<br />

Release Button<br />

MODEl<br />

GE70104<br />

DESCRIPTION<br />

6 5 4 3 2 1<br />

NOTES:<br />

ALL STAINLESS STEEL COMPONENTS<br />

5 GQ60021 M5 Set Screw<br />

Aerovent 12 PSI PRV 2” NPT<br />

REVISIONS<br />

REV. DESCRIPTION DATE APPROVED ECN<br />

A INITIAL RELEASE 3/2/15 CB 20150304<br />

12 PSIG MAWP<br />

B ADDED FLOW INFORMATION 6/15/15 CB 20150603<br />

FULL FLOW = 675 SCFM<br />

MATERIAlS OF CONSTRUCTION<br />

F<br />

CASE TEST<br />

1. REMOVE SPRING AND INSERT TEST PLUG.<br />

All metallic 7 2. parts AIR TEST FOR ONE 316L MINUTE Stainless 6 AT 18 PSIG. Steel NO LEAKS ALLOWED. 5 (BUBBLE LEAK TEST)<br />

4 3 2<br />

DESCRIPTION<br />

QTY.<br />

REVISIONS<br />

NOTES:<br />

REV.<br />

DESCRIPTION<br />

M5 O-Rings SEAT LEAKAGE TEST<br />

x 0.8 - 6mm Set Screw 1 Viton® & Tef-O-Sil<br />

1. REMOVE TEST PLUG AND REINSTALL SPRING. ALL STAINLESS STEEL COMPONENTS<br />

A<br />

INITIAL RELEASE<br />

Blank Disc, Euro Vent 2. RAPIDLY INCREASE 1 AIR PRESSURE AND BLOW OUT THE ASSEMBLY, ASSURE THAT THE O-RING DOES NOT UNSEAT.<br />

12 PSIG MAWP<br />

B<br />

ADDED FLOW INFORMATION<br />

Upper Housing 3. SLOWLY INCREASE 1 AIR PRESSURE UNTIL THE VALVE OPENS. START TO DISCHARGE IS 12 1.5 PSIG.<br />

4. DECREASE AIR PRESSURE AND WAIT FOR FULL THE FLOW VALVE = 675 TO SCFM RESEAT.<br />

VSK5(8)V Vacuum 5. O-Ring RESEAT PRESSURE 1 BETWEEN 9.5 PSIG AND 13.5 PSIG.<br />

tainless Steel ITEM Cap Nut PART NO. 1 DESCRIPTION<br />

CASE TEST<br />

Available with 2” BSP Thread<br />

Rivet, Vent, 5/32" VACUUM Diameter 2<br />

1. REMOVE SPRING AND INSERT TEST PLUG.<br />

1 1. GF39030 VACUUM TO BE SET Stainless AT 2 inHg Steel 1 inHg Cap 2. OR Nut AIR ACCORDING TEST FOR ONE TO MINUTE ORDERAT 18 PSIG. NO LEAKS Available ALLOWED. with (BUBBLE DuPont® LEAK TEST) Teflon® PTFE coating<br />

Body O-Ring Tef-O-Sil 1<br />

Euro Vent Viton® O-Ring 1<br />

SEAT LEAKAGE TEST<br />

2 GB98030 Rivet<br />

1. REMOVE TEST PLUG AND REINSTALL SPRING.<br />

Lower Housing 1<br />

2. RAPIDLY INCREASE AIR PRESSURE AND BLOW OUT THE ASSEMBLY, ASSURE THAT THE O-RING DOES NOT UNSEAT.<br />

E<br />

Conical Spring 12 PSI 1<br />

3. SLOWLY INCREASE AIR PRESSURE UNTIL THE VALVE OPENS. START TO DISCHARGE IS 12 1.5 PSIG.<br />

3 GF02005 Blank Disc 4. DECREASE AIR PRESSURE AND WAIT FOR THE VALVE TO RESEAT. 1<br />

Vacuum Spring 1<br />

5. RESEAT PRESSURE BETWEEN 9.5 PSIG AND 13.5 PSIG.<br />

Vacuum Poppet 1<br />

4 GF04610 Upper Housing VACUUM<br />

Hex Nut 1<br />

1. VACUUM TO BE SET AT 2 inHg 1 inHg OR ACCORDING 2TO ORDER<br />

essure Poppet With Vacuum 1<br />

6 GF05130 Conical Spring (12 PSI)<br />

3<br />

1<br />

7 GF39000 Hex Nut<br />

4<br />

2<br />

8 GF38000 Vacuum Spring<br />

9 GF04650 Pressure Poppet With Vacuum<br />

5<br />

3<br />

D<br />

10 GF37000 Vacuum Tef-O-Sil O-Ring<br />

11 GF35000 Vacuum Poppet<br />

12 GF08050 Viton® O-Ring<br />

6<br />

7<br />

4<br />

5<br />

2.0<br />

2.9<br />

13 GF04630 Lower Housing<br />

14 GS10012 Tef-O-Sil Body O-Ring<br />

2.0<br />

2.3<br />

2" NPT THREAD<br />

VARIES<br />

DEPENDING<br />

ON PRESSURE<br />

SETTING<br />

2.3<br />

VARIES<br />

DEPENDING<br />

ON PRESSURE<br />

SETTING<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

C<br />

B<br />

2.0<br />

2" NPT THREAD<br />

14<br />

13<br />

14<br />

11 www.girardequip.com n (800) 526-4330 n (908) 862-6300