Mpumalanga Business 2020-21 edition

The 2020/21 edition of Mpumalanga Business is the 11th issue of this essential publication that since its launch in 2008 has established itself as the premier business and investment guide for the province. Updated overviews of each of the key economic sectors of the province are included, with references to the latest investments by companies across multiple sectors. These include Sappi, Sasol and Sonae Arauco, which is expanding its White River factory. Afrimat is considering investment in the mining sector, while Exxaro Resources, South32 and Pan African Resources are among the mining companies spending on extending the life of existing mines. A useful article on what incentives are available to investors from various departments and agencies is provided. Mpumalanga has several investment and business opportunities in a wide range of sectors.

The 2020/21 edition of Mpumalanga Business is the 11th issue of this essential publication that since its launch in 2008 has established itself as the premier business and investment guide for the province. Updated overviews of each of the key economic sectors of the province are included, with references to the latest investments by companies across multiple sectors. These include Sappi, Sasol and Sonae Arauco, which is expanding its White River factory. Afrimat is considering investment in the mining sector, while Exxaro Resources, South32 and Pan African Resources are among the mining companies spending on extending the life of existing mines. A useful article on what incentives are available to investors from various departments and agencies is provided. Mpumalanga has several investment and business opportunities in a wide range of sectors.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

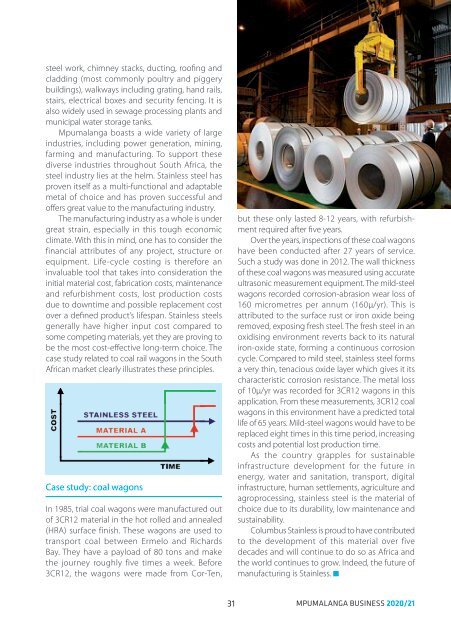

steel work, chimney stacks, ducting, roofing and<br />

cladding (most commonly poultry and piggery<br />

buildings), walkways including grating, hand rails,<br />

stairs, electrical boxes and security fencing. It is<br />

also widely used in sewage processing plants and<br />

municipal water storage tanks.<br />

<strong>Mpumalanga</strong> boasts a wide variety of large<br />

industries, including power generation, mining,<br />

farming and manufacturing. To support these<br />

diverse industries throughout South Africa, the<br />

steel industry lies at the helm. Stainless steel has<br />

proven itself as a multi-functional and adaptable<br />

metal of choice and has proven successful and<br />

offers great value to the manufacturing industry.<br />

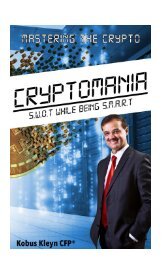

The manufacturing industry as a whole is under<br />

great strain, especially in this tough economic<br />

climate. With this in mind, one has to consider the<br />

financial attributes of any project, structure or<br />

equipment. Life-cycle costing is therefore an<br />

invaluable tool that takes into consideration the<br />

initial material cost, fabrication costs, maintenance<br />

and refurbishment costs, lost production costs<br />

due to downtime and possible replacement cost<br />

over a defined product’s lifespan. Stainless steels<br />

generally have higher input cost compared to<br />

some competing materials, yet they are proving to<br />

be the most cost-effective long-term choice. The<br />

case study related to coal rail wagons in the South<br />

African market clearly illustrates these principles.<br />

Case study: coal wagons<br />

In 1985, trial coal wagons were manufactured out<br />

of 3CR12 material in the hot rolled and annealed<br />

(HRA) surface finish. These wagons are used to<br />

transport coal between Ermelo and Richards<br />

Bay. They have a payload of 80 tons and make<br />

the journey roughly five times a week. Before<br />

3CR12, the wagons were made from Cor-Ten,<br />

but these only lasted 8-12 years, with refurbishment<br />

required after five years.<br />

Over the years, inspections of these coal wagons<br />

have been conducted after 27 years of service.<br />

Such a study was done in 2012. The wall thickness<br />

of these coal wagons was measured using accurate<br />

ultrasonic measurement equipment. The mild-steel<br />

wagons recorded corrosion-abrasion wear loss of<br />

160 micrometres per annum (160μ/yr). This is<br />

attributed to the surface rust or iron oxide being<br />

removed, exposing fresh steel. The fresh steel in an<br />

oxidising environment reverts back to its natural<br />

iron-oxide state, forming a continuous corrosion<br />

cycle. Compared to mild steel, stainless steel forms<br />

a very thin, tenacious oxide layer which gives it its<br />

characteristic corrosion resistance. The metal loss<br />

of 10μ/yr was recorded for 3CR12 wagons in this<br />

application. From these measurements, 3CR12 coal<br />

wagons in this environment have a predicted total<br />

life of 65 years. Mild-steel wagons would have to be<br />

replaced eight times in this time period, increasing<br />

costs and potential lost production time.<br />

As the country grapples for sustainable<br />

infrastructure development for the future in<br />

energy, water and sanitation, transport, digital<br />

infrastructure, human settlements, agriculture and<br />

agroprocessing, stainless steel is the material of<br />

choice due to its durability, low maintenance and<br />

sustainability.<br />

Columbus Stainless is proud to have contributed<br />

to the development of this material over five<br />

decades and will continue to do so as Africa and<br />

the world continues to grow. Indeed, the future of<br />

manufacturing is Stainless. ■<br />

31 MPUMALANGA BUSINESS <strong>2020</strong>/<strong>21</strong>